| ... | Regulation | a0c0 | ||||||||||||||||||||||||||||||

| ... | 1. Scope | a0c0 | ||||||||||||||||||||||||||||||

| ... | 2. Definitions | a0c0 | ||||||||||||||||||||||||||||||

| ... | 3. Application for approval | a0c0 | ||||||||||||||||||||||||||||||

| ... | 4. Approval | a0c0 | ||||||||||||||||||||||||||||||

| ... | 5. Requirements | a0c0 | ||||||||||||||||||||||||||||||

| ... | 6. Modifications and extension of approval of the vehicle type | a0c0 | ||||||||||||||||||||||||||||||

| ... | 7. Conformity of production | a0c0 | ||||||||||||||||||||||||||||||

| ... | 8. Penalties for non-conformity of production | a0c0 | ||||||||||||||||||||||||||||||

| ... | 9. Production definitely discontinued | a0c0 | ||||||||||||||||||||||||||||||

| ... | a2c0 | |||||||||||||||||||||||||||||||

| ... | ANNEXES | a0c0 | ||||||||||||||||||||||||||||||

| ... | Annex 1 - Communication concerning the approval or extension or refusal or withdrawal of approval or production definitely discontinued of a vehicle type with regard to the arrangement of foot controls, pursuant to Regulation No. 35 | a0c0 | ||||||||||||||||||||||||||||||

| ... | Annex 2 - Arrangements of approval marks | a0c0 | ||||||||||||||||||||||||||||||

| ... | Annex 3 - Procedure for determining the H point and the actual torso angle for seating positions in motor vehicles | a0c0 | ||||||||||||||||||||||||||||||

| ... | Annex 4 - Arrangement of foot controls | a0c0 | ||||||||||||||||||||||||||||||

| 1. |

|

a0c0 | ||||||||||||||||||||||||||||||

| ... |

This Regulation applies to vehicles of category M1 1/ with regard to the arrangement and mode of operation of the foot controls. |

a1c0 | ||||||||||||||||||||||||||||||

| [1] |

As defined in the Consolidated Resolution on the Construction of Vehicles (R.E.3), document ECE/TRANS/WP.29/78/Rev.6, para. 2 - www.unece.org/trans/main/wp29/wp29wgs/wp29gen/wp29resolutions.html |

a2c0 | ||||||||||||||||||||||||||||||

| 2. |

|

a0c0 | ||||||||||||||||||||||||||||||

| ... | For the purpose of this Regulation: | a0c0 | ||||||||||||||||||||||||||||||

| 2.1. | "approval of a vehicle" means the approval of a vehicle type with regard to the foot controls as specified in paragraph 1; | a0c0 | ||||||||||||||||||||||||||||||

| 2.2. | "private (passenger) car" means a motor vehicle, other than a motor cycle, designed to carry not more than nine persons; | a0c0 | ||||||||||||||||||||||||||||||

| 2.3. | "vehicle type" means a category of motor vehicles which do not differ in respect of the structure and internal arrangements which may affect the location and operation of the foot controls; | a0c0 | ||||||||||||||||||||||||||||||

| 2.4. | "accelerator pedal" means a foot control by which the engine power output can be varied; | a0c0 | ||||||||||||||||||||||||||||||

| 2.5. | "Service-brake pedal" means a foot control by which the service braking device can be operated; | a0c0 | ||||||||||||||||||||||||||||||

| 2.6. | "clutch pedal" means the foot control of the device designed to engage the engine with or disengage it from the transmission and the road wheels; | a0c0 | ||||||||||||||||||||||||||||||

| 2.7. | "transverse plane" means a plane perpendicular to the median longitudinal plane of the vehicle; | a0c0 | ||||||||||||||||||||||||||||||

| 2.8. | "longitudinal plane" means a plane parallel to the median longitudinal plane of the vehicle; | a0c0 | ||||||||||||||||||||||||||||||

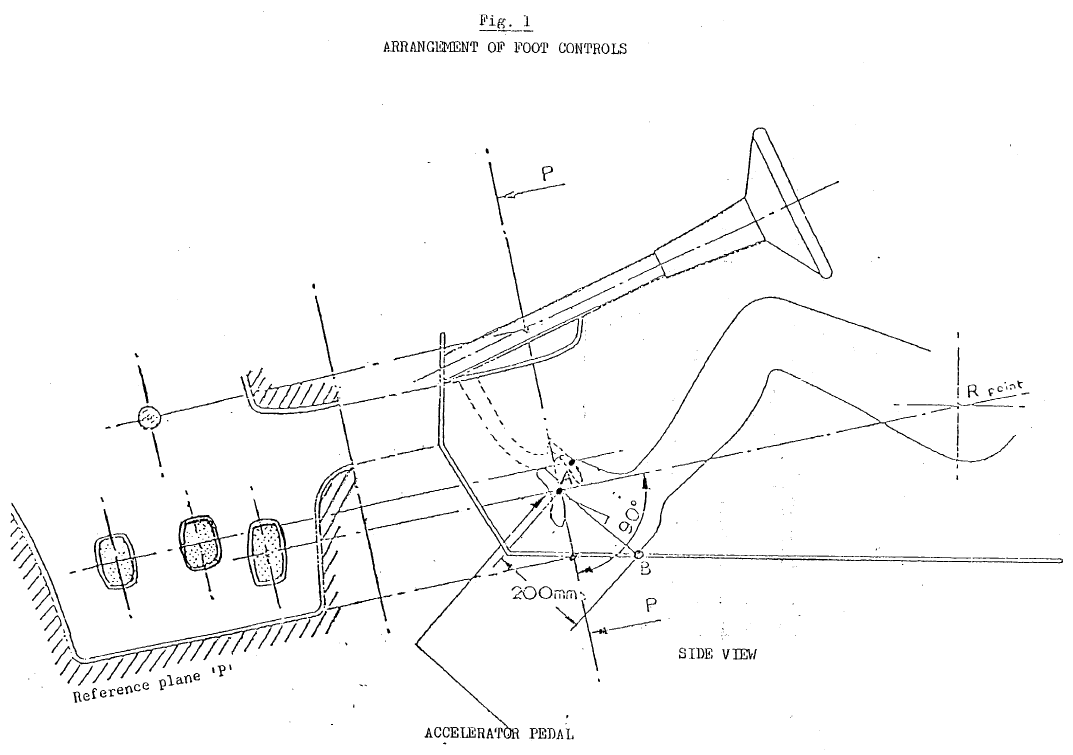

| 2.9. |

"reference plane 'P' " (see fig.1) means a transverse plane perpendicular to the straight line connecting point "R" to point "A", where |

a0c0 | ||||||||||||||||||||||||||||||

| 2.9.1. | "A" is a point on the surface of the accelerator pedal 200 mm from point "B"; | a0c0 | ||||||||||||||||||||||||||||||

| 2.9.2. |

"B" is the fixed point on the vehicle corresponding to the heel point, as established by the vehicle manufacturer;

|

a0c0 | ||||||||||||||||||||||||||||||

| 2.10. | "walls" means fixed structural members (e.g. transmission tunnel; wheel arches; side trim panels). | a0c0 | ||||||||||||||||||||||||||||||

| 3. |

|

a0c0 | ||||||||||||||||||||||||||||||

| 3.1. | The application for approval of a vehicle type with regard to the arrangement of foot controls shall be submitted by the vehicle manufacturer or by his duly accredited representative. | a0c0 | ||||||||||||||||||||||||||||||

| 3.2. | It shall be accompanied by the following documents in triplicate, and by the following particulars: | a0c0 | ||||||||||||||||||||||||||||||

| 3.2.1. | drawings, on an appropriate scale and in sufficient detail, of the parts of the structure considered to be referred to by the requirements of this Regulation; | a0c0 | ||||||||||||||||||||||||||||||

| 3.3. | A vehicle representative of the type to be approved shall be submitted to the technical service responsible for conducting the approval tests. | a0c0 | ||||||||||||||||||||||||||||||

| 4. |

|

a0c0 | ||||||||||||||||||||||||||||||

| 4.1. | If the vehicle type submitted for approval pursuant to this Regulation meets the requirements of paragraph 5, below, approval of that vehicle type shall be granted. | a0c0 | ||||||||||||||||||||||||||||||

| 4.2. |

An approval number shall be assigned to each type approved. Its first two digits (at present 01) shall indicate the series of amendments incorporating the most recent major technical amendments made to the UN Regulation at the time of issue of the approval. The same Contracting Party shall not assign the same number to another vehicle type. |

a2c0 | ||||||||||||||||||||||||||||||

| 4.3. | Notice of approval or of extension or of refusal or withdrawal of approval or production definitely discontinued of a vehicle type pursuant to this Regulation shall be communicated to the Parties to the Agreement which apply this Regulation by means of a form conforming to the model in annex 1 to this Regulation. | a0c0 | ||||||||||||||||||||||||||||||

| 4.4. | There shall be affixed, conspicuously and in a readily accessible place specified on the approval form, to every vehicle conforming to a vehicle type approved under this Regulation on international approval mark consisting of: | a0c0 | ||||||||||||||||||||||||||||||

| 4.4.1. |

a circle surrounding the letter "E" followed by the distinguishing number of the country which had granted approval; 2/ and |

a1c0 | ||||||||||||||||||||||||||||||

|

|

The distinguishing numbers of the Contracting Parties to the 1958 Agreement are reproduced in Annex 3 to the Consolidated Resolution on the Construction of Vehicles (R.E.3), document ECE/TRANS/WP.29/78/Rev.6, Annex 3 - www.unece.org/trans/main/wp29/wp29wgs/wp29gen/wp29resolutions.html |

a2c0 | ||||||||||||||||||||||||||||||

| 4.4.2. | the number of this Regulation, followed by the letter "R", a dash and the approval number to the right of the circle prescribed in paragraph 4.4.1. | a0c0 | ||||||||||||||||||||||||||||||

| 4.5. | If the vehicle conforms to a vehicle type approved, under one or more other Regulations annexed to the Agreement, in the country which has granted approval under this Regulation, the symbol prescribed in paragraph 4.4.1 need not be repeated; in such a case the additional numbers and symbols of all the Regulations under which approval has been granted in the country which has granted approval under this Regulation shall be placed in vertical columns to the right of the symbol prescribed in paragraph 4.4.1. | a0c0 | ||||||||||||||||||||||||||||||

| 4.6. | The approval mark shall be clearly legible and be indelible. | a0c0 | ||||||||||||||||||||||||||||||

| 4.7. | The approval mark shall be placed close to or on the vehicle data plate affixed by the manufacturer. | a0c0 | ||||||||||||||||||||||||||||||

| 4.8. | Annex 2 to this Regulation gives examples of arrangements of approval marks. | a0c0 | ||||||||||||||||||||||||||||||

| 5. |

|

a0c0 | ||||||||||||||||||||||||||||||

| 5.1. | The foot controls shall be arranged in the following order from left to right, as observed from the driver's seat: clutch pedal if any; service-brake pedal; accelerator pedal. | a0c0 | ||||||||||||||||||||||||||||||

| 5.2. | It shall be possible to place the left foot normally in a position of rest on the floor surface or foot rest such that it is not trapped by the pedals. | a0c0 | ||||||||||||||||||||||||||||||

| 5.3. | It shall be possible to actuate any pedal over its full travel without inadvertently operating floor-switches or other foot controls. | a0c0 | ||||||||||||||||||||||||||||||

| 5.4. | The distance, shown at "E" in annex 4, between the contour points of the orthogonal projections on to plane "P" of the accelerator-pedal and service-brake-pedal bearing surfaces shall be &le 100 mm &ge 50 mm. | a0c0 | ||||||||||||||||||||||||||||||

| 5.5. |

The distance, shown at "F" in annex 4, between the orthogonal projections of the service-brake-pedal and the clutch-pedal bearing surfaces on to the reference plane "P" shall be ≥ 50 mm. |

a2c0 | ||||||||||||||||||||||||||||||

| 5.6. |

The distance, shown at "G" in annex 4, between the contour points of the projection of the clutch pedal on to plane "P" and the intersection of the nearest wall with plane "P" shall be ≥ 50 mm. |

a2c0 | ||||||||||||||||||||||||||||||

| 5.7. |

The distances, respectively shown as "H" and "J" in Annex 4, between the projection of the service-brake pedal on to the reference plane "P" and the intersection of each of the walls with that plane shall be ≥ 130 mm to the right and ≥ 160 mm to the left for vehicles with three pedals, and ≥ 130 mm to the right and ≥ 120 mm to the left for vehicles with two pedals. |

a2c0 | ||||||||||||||||||||||||||||||

| 6. |

|

a0c0 | ||||||||||||||||||||||||||||||

| 6.1. | Every modification of the vehicle type shall be notified to the administrative department which approved the vehicle type. The department may then either: | a0c0 | ||||||||||||||||||||||||||||||

| 6.1.1. | consider that the modifications made are unlikely to have appreciable adverse effects, and that in any case the vehicle still meets the requirements; or | a0c0 | ||||||||||||||||||||||||||||||

| 6.1.2. | require a further test report from the technical service responsible for conducting the tests; | a0c0 | ||||||||||||||||||||||||||||||

| 6.2. | Confirmation or refusal of approval, specifying the alterations, shall be communicated by the procedure specified in paragraph 4.3. above to the Parties to the Agreement which apply this Regulation. | a0c0 | ||||||||||||||||||||||||||||||

| 6.3. | The competent authority issuing the extension of approval shall assign a series number for such an extension and inform thereof the other Parties to the 1958 Agreement applying this Regulation by means of a communication form conforming to the model in annex 1 to this Regulation. | a0c0 | ||||||||||||||||||||||||||||||

| 7. |

|

a0c0 | ||||||||||||||||||||||||||||||

| ... |

The conformity of production procedures shall comply with those set out in the Agreement, Schedule 1 (E/ECE/TRANS/505/Rev.3), with the following requirements: |

a2c0 | ||||||||||||||||||||||||||||||

| 7.1. | Every vehicle bearing an approval mark as prescribed under this Regulation shall conform to the vehicle type approved, more particularly as regards the arrangement of foot controls; | a0c0 | ||||||||||||||||||||||||||||||

| 7.2. | In order to verify conformity as prescribed in paragraph 7.1. above, a sufficient number of serially-produced vehicles bearing the approval mark required by this Regulation shall be subjected to random checks. | a0c0 | ||||||||||||||||||||||||||||||

| 8. |

|

a0c0 | ||||||||||||||||||||||||||||||

| 8.1. | The approval granted in respect of a vehicle type pursuant to this Regulation may be withdrawn if the requirement laid down in paragraph 7.1. above is not complied with or if the vehicle fails to pass the test provided for in paragraph 7.2 above. | a0c0 | ||||||||||||||||||||||||||||||

| 8.2. | If a Party to the Agreement which applies this Regulation withdraws an approval it has previously granted, it shall forthwith notify the other Parties to the Agreement which apply this Regulation thereof by means of a communication form conforming to the model in Annex 1 to this Regulation. | a0c0 | ||||||||||||||||||||||||||||||

| 9. |

|

a0c0 | ||||||||||||||||||||||||||||||

| ... | If the holder of the approval completely ceases to manufacture a vehicle type approved in accordance with this Regulation, he shall so inform the authority which granted the approval. Upon receiving the relevant communication that authority shall inform thereof the other Parties to the 1958 Agreement applying this Regulation by means of a communication form conforming to the model in annex 1 to this Regulation. | a0c0 | ||||||||||||||||||||||||||||||

| 10. |

|

a2c0 | ||||||||||||||||||||||||||||||

| 10.1. |

As from the official date of entry into force of the 01 series of amendments, no Contracting Party applying this Regulation shall refuse to grant or refuse to accept type approvals under this Regulation as amended by the 01 series of amendments. |

a2c0 | ||||||||||||||||||||||||||||||

| 10.2. |

As from 1 September 2022, Contracting Parties applying this Regulation shall not be obliged to accept type approvals to the preceding series of amendments, first issued after 1 September 2022. |

a2c0 | ||||||||||||||||||||||||||||||

| 10.3. |

Contracting Parties applying this Regulation shall continue to accept type approvals issued according to the preceding series of amendments to this Regulation first issued before 1 September 2022. |

a2c0 | ||||||||||||||||||||||||||||||

| 10.4. |

Contracting Parties applying this Regulation shall not refuse to grant type approvals according to any preceding series of amendments to this Regulation or extensions thereof. |

a2c0 | ||||||||||||||||||||||||||||||

|

|

|

a2c0 | ||||||||||||||||||||||||||||||

| ... | The Parties to the Agreement which apply this Regulation shall communicate to the Secretariat of the United Nations the names and addresses of the technical services conducting approval tests and of the administrative departments which grant approval and to which forms certifying approval or refusal or withdrawal of approval, issued in other countries, are to be sent. | a0c0 | ||||||||||||||||||||||||||||||

| ... |

|

a0c0 | ||||||||||||||||||||||||||||||

| A1 |

|

a0c0 | ||||||||||||||||||||||||||||||

| A1 |

|

a0c0 | ||||||||||||||||||||||||||||||

| A1 |

|

a2c0 | ||||||||||||||||||||||||||||||

| A1 [1] | Distinguishing number of the country which has granted/extended/refused/withdrawn/approval (see approval provisions in the Regulation). | a0c0 | ||||||||||||||||||||||||||||||

| A1 [2] | Strike out what does not apply. | a0c0 | ||||||||||||||||||||||||||||||

| A2 |

|

a0c0 | ||||||||||||||||||||||||||||||

| A2 |

|

a2c0 | ||||||||||||||||||||||||||||||

| A2 |

The above approval mark affixed to a vehicle shows that the vehicle type concerned has, with regard to the arrangement of foot controls, been approved in the Netherlands (E 4) under approval number 012439. The first two digits of the approval number indicate that the approval was granted in accordance with the requirements of UN Regulation No. 35, as amended by the 01 series of amendments. |

a2c0 | ||||||||||||||||||||||||||||||

| A2 |

|

a2c0 | ||||||||||||||||||||||||||||||

| A2 |

The above approval mark affixed to a vehicle shows that the vehicle type concerned has been approved in the Netherlands (E 4) pursuant to UN Regulation Nos. 35 and 24.[1] (In the case of the latter UN Regulation the corrected absorption co-efficient is 1.30 m-1). The first two digits of the approval numbers indicate that, at the date on which the respective approvals were granted, UN Regulation No. 35 included the 01 series of amendments and UN Regulation No. 24 included the 03 series of amendments. |

a2c0 | ||||||||||||||||||||||||||||||

| A2 [1] | The second number is given merely as an example. | a0c0 | ||||||||||||||||||||||||||||||

| A3 |

|

a2c0 | ||||||||||||||||||||||||||||||

| A3 1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 [1] |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.1.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.1.2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.3. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.4. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.5. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.6. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.7. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.8. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.9. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.10. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.11. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.1.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.1.2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.1.3. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.2.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.2.2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.2.3. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.2.4. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.2.5. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.3. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.4. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 [2] |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.5. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.6. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.7. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.7.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.7.1.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.7.1.2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.7.2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.7.3. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.8. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.9. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.9.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.9.2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.10. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.11. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.12. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.13. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.14. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.14.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.14.2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.15. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.16. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.16.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 4.16.2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 |

|

a2c0 | ||||||||||||||||||||||||||||||

| A3 [*] |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 |

|

a2c0 | ||||||||||||||||||||||||||||||

| A3 1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 [*] |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 |

|

a2c0 | ||||||||||||||||||||||||||||||

| A3 1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 2.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.1.1. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.1.2. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 3.1.3. |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 [*] |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 |

[DEL] |

a2c0 | ||||||||||||||||||||||||||||||

| A3 [1] |

The procedure is described in Annex 1 and its Appendices 1, 2 and 3 to the Consolidated Resolution on the Construction of Vehicles (R.E.3) (document ECE/TRANS/WP.29/78/Rev.6 - www.unece.org/trans/main/wp29/wp29wgs/wp29gen/wp29resolutions.html |

a2c0 | ||||||||||||||||||||||||||||||

| A4 |

|

a0c0 | ||||||||||||||||||||||||||||||

| A4 |

|

a2c0 | ||||||||||||||||||||||||||||||

| A4 |

|

a2c0 | ||||||||||||||||||||||||||||||

| A4 |

|

a2c0 | ||||||||||||||||||||||||||||||

| A4 |

|

a2c0 | ||||||||||||||||||||||||||||||

| A4 |

|

a2c0 |

Regulation UN No. 35 (Rev.1)

Foot controls

Consolidated up to

Series 01

dated: 09.06.2021

.png)

.png)

.png)

.png)

.png)

.png)

.png)