|

|

|

a6c0 | ||

| ... |

|

a0c0 | ||

| ... | Regulation | a0c0 | ||

| ... | A Administrative provisions | a0c0 | ||

| ... | Scope | a0c0 | ||

| ... | 1. Definitions | a0c0 | ||

| ... | 2. Application for approval of a headlamp | a0c0 | ||

| ... | 3. Markings | a0c0 | ||

| ... | 4. Approval | a0c0 | ||

| ... | B. Technical requirements for headlamps | a0c0 | ||

| ... | 5. General specifications | a0c0 | ||

| ... | 6. Illumination | a0c0 | ||

| ... | 7. Colour | a0c0 | ||

| ... | 8. Gauging of discomfort | a0c0 | ||

| ... | C. Further administrative provisions | a0c0 | ||

| ... | 9. Modification of the headlamp type and extension of approval | a0c0 | ||

| ... | 10. Conformity of production | a0c0 | ||

| ... | 11. Penalties for non conformity of production | a0c0 | ||

| ... | 12. Production definitively discontinued | a0c0 | ||

| ... | 13. Names and addresses of Technical Services responsible for conducting approval tests and of Type Approval Authorities | a0c0 | ||

| ... | 14. Transitional provisions | a0c0 | ||

| ... | Annexes | a0c0 | ||

| ... | 1 Communication | a0c0 | ||

| ... | 2 Examples of arrangements of approval marks | a0c0 | ||

| ... | 3 Spherical coordinate measuring system and test point locations | a0c0 | ||

| ... | 4 Tests for stability of photometric performance of headlamps in operation | a0c0 | ||

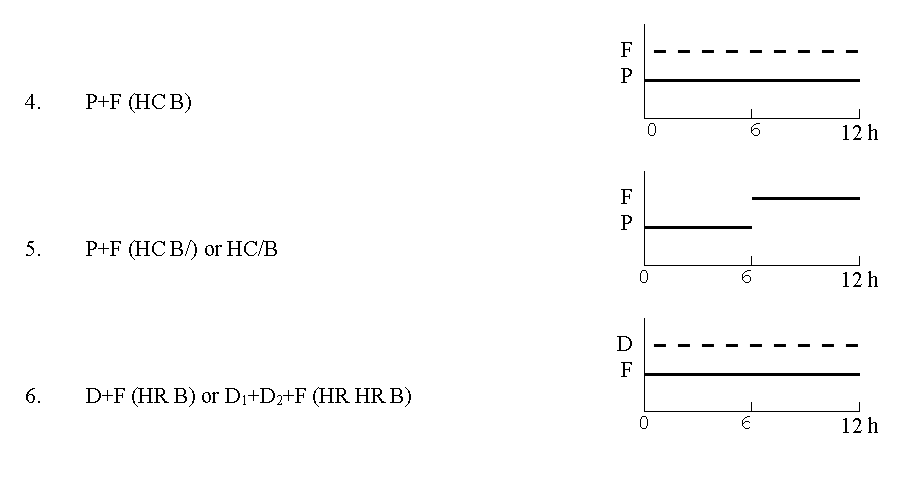

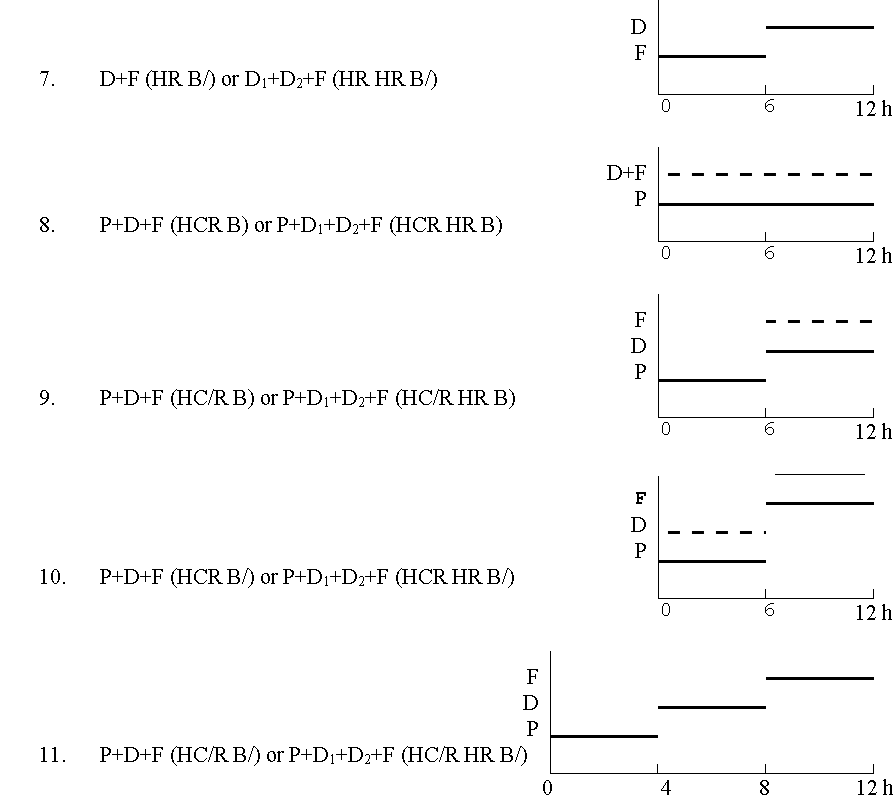

| ... | Appendix 1 - Overview of operational periods concerning test for stability of photometric performance | a0c0 | ||

| ... | 5 Minimum requirements for conformity of production control procedures | a0c0 | ||

| ... | 6 Requirements for lamps incorporating lenses of plastic material - Testing of lens or material samples and of complete lamps | a0c0 | ||

| ... | Appendix 1 - Chronological order of approval tests | a0c0 | ||

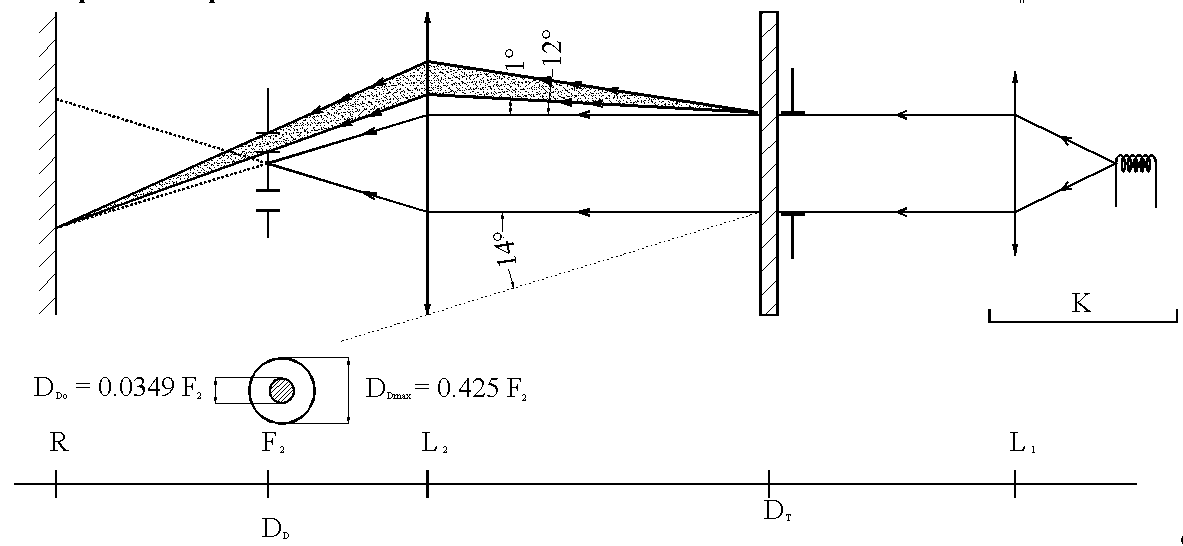

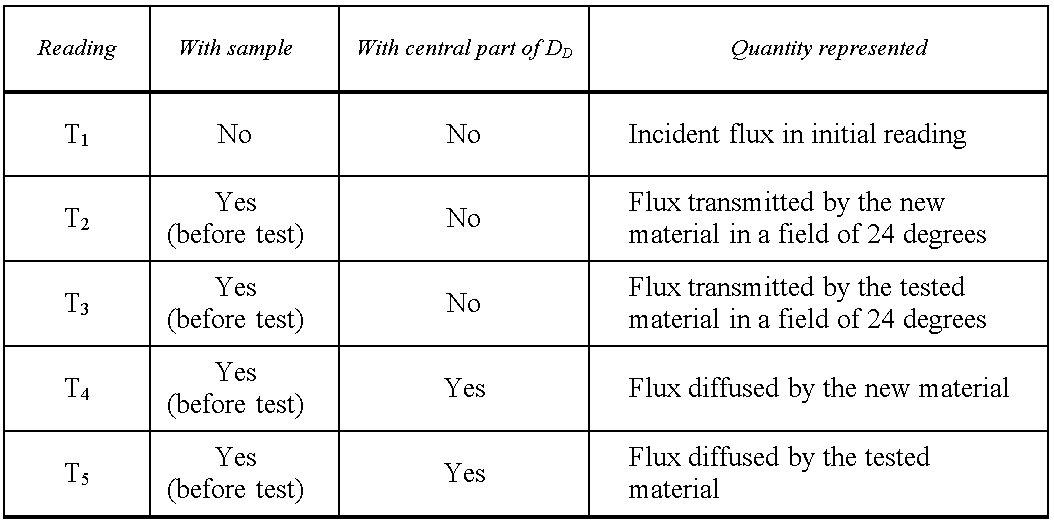

| ... | Appendix 2 - Method of measurement of the diffusion and transmission of light | a0c0 | ||

| ... | Appendix 3 - Spray testing method | a0c0 | ||

| ... | Appendix 4 - Adhesive tape adherence test | a0c0 | ||

| ... | 7 Minimum requirements for sampling by an inspector | a0c0 | ||

| ... | 8 Overview of operational periods concerning tests for stability of photometric performance | a0c0 | ||

| ... | 9 Instrumental verification of the "cut-off" for passing-beam headlamps | a0c0 | ||

| ... | 10 Requirements for LED modules and headlamps including LED modules | a0c0 | ||

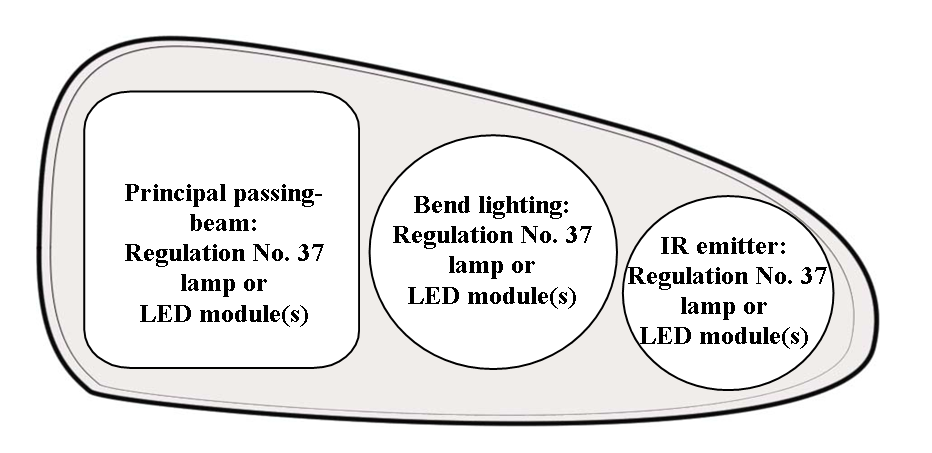

| ... | 11 A general illustration for principal passing-beam and beam contributors and correlated light source options | a0c0 | ||

| ... |

|

a0c0 | ||

| ... |

|

a0c0 | ||

| ... | This Regulation applies to headlamps for vehicles of categories L, M, N and T[2]. | a0c0 | ||

|

|

|

a0c0 | ||

|

|

|

a0c0 | ||

| 1. |

|

a0c0 | ||

| ... | For the purpose of this Regulation, | a0c0 | ||

| 1.1. | "Lens" means the outermost component of the headlamp (unit) which transmits light through the illuminating surface; | a0c0 | ||

| 1.2. | "Coating" means any product or products applied in one or more layers to the outer face of a lens; | a0c0 | ||

| 1.3. | "Headlamps of different types" means headlamps which differ in such essential respects as: | a1c0 | ||

| 1.3.1. | The trade name or mark: | a4c0 | ||

| ... |

|

a4c0 | ||

| ... |

|

a4c0 | ||

| 1.3.2. | The characteristics of the optical system; | a1c0 | ||

| 1.3.3. | The inclusion or elimination of components capable of altering the optical effects by reflection, refraction, absorption and/or deformation during operation; | a1c0 | ||

| 1.3.4. | Suitability for right-hand or left-hand traffic or for both traffic systems; | a1c0 | ||

| 1.3.5. | The kind of beam produced (passing beam, driving beam or both); | a1c0 | ||

| 1.3.6. |

|

a1c0 | ||

|

|

The category of filament lamp used and/or the LED module specific identification code(s). | a1c0 | ||

|

|

However, a device intended for the installation on the left side of the vehicle and the corresponding device intended for the installation on the right side of the vehicle shall be considered to be of the same type. | a1c0 | ||

| 1.4. | Headlamps of different "Classes" (A or B) mean headlamps identified by particular photometric provisions. | a0c0 | ||

| 1.5. | The definitions given in Regulation No. 48 and its series of amendments in force at the time of application for type approval shall apply to this Regulation. | a0c0 | ||

| 1.6. |

References made in this Regulation to standard (étalon) filament lamp(s) and to Regulation No. 37 shall refer to Regulation No. 37 and its series of amendments in force at the time of application for type approval. |

a0c0 | ||

| 2. |

|

a0c0 | ||

| 2.1. | The application for approval shall be submitted by the owner of the trade name or mark or by his duly accredited representative. It shall specify: | a0c0 | ||

| 2.1.1. | Whether the headlamp is intended to provide both a passing-beam and a driving-beam or only one of these beams; | a0c0 | ||

| 2.1.2. | Whether, if the headlamp is intended to provide a passing-beam, it is designed for both left-hand and right-hand traffic or for either left-hand or right-hand traffic only; | a0c0 | ||

| 2.1.3. | If the headlamp is equipped with an adjustable reflector, the mounting position(s) of the headlamp in relation to the ground and the longitudinal median plane of the vehicle; | a0c0 | ||

| 2.1.4. | Whether it concerns a Class A or B headlamp; | a0c0 | ||

| 2.1.5. | The category of the filament lamp(s) used, as listed in Regulation No. 37 and its series of amendments in force at the time of application for type approval, and/or the light source module specific identification code(s) for LED modules, if available. | a0c0 | ||

| 2.2. | Every application for approval shall be accompanied by: | a0c0 | ||

| 2.2.1. | Drawings in triplicate in sufficient detail to permit identification of the type and representing a frontal view of the headlamp, with details of lens ribbing if any, and the cross section. The drawings shall indicate the space(s) reserved for the approval mark and in case of LED module(s) also the space reserved for the specific identification code(s) of the module(s); | a0c0 | ||

| 2.2.1.1. | If the headlamp is equipped with an adjustable reflector, an indication of the mounting position(s) of the headlamp in relation to the ground and the longitudinal median plane of the vehicle, if the headlamp is for use in that (those) position(s) only; | a0c0 | ||

| 2.2.2. | A brief technical description including, in the case where headlamps are used to produce bend lighting, the extreme positions according to paragraph 6.2.7. below. In the case of LED module(s) this shall include: | a0c0 | ||

| ... | (a)A brief technical specification of the LED module(s); | a0c0 | ||

| ... | (b)A drawing with dimensions and the basic electrical and photometric values and the objective luminous flux and for each LED module a statement whether it is replaceable or not; | a0c0 | ||

| ... | (c)In case of electronic light source control gear, information on the electrical interface necessary for approval testing; | a0c0 | ||

| 2.2.3. | Two samples of each type of headlamp, one sample intended for the installation on the left side of the vehicle and one sample intended for the installation of the right side of the vehicle. | a0c0 | ||

| 2.2.4. | For the test of plastic material of which the lenses are made: | a0c0 | ||

| 2.2.4.1. | Fourteen lenses; | a0c0 | ||

| 2.2.4.1.1. | Ten of these lenses may be replaced by ten samples of material at least 60 x 80 mm in size, having a flat or convex outer surface and a substantially flat area (radius of curvature not less than 300 mm) in the middle measuring at least 15 x 15 mm; | a0c0 | ||

| 2.2.4.1.2. | Every such lens or sample of material shall be produced by the method to be used in mass production; | a0c0 | ||

| 2.2.4.2. | A reflector to which the lenses can be fitted in accordance with the manufacturer's instructions. | a0c0 | ||

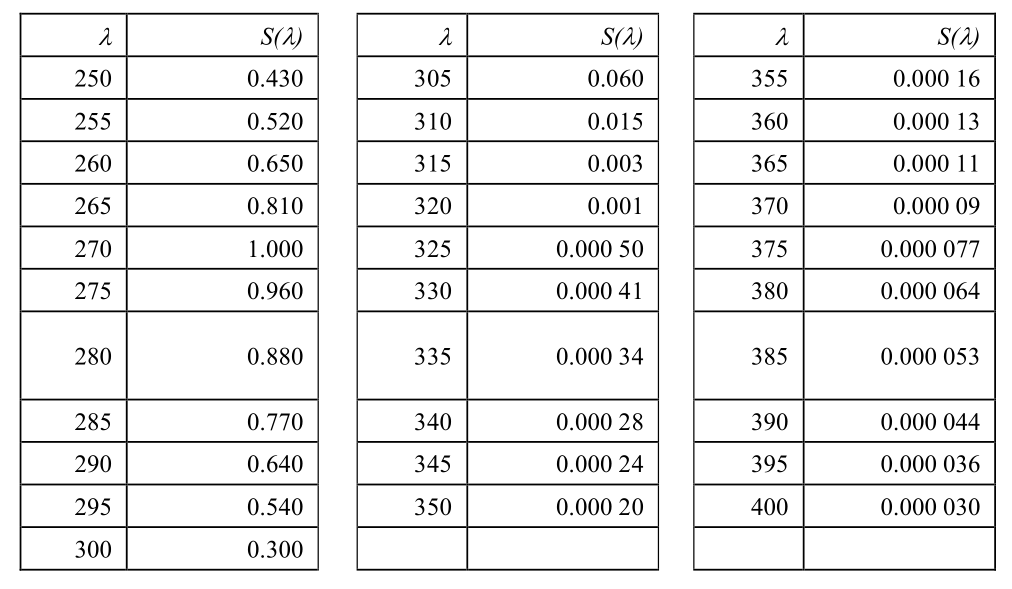

| 2.2.5. | For testing the ultraviolet (UV)-resistance of light transmitting components made of plastic material against UV radiation of LED modules inside the headlamp: | a0c0 | ||

| 2.2.5.1. | One sample of each of the relevant material as being used in the headlamp or one headlamp sample containing these. Each material sample shall have the same appearance and surface treatment, if any, as intended for use in the headlamp to be approved; | a0c0 | ||

| 2.2.5.2. |

The UV-resistance testing of internal materials to light source radiation is not necessary if no LED modules other than low-UV-types as specified in Annex 10 of this Regulation are being applied or if provisions are taken, to shield the relevant headlamp components from UV radiation, e.g. by glass filters. |

a0c0 | ||

| 2.2.6. | One electronic light source control gear, if applicable. | a0c0 | ||

| 2.3. | The materials making up the lenses and coatings, if any, shall be accompanied by the test report of the characteristics of these materials and coatings if they have already been tested. | a0c0 | ||

|

|

|

a4c0 | ||

|

|

|

a4c0 | ||

|

|

|

a4c0 | ||

| 3. |

|

a0c0 | ||

| 3.1. | Headlamps submitted for approval shall bear the trade name or mark of the applicant. | a0c0 | ||

| 3.2. | They shall comprise, on the lens and on the main body[3], spaces of sufficient size for the approval mark and the additional symbols referred to in paragraph 4; these spaces shall be indicated on the drawings referred to in paragraph 2.2.1. above. | a0c0 | ||

|

|

|

a0c0 | ||

| 3.3. | Headlamps equipped with passing-beam designed to satisfy the requirements both of right-hand and of left-hand traffic shall bear markings indicating the two settings of the optical unit or LED module on the vehicle or of the filament lamp on the reflector; these markings shall consist of the letters "R/D" for the position for right-hand traffic and the letters "L/G" for the position for left-hand traffic. | a0c0 | ||

| 3.4. | In the case of lamps with LED module(s), the lamp shall bear the marking of the rated voltage and rated wattage and the light source module specific identification code. | a0c0 | ||

| 3.5. | LED module(s) submitted along with the approval of the lamp: | a1c0 | ||

| 3.5.1. | Shall bear the trade name or mark of the applicant. This marking shall be clearly legible and indelible; | a1c0 | ||

| 3.5.2. | Shall bear the specific identification code of the module. This marking shall be clearly legible and indelible. | a1c0 | ||

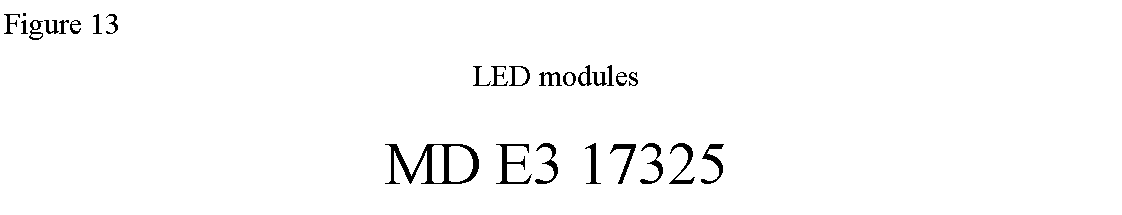

| ... | This specific identification code shall comprise the starting letters "MD" for "MODULE" followed by the approval marking without the circle as prescribed in paragraph 4.2.1. below and in the case several non-identical light source modules are used, followed by additional symbols or characters. This specific identification code shall be shown in the drawings mentioned in paragraph 2.2.1. above. The approval marking does not have to be the same as the one on the lamp in which the module is used, but both markings shall be from the same applicant. | a1c0 | ||

|

|

|

a1c0 | ||

| 3.6. | If an electronic light source control gear which is not part of a LED module is used to operate a LED module(s), it shall be marked with its specific identification code(s), the rated input voltage and wattage. | a0c0 | ||

| 4. |

|

a0c0 | ||

| 4.1. | General | a0c0 | ||

| 4.1.1. | If all the samples of a type of headlamp submitted pursuant to paragraph 2. above satisfy the provisions of this Regulation, approval shall be granted. | a0c0 | ||

| 4.1.2. | Where grouped, combined or reciprocally incorporated lamps satisfy the requirements of more than one Regulation, a single international approval mark may be affixed provided that each of the grouped, combined or reciprocally incorporated lamps satisfies the provisions applicable to it. | a0c0 | ||

| 4.1.3. | An approval number shall be assigned to each type approved. Its first two digits shall indicate the series of amendments incorporating the most recent major technical amendments made to the Regulation at the time of issue of the approval. The same Contracting Party may not assign the same number to another type of headlamp covered by this Regulation. | a0c0 | ||

| 4.1.4. |

Notice of approval or of extension or refusal or withdrawal of approval or production definitely discontinued of a type of headlamp pursuant to this Regulation shall be communicated to the Parties to the 1958 Agreement applying this Regulation, by means of a form conforming to the model in Annex 1 to this Regulation, with the indications according to paragraph 2.2.1.1. |

a0c0 | ||

| 4.1.4.1. | If the headlamp is equipped with an adjustable reflector and if this headlamp is to be used only in mounting positions according to the indications in paragraph 2.2.1.1. the applicant shall be obliged by the Type Approval Authority to inform the user in a proper way about the correct mounting position(s). | a0c0 | ||

| 4.1.5. | In addition to the mark prescribed in paragraph 3.1., an approval mark as described in paragraphs 4.2. and 4.3. below shall be affixed in the spaces referred to in paragraph 3.2. above to every headlamp conforming to a type approved under this Regulation. | a0c0 | ||

| 4.2. | Composition of the approval mark | a0c0 | ||

| ... | The approval mark shall consist of: | a0c0 | ||

| 4.2.1. | An international approval mark, comprising: | a0c0 | ||

| 4.2.1.1. | A circle surrounding the letter "E" followed by the distinguishing number of the country which has granted approval[4]; | a0c0 | ||

|

|

|

a0c0 | ||

| 4.2.1.2. | The approval number prescribed in paragraph 4.1.3. above; | a0c0 | ||

| 4.2.2. | The following additional symbol (or symbols): | a0c0 | ||

| 4.2.2.1. | On headlamps meeting left-hand traffic requirements only, a horizontal arrow pointing to the right of an observer facing the headlamp, i.e. to the side of the road on which the traffic moves; | a0c0 | ||

| 4.2.2.2. | On headlamps designed to meet the requirements of both traffic systems by means of an appropriate adjustment of the setting of the optical unit or the filament lamp or LED module(s), a horizontal arrow with a head on each end, the heads pointing respectively to the left and to the right; | a0c0 | ||

| 4.2.2.3. | On headlamps meeting the requirements of this Regulation in respect of the passing-beam only, the letters "C" for Class A headlamp or "HC" for Class B headlamp; | a0c0 | ||

| 4.2.2.4. | On headlamps meeting the requirements of this Regulation in respect of the driving-beam only, the letters "R" for Class A headlamp or "HR" for Class B headlamp; | a0c0 | ||

| 4.2.2.5. | On headlamps meeting the requirements of this Regulation in respect of both the passing-beam and the driving-beam, the letters "CR" for Class A headlamp or "HCR" for Class B headlamp; | a0c0 | ||

| 4.2.2.6. | On headlamps incorporating a lens of plastic material, the group of letters "PL" to be affixed near the symbols prescribed in paragraphs 4.2.2.3. to 4.2.2.5. above; | a0c0 | ||

| 4.2.2.7. | On headlamps meeting the requirements of this Regulation in respect of the driving-beam, an indication of the maximum luminous intensity expressed by a reference mark, as defined in paragraph 6.3.4. below, placed near the circle surrounding the letter "E"; | a0c0 | ||

| ... | In the case of grouped or reciprocally incorporated driving-beam headlamps, indication of the maximum luminous intensity of the driving-beams as a whole shall be expressed as above. | a0c0 | ||

| 4.2.3. | In every case the relevant operating mode used during the test procedure according to paragraph 1.1.1.1. of Annex 4 and the permitted voltage(s) according to paragraph 1.1.1.2. of Annex 4 shall be stipulated on the approval forms and on the communication forms transmitted to the countries which are Contracting Parties to the Agreement and which apply this Regulation. | a0c0 | ||

| ... | In the corresponding cases the device shall be marked as follows: | a0c0 | ||

| 4.2.3.1. | On headlamps meeting the requirements of this Regulation which are so designed that the filament or LED module(s) producing the principal passing-beam shall not be lit simultaneously with that of any other lighting function with which it may be reciprocally incorporated: an oblique stroke (/) shall be placed behind the symbol indicating the headlamp producing the passing-beam in the approval mark. | a0c0 | ||

| 4.2.3.2. | On headlamps equipped with filament lamps and meeting the requirements of Annex 4 to this Regulation only when supplied with a voltage of 6 V or 12 V, a symbol consisting of the number 24 crossed out by an oblique cross (x), shall be placed near the filament lamp holder. | a0c0 | ||

| 4.2.4. | The two digits of the approval number which indicate the series of amendments incorporating the most recent major technical amendments made to the Regulation at the time of issue of the approval and, if necessary, the required arrow may be marked close to the above additional symbols. | a0c0 | ||

| 4.2.5. | The marks and symbols referred to in paragraphs 4.2.1. to 4.2.3. above shall be clearly legible and be indelible. They may be placed on an inner or outer part (transparent or not) of the headlamp, which cannot be separated from the transparent part of the headlamp emitting the light. In any case they shall be visible when the headlamp is fitted on the vehicle or when a movable part such as the hood is opened. | a0c0 | ||

| 4.3. | Arrangement of the approval mark | a0c0 | ||

| 4.3.1. | Independent lamps | a0c0 | ||

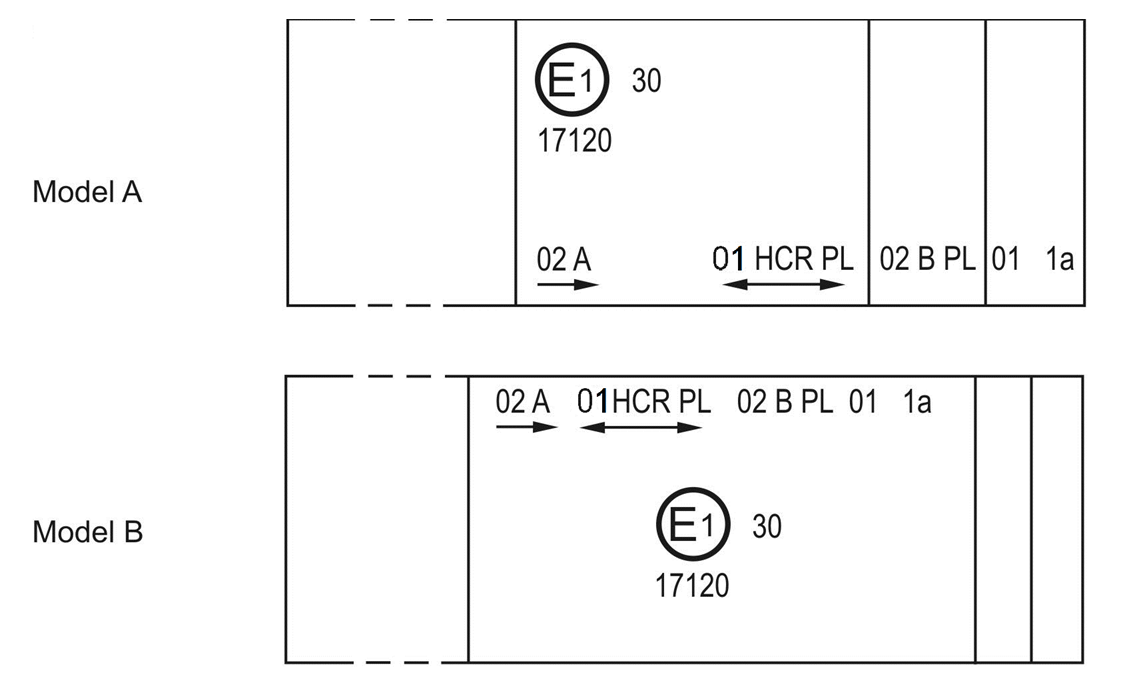

| ... | Figures 1 to 10 of Annex 2 to this Regulation give examples of arrangements of the approval mark with the above-mentioned additional symbols. | a0c0 | ||

| 4.3.2. | Grouped, combined or reciprocally incorporated lamps | a0c0 | ||

| 4.3.2.1. | Where grouped, combined or reciprocally incorporated lamps have been found to comply with the requirements of several Regulations, a single international approval mark may be affixed, consisting of a circle surrounding the letter "E" followed by the distinguishing number of the country which has granted the approval, and an approval number. This approval mark may be located anywhere on the grouped, combined or reciprocally incorporated lamps, provided that: | a0c0 | ||

| 4.3.2.1.1. | It is visible as per paragraph 4.2.5.; | a0c0 | ||

| 4.3.2.1.2. | No part of the grouped, combined or reciprocally incorporated lamps that transmits light can be removed without at the same time removing the approval mark. | a0c0 | ||

| 4.3.2.2. | The identification symbol for each lamp appropriate to each Regulation under which approval has been granted, together with the corresponding series of amendments incorporating the most recent major technical amendments to the Regulation at the time of issue of the approval, and if necessary, the required arrow shall be marked: | a0c0 | ||

| 4.3.2.2.1. | Either on the appropriate light-emitting surface, | a0c0 | ||

| 4.3.2.2.2. | Or in a group, in such a way that each of the grouped, combined or reciprocally incorporated lamps may be clearly identified (see four possible examples in Annex 2). | a0c0 | ||

| 4.3.2.3. | The size of the components of a single approval mark shall not be less than the minimum size required for the smallest of the individual marks by the Regulation under which approval has been granted. | a0c0 | ||

| 4.3.2.4. | An approval number shall be assigned to each type approved. The same Contracting Party may not assign the same number to another type of grouped, combined or reciprocally incorporated lamps covered by this Regulation. | a0c0 | ||

| 4.3.2.5. | Figure 11 of Annex 2 to this Regulation gives examples of arrangements of approval marks for grouped, combined or reciprocally incorporated lamps with all the above-mentioned additional symbols. | a0c0 | ||

| 4.3.3. | Lamps, the lens of which are used for different types of headlamps and which may be reciprocally incorporated or grouped with other lamps | a0c0 | ||

| ... | The provisions laid down in paragraph 4.3.2. above are applicable. | a0c0 | ||

| 4.3.3.1. | In addition, where the same lens is used, the latter may bear the different approval marks relating to the different types of headlamps or units of lamps, provided that the main body of the headlamp, even if it cannot be separated from the lens, also comprises the space described in paragraph 3.2. above and bears the approval marks of the actual functions. | a0c0 | ||

| ... | If different types of headlamps comprise the same main body, the latter may bear the different approval marks. | a0c0 | ||

| 4.3.3.2. | Figure 12 of Annex 2 to this Regulation gives examples of arrangements of approval marks relating to the above case. | a0c0 | ||

| B. |

|

a0c0 | ||

|

|

|

a0c0 | ||

| 5. |

|

a0c0 | ||

| ... |

|

a4c0 | ||

| 5.1. | Each sample shall conform to the specifications set forth in paragraphs 6. to 8. below. | a0c0 | ||

| 5.2. | Headlamps shall be so made as to retain their prescribed photometric characteristics and to remain in good working order when in normal use, in spite of the vibrations to which they may be subjected. | a0c0 | ||

| 5.2.1. | Headlamps shall be fitted with a device enabling them to be so adjusted on the vehicles as to comply with the rules applicable to them. Such a device need not be fitted on units in which the reflector and the diffusing lens cannot be separated, provided the use of such units is confined to vehicles on which the headlamp setting can be adjusted by other means. | a0c0 | ||

| ... | Where a headlamp providing a principal passing-beam and a headlamp providing a driving-beam, each equipped with its own filament lamp or LED module(s), the adjusting device shall enable the principal passing-beam and the driving-beam to be adjusted individually. | a0c0 | ||

| 5.2.2. | However, these provisions shall not apply to headlamp assemblies whose reflectors are indivisible. For this type of assembly the requirements of paragraph 6.3. of this Regulation apply. | a0c0 | ||

| 5.3. | The headlamp shall be equipped with: | a0c0 | ||

| 5.3.1. |

|

a5c0 | ||

| 5.3.1.1. | The design of the device shall be such that the filament lamp can be fixed in no other position but the correct one[6]; | a0c0 | ||

|

|

|

a0c0 | ||

| 5.3.1.2. | The filament lamp holder shall conform to the characteristics given in IEC Publication 60061. The holder data sheet relevant to the category of filament lamp used, applies. | a0c0 | ||

|

|

|

a1c0 | ||

| 5.3.2. | And/or LED module(s): | a1c0 | ||

| 5.3.2.1. |

Electronic light source control gear(s) |

a1c0 | ||

| 5.3.2.2. |

The headlamp, if equipped with LED modules, and the LED module(s) themselves shall comply with the relevant requirements specified in Annex 10 to this Regulation. The compliance with the requirements shall be tested. |

a0c0 | ||

| 5.3.2.3. | The total objective luminous flux of all LED modules producing the principal passing-beam and measured as described in paragraph 5. of Annex 10 shall be equal or greater than 1,000 lumens. | a0c0 | ||

| 5.3.2.4. | In the case of a replaceable LED module the removal and replacement of this LED module, as described in Annex 10, paragraph 1.4.1. shall be demonstrated to the satisfaction of the Technical Service. | a0c0 | ||

| 5.4. | Headlamps designed to satisfy the requirements both of right hand and of left hand traffic may be adapted for traffic on a given side of the road either by an appropriate initial setting when fitted on the vehicle or by selective setting by the user. Such initial or selective setting may consist, for example, of fixing either the optical unit at a given angle on the vehicle or the filament lamp or LED module(s) producing the principal passing-beam at a given angle/position in relation to the optical unit. In all cases, only two different and clearly distinct settings, one for right hand and one for left-hand traffic, shall be possible, and the design shall preclude inadvertent shifting from one setting to the other or setting in an intermediate position. Where two different setting positions are provided for the filament lamp or LED module(s) producing the principal passing-beam, the components for attaching the filament lamp or LED module(s) producing the principal passing-beam to the reflector must be so designed and made that, in each of its two settings, this filament lamp or LED module(s) will be held in position with the precision required for headlamps designed for traffic on only one side of the road. Conformity with the requirements of this paragraph shall be verified by visual inspection and, where necessary, by a test fitting. | a0c0 | ||

| 5.5. | Complementary tests shall be done according to the requirements of Annex 4 to ensure that in use there is no excessive change in photometric performance. | a0c0 | ||

| 5.6. | Light transmitting components made of plastic material shall be tested according to the requirements of Annex 6. | a0c0 | ||

| 5.7. | On headlamps designed to provide alternately a driving-beam and a passing-beam, or a passing-beam and/or a driving-beam designed to become bend lighting, any mechanical, electromechanical or other device incorporated in the headlamp for these purposes shall be so constructed that: | a0c0 | ||

| 5.7.1. | The device is robust enough to withstand 50,000 operations under normal conditions of use. In order to verify compliance with this requirement, the Technical Service responsible for approval tests may: | a0c0 | ||

| ... | (a)Require the applicant to supply the equipment necessary to perform the test; | a0c0 | ||

| ... | (b)Forego the test if the headlamp presented by the applicant is accompanied by a test report, issued by a Technical Service responsible for approval tests for headlamps of the same construction (assembly), confirming compliance with this requirement. | a0c0 | ||

| 5.7.2. |

In the case of failure, the luminous intensity above the line H-H shall not exceed the values of a passing-beam according to paragraph 6.2.4.; in addition, on headlamps designed to provide a passing and/or a driving-beam to become a bend lighting, a minimum luminous intensity of at least 2,500 cd. shall be fulfilled in test point 25 V (VV line, 1.72D). |

a0c0 | ||

| ... | When performing the tests to verify compliance with these requirements, the Technical Service responsible for approval tests shall refer to the instructions supplied by the applicant. | a0c0 | ||

| 5.7.3. | Either the principal passing-beam or the driving-beam shall always be obtained without any possibility of the mechanism stopping in between two positions; | a0c0 | ||

| 5.7.4. | The user cannot, with ordinary tools, change the shape or position of the moving parts. | a0c0 | ||

| 5.8. | Illumination configuration for different traffic conditions | a0c0 | ||

| 5.8.1. | In the case of headlamps designed to meet the requirements of traffic moving on one side of the road (either right or left) only, appropriate measures shall be taken to prevent discomfort to road-users in a country where traffic moves on the side of the road opposite to that of the country for which the headlamp was designed[7]. Such measures may be: | a0c0 | ||

| ... | (a)Occulting a part of the outer headlamp lens area; | a0c0 | ||

| ... | (b)Downward movement of the beam. Horizontal movement is allowed; | a0c0 | ||

| ... | (c)Any other measure to remove or reduce the asymmetrical part of the beam. | a0c0 | ||

|

|

|

a0c0 | ||

| 5.8.2. | Following the application of this (these) measure(s) the following requirements regarding the luminous intensity of the headlamp shall be met with the adjustment left unchanged compared to that for the original traffic direction: | a0c0 | ||

| 5.8.2.1. | Passing-beam designed for right-hand traffic and adapted to left-hand traffic: | a0c0 | ||

| ... | at 0.86D-1.72L at least 2,500 cd; | a0c0 | ||

| ... | at 0.57U-3.43R not more than 880 cd. | a0c0 | ||

| 5.8.2.2. | Passing-beam designed for left-hand traffic and adapted to right-hand traffic: | a0c0 | ||

| ... | at 0.86D-1.72R at least 2,500 cd; | a0c0 | ||

| ... | at 0.57U-3.43L not more than 880 cd. | a0c0 | ||

| 5.9. |

In case of a passing-beam headlamp incorporating a light source or LED module(s) producing the principal passing-beam and having a total objective luminous flux which exceeds 2,000 lumens, a reference shall be made in item 9. of the communication form in Annex 1. The objective luminous flux of LED modules shall be measured as described in paragraph 5. of Annex 10. |

a0c0 | ||

| 5.10. |

The definitions in paragraphs 2.7.1.1.3. and 2.7.1.1.7. in Regulation No. 48 allow the use of LED modules, which may contain holders for other light sources. Notwithstanding this provision a mixture of LED (s) and other light sources for the principal dipped beam or the contributor to the bend lighting or each driving-beam, as specified by this Regulation is not allowed. |

a0c0 | ||

| 5.11. | A LED module shall be: | a0c0 | ||

| ... | (a)Only removable from its device with the use of tools, unless it is stated in the communication sheet that the LED module is non-replaceable, and | a0c0 | ||

| ... | (b)So designed that regardless of the use of tool(s), it is not mechanically interchangeable with any replaceable approved light source. | a0c0 | ||

|

|

|

a7c0 | ||

| 6. |

|

a0c0 | ||

| 6.1. | General provisions | a0c0 | ||

| 6.1.1. | Headlamps shall be so made that they give adequate illumination without dazzle when emitting the passing-beam, and good illumination when emitting the driving-beam. Bend lighting may be produced by activating one additional filament light source or one or more LED module(s) being part of the passing-beam headlamp. | a0c0 | ||

| 6.1.2. |

The luminous intensity produced by the headlamp shall be measured at 25 m distance by means of a photoelectric cell having a useful area comprised within a square of 65 mm side. The point HV is the centre-point of the coordinate system with a vertical polar axis. Line h is the horizontal through HV (see Annex 3 to this Regulation). |

a0c0 | ||

| 6.1.3. |

Apart from LED module(s), the headlamps shall be checked by means of an uncoloured standard (étalon) filament lamp designed for a rated voltage of 12 V. |

a0c0 | ||

| 6.1.3.1. |

During the checking of the headlamp, the voltage at the terminals of the filament lamp shall be regulated as to obtain the reference luminous flux at 13.2 V as indicated for each filament lamp at the relevant data sheet of Regulation No. 37. |

a0c0 | ||

| ... |

However, if a filament lamp of category H9 or H9B is used for the principal passing-beam, the applicant may choose the reference luminous flux at 12.2 V or 13.2 V as indicated in the relevant data sheet of Regulation No. 37 and a reference stating which voltage was chosen for type approval shall be made in item 9 in the communication form of Annex 1. |

a0c0 | ||

| 6.1.3.2. |

In order to protect the standard (étalon) filament lamp during the process of photometric measurement it is permissible to carry out the measurements at a luminous flux that differs from the reference luminous flux at 13.2 V. If the Technical Service chooses to carry out measurements in such a manner, the luminous intensity shall be corrected by multiplying the measured value by the individual factor F lamp of the standard (étalon) filament lamp in order to verify the compliance with the photometric requirements where: |

a0c0 | ||

| ... | F lamp = Φ reference / Φ test | a0c0 | ||

| ... |

Φ reference is the reference luminous flux at 13,2 V as specified in the relevant data sheet of Regulation No. 37 |

a0c0 | ||

| ... | Φ test is the actual luminous flux used for the measurement. | a0c0 | ||

| ... |

However, where the reference luminous flux of 12.2 V as specified in the data sheet for the category H9 or H9B is chosen, this procedure is not permitted. |

a0c0 | ||

| 6.1.3.3. |

The headlamp shall be considered acceptable if it meets the requirements of paragraph 6. with at least one standard (étalon) filament lamp, which may be submitted with the headlamp. |

a0c0 | ||

| 6.1.4. |

LED module(s) shall be measured at 6.3 V, 13.2 V or 28.0 V respectively, if not otherwise specified within this Regulation. LED module(s) operated by an electronic light source control gear, shall be measured as specified by the applicant. |

a0c0 | ||

| 6.1.5. | In the case of headlamps equipped with LED module(s) and filament lamps, the part of the headlamp with filament lamp(s) shall be tested according to paragraph 6.1.3. and the part of the headlamp with LED module(s) shall be evaluated according to the provisions of paragraph 6.1.4. and then added to the previous result obtained from the filament lamp(s) tested. | a0c0 | ||

| 6.2. | Provisions concerning passing-beams | a0c0 | ||

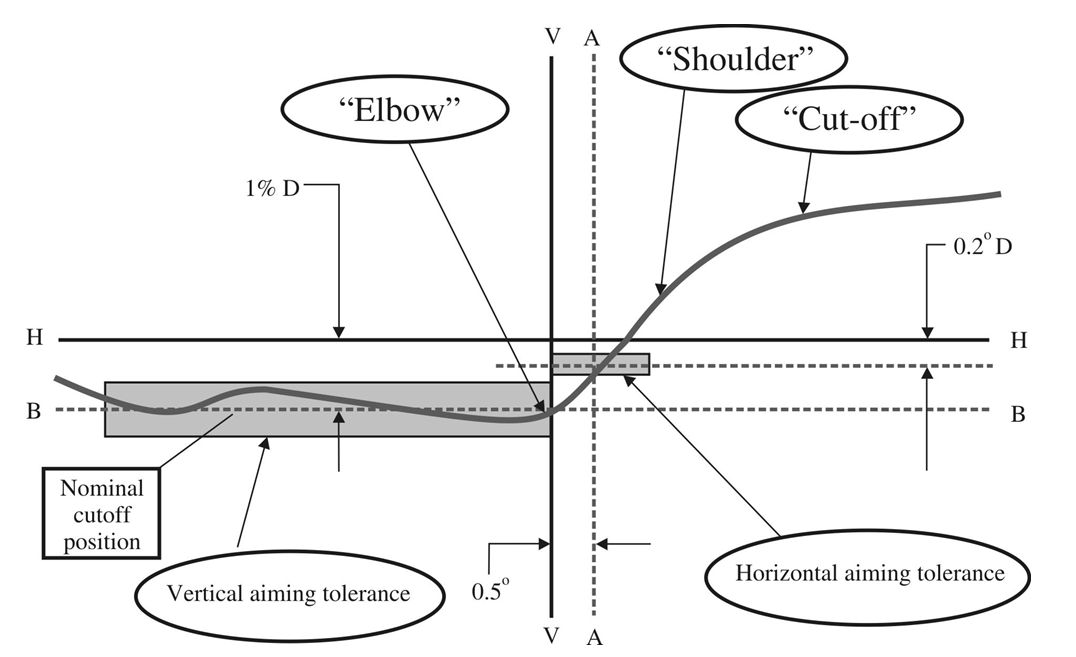

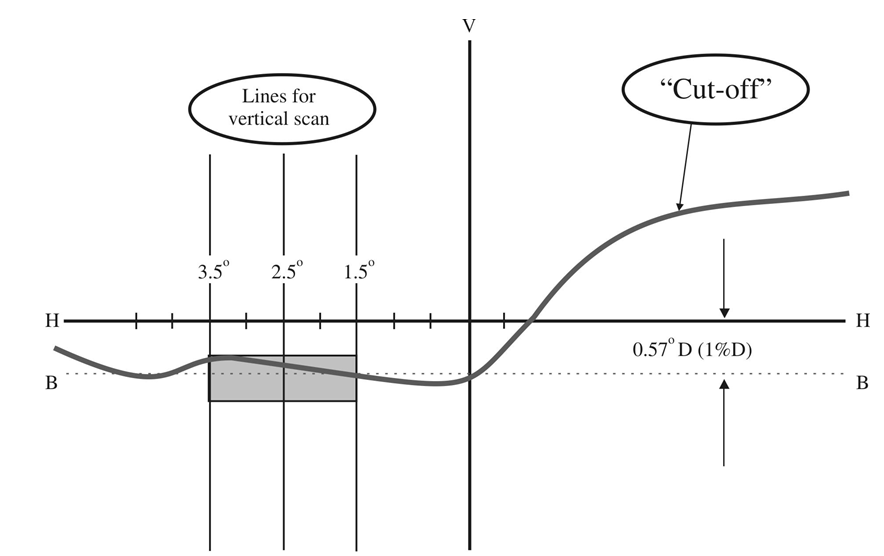

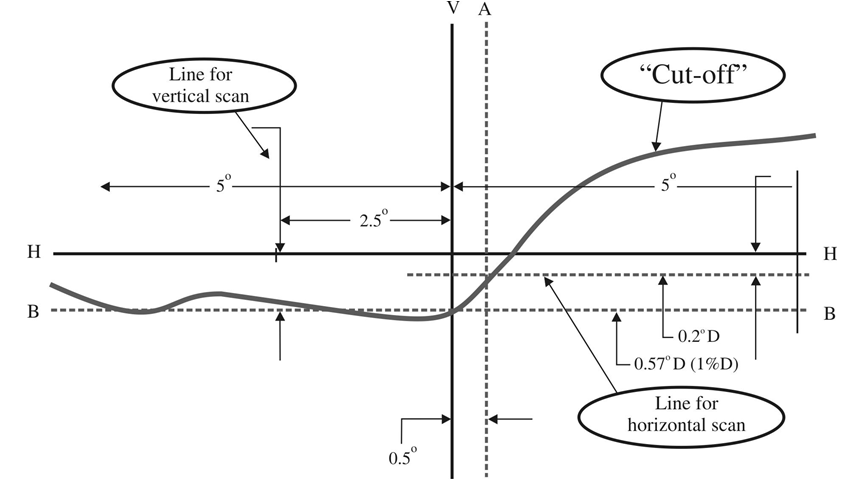

| 6.2.1. | The luminous intensity distribution of the principal passing-beam headlamp shall incorporate a "cut-off" (see Figure 1), which enables the headlamp to be adjusted correctly for the photometric measurements and for the aiming on the vehicle. | a0c0 | ||

| ... | The "cut-off" shall provide: | a0c0 | ||

| ... | (a)For right hand traffic beams: | a0c0 | ||

| ... | (i)A straight "horizontal part" towards the left; | a0c0 | ||

| ... | (ii)A raised "elbow - shoulder" part towards the right. | a0c0 | ||

| ... | (b)For left hand traffic beams: | a0c0 | ||

| ... | (i)A straight "horizontal part" towards the right; | a0c0 | ||

| ... | (ii)A raised "elbow - shoulder" part towards the left. | a0c0 | ||

| ... | In each case the "elbow-shoulder" part shall have a sharp edge. | a0c0 | ||

| 6.2.2. |

The headlamp shall be visually aimed by means of the "cut-off" (see Figure 1) as follows. The aiming shall be carried out using a flat vertical screen set up at a distance of 10 m or 25 m (as indicated in item 9 of Annex 1) forward of the headlamp and at right angles to the H-V axis as shown in Annex 3 to this Regulation. The screen shall be sufficiently wide to allow examination and adjustment of the "cut-off" of the passing-beam over at least 5° on either side of the V-V line. |

a0c0 | ||

| 6.2.2.1. |

For vertical adjustment: the horizontal part of the "cut-off" is moved upward from below line B and adjusted to its nominal position one per cent (0.57 degrees) below the H-H line; |

a0c0 | ||

| ... | Figure 1 | a0c0 | ||

| ... |

|

a0c0 | ||

| ... | Note: The scales are different for vertical and horizontal lines. | a0c0 | ||

| 6.2.2.2. |

For horizontal adjustment: the "elbow - shoulder" part of the "cut-off" shall be moved: |

a0c0 | ||

| ... | For right hand traffic from right to left and shall be horizontally positioned after its movement so that: | a0c0 | ||

| ... |

(a)Above the line 0.2° D its "shoulder" shall not exceed the line A to the left; |

a0c0 | ||

| ... |

(b)The line 0.2° D or below its "shoulder" should cross the line A; and |

a0c0 | ||

| ... | (c)The kink of the "elbow" is basically located within +/-0.5 degrees to the left or right of the V-V line; | a0c0 | ||

| ... | or | a0c0 | ||

| ... | For left hand traffic from left to right and shall be horizontally positioned after its movement so that: | a0c0 | ||

| ... | (a)Above the line 0.2 D its "shoulder" shall not exceed the line A to the right; | a0c0 | ||

| ... |

(b)On the line 0.2° or below its "shoulder" cross the line A; and |

a0c0 | ||

| ... | (c)The kink of the "elbow" should be primarily on the V-V line; | a0c0 | ||

| 6.2.2.3. | Where a headlamp so aimed does not meet the requirements set out in paragraphs 6.2.4. to 6.2.6. and 6.3., its alignment may be changed, provided that the axis of the beam is not displaced: | a0c0 | ||

| ... | Horizontally from line A by more than: | a0c0 | ||

| ... |

(a) 0.5° to the left or 0.75° to the right, for right hand traffic; or |

a0c0 | ||

| ... |

(b)0.5° to the right or 0.75° to the left, for left hand traffic; and |

a0c0 | ||

| ... |

Vertically not more than 0.25° up or down from line B. |

a0c0 | ||

| 6.2.2.4. | If, however, vertical adjustment cannot be performed repeatedly to the required position within the tolerances described in paragraph 6.2.2.3. above, the instrumental method of Annex 9, paragraphs 2. and 3. shall be applied to test compliance with the required minimum quality of the "cut-off" and to perform the vertical and horizontal adjustment of the beam. | a0c0 | ||

| 6.2.3. | When so aimed, the headlamp, if its approval is sought solely for provision of a passing-beam[8], need comply only with the requirements set out in paragraphs 6.2.4. to 6.2.6. below; if it is intended to provide both a passing-beam and a driving-beam, it shall comply with the requirements set out in paragraphs 6.2.4. to 6.2.6. and 6.3. | a0c0 | ||

|

|

|

a0c0 | ||

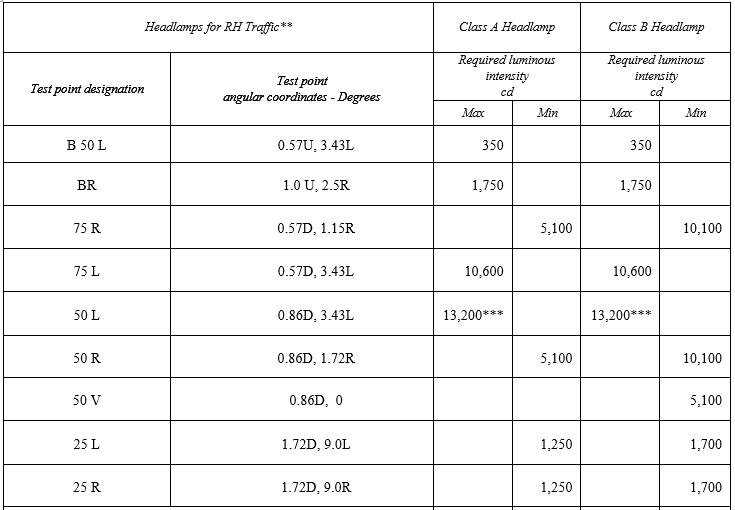

| 6.2.4. | The passing-beam shall meet the luminous intensities at the test points referred to in the tables below and in Annex 3 Figure B (or mirrored about the VV line for left-hand traffic): | a0c0 | ||

| ... |

|

a0c0 | ||

| ... |

|

a0c0 | ||

| ... |

|

a0c0 | ||

| 6.2.5. | There shall be no lateral variations detrimental to good visibility in any of the zones I, II, III and IV. | a0c0 | ||

| 6.2.6. | Headlamps designed to meet the requirements of both right-hand and left-hand traffic must, in each of the two setting positions of the optical unit or LED module(s) producing the principal passing-beam or of the filament lamp, meet the requirements set forth above for the corresponding direction of traffic. | a0c0 | ||

| 6.2.7. |

The requirements in paragraph 6.2.4. above shall also apply to headlamps designed to provide bend lighting and/or that include the additional light source or LED module(s) referred to in paragraph 6.2.8.2. In the case of a headlamp designed to provide bend lighting its alignment may be changed, provided that the axis of the beam is not displaced vertically by more than 0.2°. |

a0c0 | ||

| 6.2.7.1. | If bend lighting is obtained by: | a0c0 | ||

| 6.2.7.1.1. | Swivelling the passing-beam or moving horizontally the kink of the elbow of the cut-off, the measurements shall be carried out after the complete headlamp assembly has been reaimed horizontally, e.g. by means of a goniometer; | a0c0 | ||

| 6.2.7.1.2. | Moving one or more optical parts of the headlamp without moving horizontally the kink of the elbow of the cut-off, measurements shall be carried out with these parts being in their extreme operating position; | a0c0 | ||

| 6.2.7.1.3. | Means of one additional filament light source or one or more LED module(s) without moving horizontally the kink of the elbow of the cut-off, measurements shall be carried out with this light source or LED module(s) activated. | a0c0 | ||

| 6.2.8. | Only one filament light source or one or more LED module(s) are permitted for the principal passing-beam. Additional light sources or LED modules are permitted only as follows (see Annex 10): | a0c0 | ||

| 6.2.8.1. | One additional light source according to Regulation No. 37 or one or more additional LED module(s) may be used inside the passing-beam headlamp to contribute to bend lighting; | a0c0 | ||

| 6.2.8.2. | One additional light source according to Regulation No. 37 and/or one or more LED module(s), inside the passing-beam headlamp, may be used for the purposes of generating infrared radiation. It/they shall only be activated at the same time as the principal light source or LED module(s). In the event that the principal light source or (one of) the principal LED module(s) fails, this additional light source and/or LED module(s) shall be automatically switched off; | a0c0 | ||

| 6.2.8.3. | In the event of failure of an additional filament light source or one or more additional LED module(s), the headlamp shall continue to fulfil the requirements of the passing-beam. | a0c0 | ||

| 6.3. | Provisions concerning driving-beams | a0c0 | ||

| 6.3.1. |

In the case of a headlamp designed to provide a driving-beam and a passing-beam, measurements of the luminous intensity of the driving-beam shall be taken with the same headlamp alignment as for measurements under paragraphs 6.2.4. to 6.2.6. above; in the case of a headlamp providing a driving-beam only, it shall be so adjusted that the area of maximum luminous intensity is centred on the point of intersection of lines H-H and V-V; such a headlamp need meet only the requirements referred to in paragraph 6.3. Where more than one light source is used to provide the driving-beam, the combined functions shall be used to determine the maximum value of the luminous intensity (IM). |

a0c0 | ||

| 6.3.2. | Irrespective of the type of light source (LED module(s) or filament light source(s)) used to produce the principal passing-beam, several light sources: | a0c0 | ||

| ... | (a)Either filament light sources listed in Regulation No. 37; or | a0c0 | ||

| ... | (b)LED module(s) may be used for each individual driving-beam. | a0c0 | ||

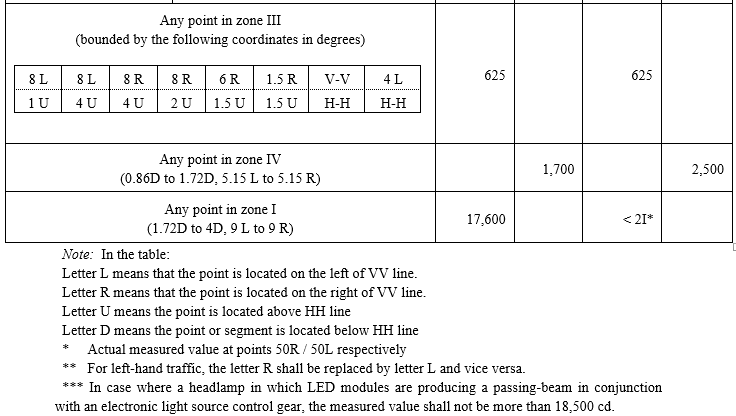

| 6.3.3. | Referring to Annex 3, Figure C and the table below, the luminous intensity distribution of the driving-beam shall meet the following requirements: | a0c0 | ||

| ... |

|

a0c0 | ||

| 6.3.3.1. |

The point of intersection (HV) of lines h h and v v shall be situated within the isolux 80 per cent of maximum luminous intensity (Imax) |

a0c0 | ||

| 6.3.3.2. | The maximum value (IM) shall in no circumstances exceed 215,000 cd. | a0c0 | ||

| 6.3.4. |

The reference mark (I'M) of the maximum luminous intensity, referred to in paragraph 6.3.3.2. above, shall be obtained by the ratio: |

a0c0 | ||

| ... | I'M = IM /4,300 | a0c0 | ||

| ... | This value shall be rounded off to the value 7.5 - 10 - 12.5 - 17.5 - 20 - 25 - 27.5 - 30 - 37.5 - 40 - 45 - 50. | a0c0 | ||

| 6.4. | In the case of headlamps with adjustable reflector the requirements of paragraphs 6.2. and 6.3. are applicable for each mounting position indicated according to paragraph 2.1.3. For verification the following procedure shall be used: | a0c0 | ||

| 6.4.1. | Each applied position is realized on the test goniometer with respect to a line joining the centre of the light source and point HV on a aiming screen. The adjustable reflector is then moved into such a position that the light pattern on the screen corresponds to the aiming prescriptions of paragraphs 6.2.1. to 6.2.2.3. and/or 6.3.1.; | a0c0 | ||

| 6.4.2. | With the reflector initially fixed according to paragraph 6.4.1., the headlamp must meet the relevant photometric requirements of paragraphs 6.2. and 6.3.; | a0c0 | ||

| 6.4.3. |

Additional tests are made after the reflector has been moved vertically ±2° or at least into the maximum position, if less than 2°, from its initial position by means of the headlamps adjusting device. Having re-aimed the headlamp as a whole (by means of the goniometer for example) in the corresponding opposite direction the light output in the following directions shall be controlled and lie within the required limits: |

a4c0 | ||

| ... |

Passing-beam: points |

a4c0 | ||

| ... | Driving-beam: IM and point HV (percentage of IM). | a4c0 | ||

| 6.4.4. | If the applicant has not indicated more than one mounting position, the procedure of paragraphs 6.4.1. to 6.4.3. shall be repeated for all other positions; | a0c0 | ||

| 6.4.5. |

If the applicant has not asked for special mounting positions, the headlamp shall be aimed for measurements of paragraphs 6.2. and 6.3. with the headlamps adjusting device in its mean position. The additional test of paragraph 6.4.3. shall be made with the reflector moved into its extreme positions (instead of ±2°) by means of the headlamps adjusting device. |

a0c0 | ||

| 7. |

|

a0c0 | ||

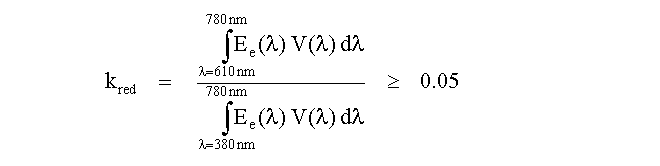

| 7.1. | The colour of the light emitted shall be white. | a0c0 | ||

| 8. |

|

a0c0 | ||

| ... | The discomfort caused by the passing-beam of headlamps shall be gauged[9]. | a0c0 | ||

|

|

|

a0c0 | ||

| C. |

|

a0c0 | ||

| 9. |

|

a0c0 | ||

| 9.1. | Every modification of the headlamp type shall be notified to the Type Approval Authority which approved the headlamp type. The said Authority may then either: | a0c0 | ||

| 9.1.1. | Consider that the modifications made are unlikely to have appreciable adverse effects and that in any event the headlamp still complies with the requirements; or | a0c0 | ||

| 9.1.2. | Require a further test report from the Technical Service responsible for conducting the tests. | a0c0 | ||

| 9.2. | Confirmation or refusal of approval, specifying the alterations, shall be communicated by the procedure specified in paragraph 4.1.4. above to the Parties to the Agreement which apply this Regulation. | a0c0 | ||

| 9.3. | The competent Authority issuing the extension of approval shall assign a series number to each communication form drawn up for such an extension and inform thereof the other Parties to the 1958 Agreement applying this Regulation by means of a communication form conforming to the model in Annex 1 to this Regulation. | a0c0 | ||

| 10. |

|

a0c0 | ||

| ... | The conformity of production procedures shall comply with those set out in the Agreement, Appendix 2 (E/ECE/324-E/ECE/TRANS/505/Rev.2) with the following requirements: | a0c0 | ||

| 10.1. |

The compliance with the requirements set forth in paragraphs 6. and 7. above shall be verified as follows: The minimum requirements for Conformity of Production (CoP) control procedures set forth in Annex 5 to this Regulation shall be complied with. The minimum requirements for sampling by an inspector set forth in Annex 7 to this Regulation shall be complied with. |

a4c0 | ||

| 10.2. |

|

a4c0 | ||

| 10.3. |

|

a4c0 | ||

| 10.4. |

|

a4c0 | ||

| 10.5. |

|

a4c0 | ||

| 10.6. |

|

a4c0 | ||

| 10.7. | The measuring points 1 to 8 from paragraph 6.2.4. of this Regulation are disregarded. | a0c0 | ||

| 11. |

|

a0c0 | ||

| 11.1. | The approval granted in respect of a type of headlamp pursuant to this Regulation may be withdrawn if the requirements are not complied with or if a headlamp bearing the approval mark does not conform to the type approved. | a0c0 | ||

| 11.2. | If a Contracting Party to the Agreement applying this Regulation withdraws an approval it has previously granted, it shall forthwith so notify the other Contracting Parties applying this Regulation by means of a communication form conforming to the model in Annex 1 to this Regulation. | a0c0 | ||

| 12. |

|

a0c0 | ||

| ... | If the holder of the approval completely ceases to manufacture a type of headlamp approved in accordance with this Regulation, he shall so inform the authority which granted the approval. Upon receiving the relevant communication, that authority shall inform thereof the other Parties to the 1958 Agreement applying this Regulation by means of a communication form conforming to the model in Annex 1 to this Regulation. | a0c0 | ||

| 13. |

|

a0c0 | ||

| ... | The Parties to the 1958 Agreement applying this Regulation shall communicate to the United Nations Secretariat the names and addresses of the Technical Services responsible for conducting approval tests and of the Type Approval Authorities which grant approval and to which forms certifying approval or extension or refusal or withdrawal of approval, or production definitively discontinued, issued in other countries, are to be sent. | a0c0 | ||

| 14. |

|

a0c0 | ||

|

|

|

a6c0 | ||

|

|

|

a6c0 | ||

|

|

|

a6c0 | ||

|

|

|

a6c0 | ||

|

|

|

a6c0 | ||

|

|

|

a6c0 | ||

|

|

|

a6c0 | ||

|

|

|

a6c0 | ||

|

|

|

a6c0 | ||

|

|

|

a6c0 | ||

| A1 |

|

a0c0 | ||

| A1 |

|

a0c0 | ||

| A1 | (Maximum format: A4 (210 x 297 mm)) | a0c0 | ||

| A1 |

|

a0c0 | ||

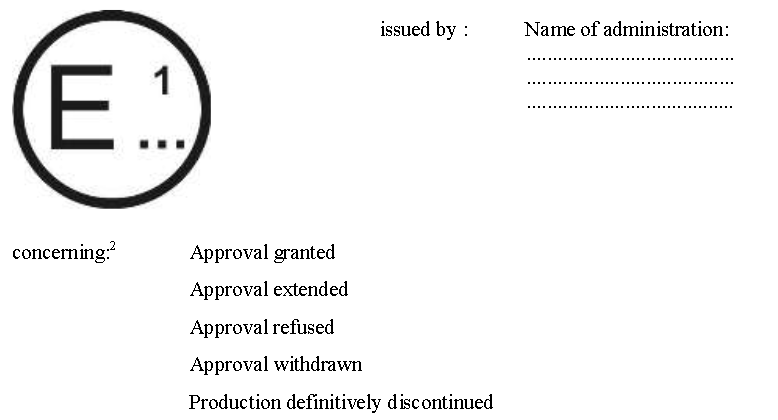

| A1 | of a type of headlamp pursuant to Regulation No. 112 | a0c0 | ||

| A1 |

|

a0c0 | ||

| A1 1. | Trade name or mark of the device: | a0c0 | ||

| A1 2. | Manufacturer's name for the type of device: | a0c0 | ||

| A1 3. | Manufacturer's name and address: | a0c0 | ||

| A1 4. | If applicable, name and address of manufacturer's representative: | a0c0 | ||

| A1 5. | Submitted for approval on: | a0c0 | ||

| A1 6. | Technical Service responsible for conducting approval tests: | a0c0 | ||

| A1 7. | Date of report issued by that Service: | a0c0 | ||

| A1 8. | Number of report issued by that Service: | a0c0 | ||

| A1 9. | Brief description: | a0c0 | ||

| A1 | Category as described by the relevant marking[3]: | a0c0 | ||

| A1 | Number and category(s) of filament lamp(s): | a0c0 | ||

| A1 | Reference luminous flux used for the principal passing-beam (lm): | a0c0 | ||

| A1 | Principal passing-beam operated at approximately (V): | a0c0 | ||

| A1 | Measures according to paragraph 5.8. of this Regulation: | a0c0 | ||

| A1 | Number and specific identification code(s) of LED module(s) and for each LED module a statement whether it is replaceable or not: yes/no[2] | a0c0 | ||

| A1 | Number and specific identification code(s) of electronic light source control gear(s) | a0c0 | ||

| A1 |

Total objective luminous flux as described in paragraph 5.9. exceeds 2,000 lumens: yes/no/does not apply[2] |

a0c0 | ||

| A1 | The adjustment of the cut-off has been determined at: 10 m/25 m/does not apply[2] | a0c0 | ||

| A1 | The determination of the minimum sharpness of the "cut-off" has been carried out at: 10 m/25 m/does not apply[2] | a0c0 | ||

| A1 10. | Approval mark position: | a0c0 | ||

| A1 11. | Reason(s) for extension of approval: | a0c0 | ||

| A1 12. | Approval granted/extended/refused//withdrawn2 | a0c0 | ||

| A1 13. | Place: | a0c0 | ||

| A1 14. | Date: | a0c0 | ||

| A1 15. | Signature: | a0c0 | ||

| A1 16. | The list of documents deposited with the Type Approval Authority which has granted approval is annexed to this communication and may be obtained on request. | a0c0 | ||

|

A1 |

|

a0c0 | ||

|

A1 |

|

a0c0 | ||

|

A1 |

|

a0c0 | ||

| A1 |

|

a0c0 | ||

| A2 |

|

a0c0 | ||

| A2 |

|

a0c0 | ||

| A2 |

|

a1c0 | ||

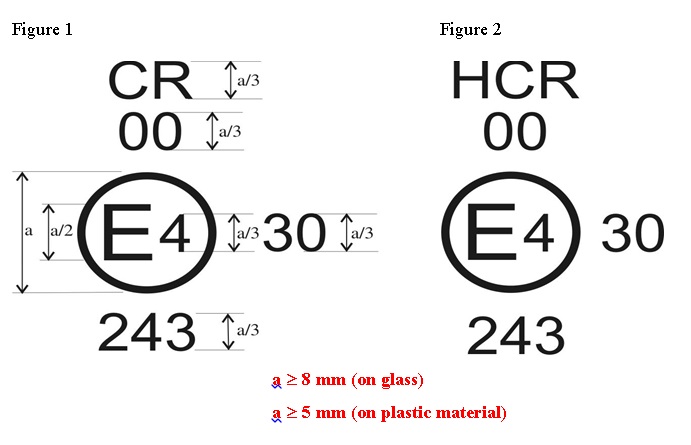

| A2 |

The headlamp bearing one of the above approval marks has been approved in the Netherlands (E4) pursuant to Regulation No. 112 under approval number 243, meeting the requirements of this Regulation, as amended by the 01 series of amendments. The passing-beam is designed for right-hand traffic only. The letters CR (Figure 1) indicate that it concerns a Class A passing and driving-beam and the letters HCR (Figure 2) indicate that it concerns a Class B passing and driving-beam. |

a0c0 | ||

| A2 | The figure 30 indicates that the maximum luminous intensity of the driving-beam is between 123,625 and 145,125 candelas. | a0c0 | ||

| A2 | Note: The approval number and additional symbols shall be placed close to the circle and either above or below the letter "E", or to the right or left of that letter. The digits of the approval number shall be on the same side of the letter "E" and face in the same direction. | a0c0 | ||

| A2 | The use of Roman numerals as approval numbers should be avoided so as to prevent any confusion with other symbols. | a0c0 | ||

| A2 |

|

a0c0 | ||

| A2 |

|

a0c0 | ||

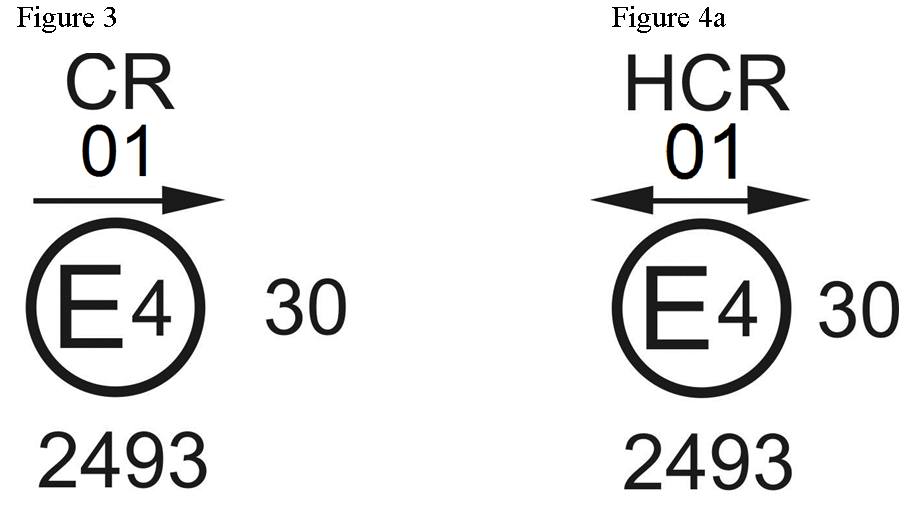

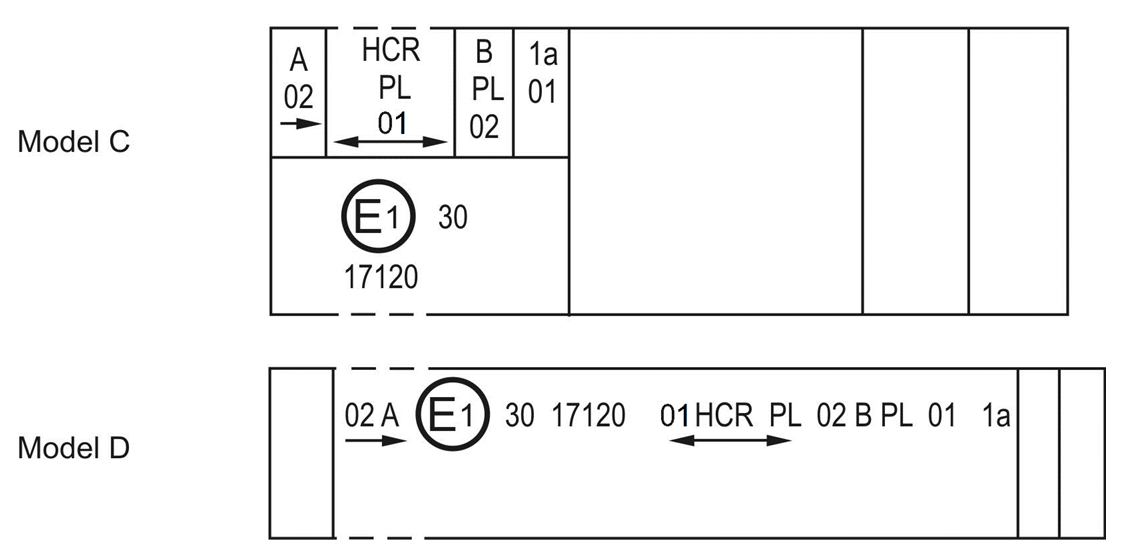

| A2 | The headlamp bearing the above approval mark meets the requirements of this Regulation in respect of both the passing-beam and the driving-beam and is designed: | a0c0 | ||

| A2 | Figure 3: Class A for left hand traffic only. | a0c0 | ||

| A2 | Figures 4a and 4b: Class B for both traffic systems by means of an appropriate adjustment of the setting of the optical unit or the filament lamp on the vehicle. | a0c0 | ||

| A2 |

|

a4c0 | ||

| A2 | The headlamp bearing the above approval mark is a headlamp incorporating a lens of plastic material meeting the requirements of this Regulation in respect of the passing-beam only and is designed: | a4c0 | ||

| A2 |

Figure 5: Class A for |

a4c0 | ||

| A2 |

Figure 6: Class B for |

a4c0 | ||

| A2 |

|

a4c0 | ||

| A2 | The headlamp bearing the above approval mark is a headlamp meeting the requirements of this Regulation: | a4c0 | ||

| A2 | Figure 7: Class B in respect of the passing-beam only and is designed for left-hand traffic only. | a4c0 | ||

| A2 | Figure 8: Class A in respect of the driving-beam only. | a4c0 | ||

| A2 |

|

a4c0 | ||

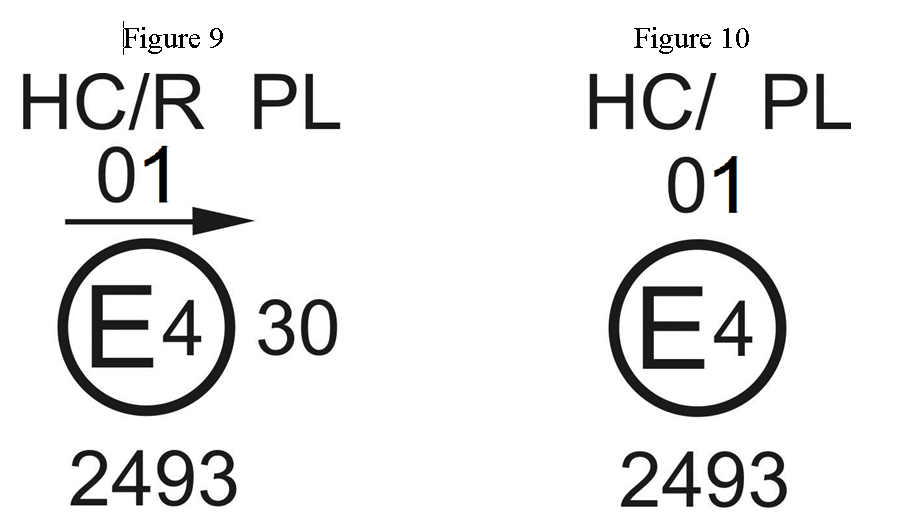

| A2 | Identification of a headlamp incorporating a lens of plastic material meeting the requirements of this Regulation: | a4c0 | ||

| A2 |

Figure 9: Class B in respect to both the passing-beam and driving-beam and designed for |

a4c0 | ||

| A2 | Figure 10: Class B in respect to the passing-beam only and designed for right-hand traffic only. | a4c0 | ||

| A2 | The passing-beam shall not be operated simultaneously with the driving-beam and/or another reciprocally incorporated headlamp. | a0c0 | ||

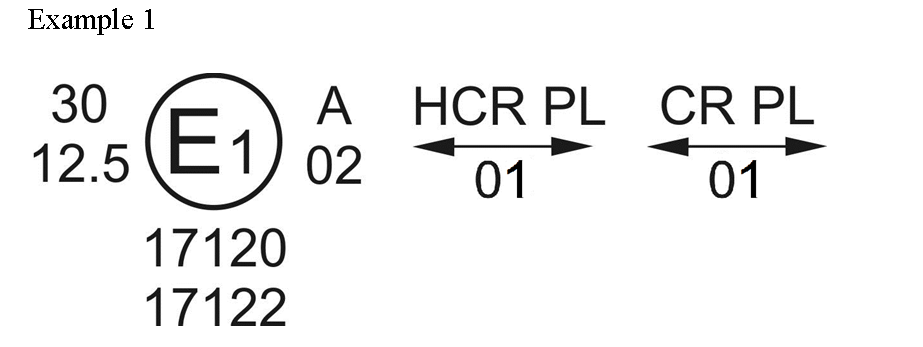

| A2 | Figure 11 | a0c0 | ||

| A2 | Simplified marking for grouped, combined or reciprocally incorporated lamps | a0c0 | ||

| A2 | (The vertical and horizontal lines schematize the shape of the light-signalling device. They are not part of the approval mark). | a0c0 | ||

| A2 |

|

a0c0 | ||

| A2 |

|

a0c0 | ||

| A2 | Note: The four examples above correspond to a lighting device bearing an approval mark comprising: | a0c0 | ||

| A2 |

A front position lamp approved in accordance with the 02 series of amendments to Regulation No. 7, |

a0c0 | ||

| A2 |

A headlamp, Class B, with a passing-beam designed for right- and left-hand traffic and a driving-beam with a maximum intensity comprised between 123,625 and 145,125 candelas (as indicated by the number 30), approved in accordance with the requirements of this Regulation, as amended by the 01 series of amendments and incorporating a lens of plastic material, |

a0c0 | ||

| A2 | A front fog lamp approved in accordance with the 02 series of amendments to Regulation No. 19 and incorporating a lens of plastic material, | a0c0 | ||

| A2 | A front direction indicator lamp of category 1a approved in accordance with the 01 series of amendments to Regulation No. 6. | a0c0 | ||

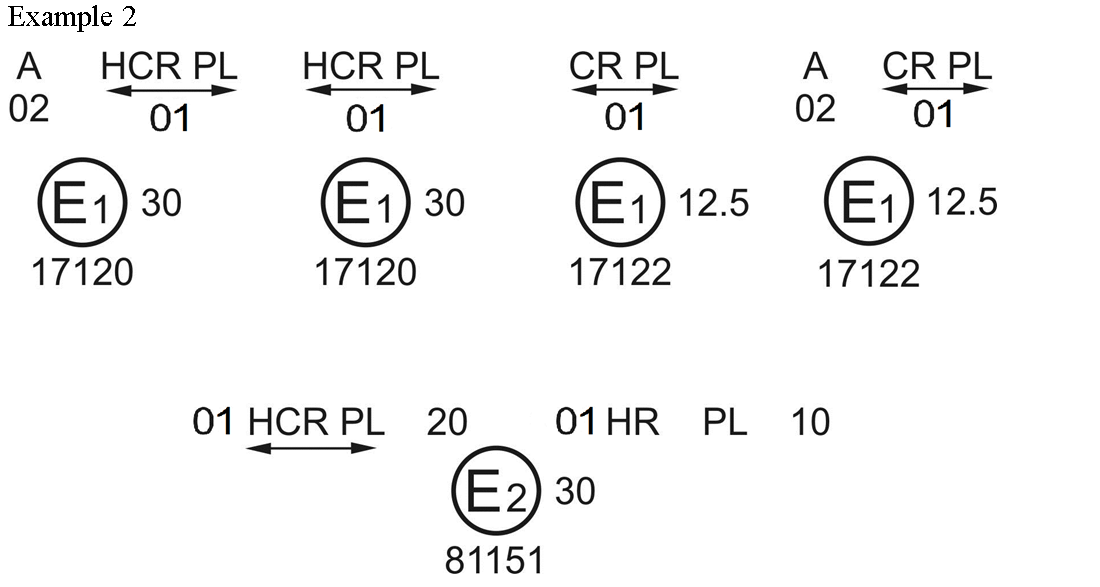

| A2 | Figure 12 | a0c0 | ||

| A2 | Lamp reciprocally incorporated with a headlamp | a0c0 | ||

| A2 |

|

a0c0 | ||

| A2 | The above example corresponds to the marking of a lens of plastic material intended to be used in different types of headlamps, namely: | a0c0 | ||

| A2 | Either | a0c0 | ||

| A2 | A headlamp, Class B, with a passing-beam designed for both traffic systems and a driving-beam with a maximum luminous intensity comprised between 123,625 and 145,125 candelas (as indicated by the number 30), approved in Germany (E1) in accordance with the requirements of this Regulation, as amended by the 01 series of amendments, | a0c0 | ||

| A2 | Which is reciprocally incorporated with | a0c0 | ||

| A2 | A front position lamp approved in accordance with the 02 series of amendments to Regulation No. 7; | a0c0 | ||

| A2 | or | a0c0 | ||

| A2 | A headlamp, Class A, with a passing-beam designed for both traffic systems and a driving-beam with a maximum luminous intensity comprised between 48,375 cd and 64,500 cd (as indicated by the number 12.5), approved in Germany (E1) in accordance with the requirements of this Regulation, as amended by the 01 series of amendments, | a0c0 | ||

| A2 | Which is reciprocally incorporated with: | a0c0 | ||

| A2 | The same front position lamp as above; | a0c0 | ||

| A2 | or | a0c0 | ||

| A2 | Even either of the above-mentioned headlamps approved as a single lamp. | a0c0 | ||

| A2 | The main body of the headlamp shall bear the only valid approval number, for instance: | a0c0 | ||

| A2 |

|

a0c0 | ||

| A2 |

The above example corresponds to the marking of a lens of plastic material used in a unit of two headlamps approved in France (E2) under approval number 81151, consisting of: |

a0c0 | ||

| A2 | A headlamp, Class B, emitting a passing-beam and a driving-beam with a maximum luminous intensity between x and y candelas, meeting the requirements of this Regulation, and | a0c0 | ||

| A2 | A headlamp, Class B, emitting a driving-beam designed for both traffic systems with a maximum luminous intensity between w and z candelas, meeting the requirements of this Regulation, the maximum luminous intensities of the driving-beams as a whole being comprised between 123,625 and 145,125 candelas. | a0c0 | ||

| A2 |

|

a0c0 | ||

| A2 |

The LED module bearing the light source module identification code shown above has been approved together with a headlamp initially approved in Italy (E3) under approval number 17325. |

a0c0 | ||

| A3 |

|

a0c0 | ||

| A3 |

|

a0c0 | ||

| A3 |

|

a0c0 | ||

| A3 | Figure B | a0c0 | ||

| A3 | Passing-beam for right-hand traffic | a0c0 | ||

| A3 |

|

a4c0 | ||

| A3 | Figure C | a0c0 | ||

| A3 | Driving-beam test points | a0c0 | ||

| A3 |

|

a0c0 | ||

| A4 |

|

a0c0 | ||

| A4 |

|

a0c0 | ||

| A4 | Tests on complete headlamps | a4c0 | ||

| A4 |

Once the photometric values have been measured according to the prescriptions of this Regulation, in the point for Imax for driving-beam and in

points |

a4c0 | ||

| A4 | The tests shall be carried out: | a0c0 | ||

| A4 1. | Test for stability of photometric performance | a0c0 | ||

| A4 1.1. | Clean headlamp | a0c0 | ||

| A4 |

The headlamp shall be operated for 12 hours as described in paragraph 1.1.1. and checked as prescribed in paragraph 1.1.2. |

a0c0 | ||

| A4 1.1.1. | Test procedure[1] | a0c0 | ||

| A4 | The headlamp shall be operated for a period according to the specified time, so that: | a0c0 | ||

|

A4 |

|

a0c0 | ||

| A4 1.1.1.1. | (a)In the case where only one lighting function (driving or passing-beam or front fog lamp) is to be approved, the corresponding filament and/or LED module(s) is (are) lit for the prescribed time[2]; | a0c0 | ||

| A4 | (b)In the case of a headlamp with a passing-beam and one or more driving-beams or in the case of a headlamp with a passing-beam and a front fog lamp: | a0c0 | ||

| A4 | (i) The headlamp shall be subjected to the following cycle until the time specified is reached: | a0c0 | ||

| A4 |

15 minutes, principal passing-beam filament or principal passing-beam LED module(s) lit; |

a0c0 | ||

| A4 | 5 minutes, all filaments and/or LED module(s) lit. | a0c0 | ||

| A4 |

(ii) If the applicant declares that the headlamp is to be used with only the passing-beam lit or only the driving-beam(s) lit[3] at a time, the test shall be carried out in accordance with this condition, activating[2] successively the passing-beam half of the time and the driving-beam(s) (simultaneously) for half the time specified in paragraph 1.1. above. |

a0c0 | ||

| A4 | (c) In the case of a headlamp with a front fog lamp and one or more driving-beams: | a0c0 | ||

| A4 | (i) The headlamp shall be subjected to the following cycle until the time specified is reached: | a0c0 | ||

| A4 | 15 minutes, front fog lamp lit; | a0c0 | ||

| A4 | 5 minutes, all filaments and/or all LED modules lit. | a0c0 | ||

| A4 |

(ii) If the applicant declares that the headlamp is to be used with only the front fog lamp lit or only the driving-beam(s) lit[3] at a time, the test shall be carried out in accordance with this condition, activating[2] successively the front fog lamp half of the time and the driving-beam(s) (simultaneously) for half the time specified in paragraph 1.1. above. |

a0c0 | ||

| A4 | (d) In the case of a headlamp with a passing-beam, one or more driving-beams and a front fog lamp: | a0c0 | ||

| A4 | (i) The headlamp shall be subjected to the following cycle until the time specified is reached: | a0c0 | ||

| A4 |

15 minutes, principal passing-beam filament or principal passing-beam LED module(s) lit; |

a0c0 | ||

| A4 | 5 minutes, all filaments and/or all LED modules lit. | a0c0 | ||

| A4 |

(ii) If the applicant declares that the headlamp is to be used with only the passing-beam lit or only the driving-beam(s)[3] lit at a time, the test shall be carried out in accordance with this condition, activating[2] successively the principal passing-beam half of the time and the driving-beam(s) for half the time specified in paragraph 1.1. above, while the front fog lamp is subjected to a cycle of 15 minutes off and 5 minutes lit for half of the time and during the operation of the driving-beam; |

a0c0 | ||

| A4 |

(iii) If the applicant declares that the headlamp is to be used with only the passing-beam lit or only the front fog lamp[3] lit at a time, the test shall be carried out in accordance with this condition, activating[2] successively the principal passing-beam half of the time and the front fog lamp for half of the time specified in paragraph 1.1. above, while the driving-beam(s) is(are) subjected to a cycle of 15 minutes off and 5 minutes lit for half of the time and during the operation of the principal passing-beam; |

a0c0 | ||

| A4 |

(iv) If the applicant declares that the headlamp is to be used with only the passing-beam lit or only the driving-beam(s)[3] lit or only the front fog lamp[3] lit at a time, the test shall be carried out in accordance with this condition, activating[2] successively the principal passing-beam one third of the time, the driving-beam(s) one third of the time and the front fog lamp for one third of the time specified in paragraph 1.1. above. |

a0c0 | ||

| A4 |

(e) In the case of a passing-beam designed to provide bend lighting with the addition of a filament light source and/or one or more LED module(s), this light source and/or LED module(s) shall be switched on for one minute, and switched off for nine minutes during the activation of the passing-beam only (see Annex 4 - Appendix 1). |

a0c0 | ||

|

A4 |

|

a0c0 | ||

|

A4 |

|

a0c0 | ||

| A4 1.1.1.2. | Test voltage | a0c0 | ||

| A4 | The voltage shall be applied to the terminals of the test sample as follows: | a0c0 | ||

| A4 | (a) In case of replaceable filament light source(s) operated directly under vehicle voltage system conditions: | a0c0 | ||

| A4 |

The test shall be performed at 6.3 V, 13.2 V or 28.0 V as applicable except if the applicant specifies that the test sample may be used at a different voltage. In this case, the test shall be carried out with the filament light source operated at the highest voltage that can be used. |

a0c0 | ||

| A4 |

(b) In case of replaceable gas discharge light source(s): The test voltage for the electronic light source control-gear is 13.2± 0.1 volts for 12 V vehicle voltage system, or otherwise specified in the application for approval. |

a0c0 | ||

| A4 |

(c) In the case of non-replaceable light source operated directly under vehicle voltage system conditions: All measurements on lighting units equipped with non-replaceable light sources (filament light sources and/ or others) shall be made at 6.3 V, 13.2 V or 28.0 V or at other voltages according to the vehicle voltage system as specified by the applicant respectively. |

a0c0 | ||

| A4 | (d) In the case of light sources, replaceable or non-replaceable, being operated independently from vehicle supply voltage and fully controlled by the system, or, in the case of light sources supplied by a supply and operating device, the test voltages as specified above shall be applied to the input terminals of that device. The test laboratory may require from the manufacturer the supply and operating device or a special power supply needed to supply the light source(s). | a0c0 | ||

| A4 |

(e) LED module(s) shall be measured at 6.75 V, 13.2 V or 28.0 V respectively, if not otherwise specified within this Regulation. LED module(s) operated by an electronic light source control gear, shall be measured as specified by the applicant. |

a0c0 | ||

| A4 |

(f) Where signalling lamps are grouped, combined or reciprocally incorporated into the test sample and operating at voltages other than the nominal rated voltages of 6 V, 12 V or 24 V respectively, the voltage shall be adjusted as declared by the manufacturer for the correct photometric functioning of that lamp. |

a0c0 | ||

| A4 1.1.2. | Test results | a0c0 | ||

| A4 1.1.2.1. | Visual inspection | a0c0 | ||

| A4 | Once the headlamp has been stabilized to the ambient temperature, the headlamp lens and the external lens, if any, shall be cleaned with a clean, damp cotton cloth. It shall then be inspected visually; no distortion, deformation, cracking or change in colour of either the headlamp lens or the external lens, if any, shall be noticeable. | a0c0 | ||

| A4 1.1.2.2. | Photometric test | a1c0 | ||

| A4 | To comply with the requirements of this Regulation, the photometric values shall be verified in the following points: | a1c0 | ||

| A4 | Passing-beam: | a1c0 | ||

| A4 |

50 R - B 50 L - |

a1c0 | ||

| A4 |

50 L - B 50 R - |

a1c0 | ||

| A4 | Driving beam: Point I max | a1c0 | ||

| A4 | Another aiming may be carried out to allow for any deformation of the headlamp base due to heat (the change of the position of the cut-off line is covered in paragraph 2. of this annex). | a1c0 | ||

| A4 |

a 10 per cent discrepancy between the photometric characteristics and the values measured prior to the test is permissible including the tolerances of the photometric procedure. |

a1c0 | ||

| A4 1.2. | Dirty headlamp | a0c0 | ||

| A4 |

After being tested as specified in paragraph 1.1. above, the headlamp shall be operated for one hour as described in paragraph 1.1.1., after being prepared as prescribed in paragraph 1.2.1., and checked as prescribed in paragraph 1.1.2. |

a0c0 | ||

| A4 1.2.1. | Preparations of the headlamp | a0c0 | ||

| A4 1.2.1.1. | Test mixture | a3c0 | ||

| A4 1.2.1.1.1. | For headlamp with the outside lens in glass: | a3c0 | ||

| A4 | The mixture of water and a polluting agent to be applied to the headlamp shall be composed of: | a3c0 | ||

| A4 | 9 parts by weight of silica sand with a particle size of 0-100 μm, | a3c0 | ||

| A4 |

1 part by weight of vegetal carbon dust |

a3c0 | ||

| A4 |

0.2 parts by weight of NaCMC |

a3c0 | ||

| A4 |

|

a3c0 | ||

| A4 |

an appropriate quantity of distilled water, with a conductivity of ≤ 1 |

a3c0 | ||

| A4 | The mixture must not be more than 14 days old. | a3c0 | ||

| A4 1.2.1.1.2. |

For headlamp with |

a4c0 | ||

| A4 | The mixture of water and polluting agent to be applied to the headlamp shall be composed of: | a4c0 | ||

| A4 | (a) 9 parts by weight of silica sand with a particle size of 0-100 μm | a4c0 | ||

| A4 | (b) 1 part by weight of vegetal carbon dust produced from beech wood with a particle size of 0-100 μm, | a4c0 | ||

| A4 |

(c) 0.2 part by weight of NaCMC[3], |

a4c0 | ||

| A4 | (d) 5 parts by weight of sodium chloride (pure at 99 per cent), | a4c0 | ||

| A4 | (e) 13 parts by weight of distilled water with a conductivity of ≤ 1 mS/m, | a4c0 | ||

| A4 |

(f) 2 ± 1 |

a4c0 | ||

| A4 | The mixture shall not be more than 14 days old. | a4c0 | ||

|

A4 |

|

a0c0 | ||

|

A4 |

|

a0c0 | ||

| A4 1.2.1.2. | Application of the test mixture to the headlamp | a0c0 | ||

| A4 | The test mixture shall be uniformly applied to the entire light-emitting surface of the headlamp and then left to dry. This procedure shall be repeated until the illumination value has dropped to 15-20 per cent of the values measured for each following point under the conditions described in this annex: | a0c0 | ||

| A4 | Point of Emax in passing-beam/driving-beam and in driving-beam only, | a0c0 | ||

| A4 | 50 R and 50 V[6] for a headlamp producing only a passing-beam, designed for right-hand traffic, | a0c0 | ||

| A4 | 50 L and 50 V[6] for a headlamp producing only a passing-beam, designed for left-hand traffic. | a0c0 | ||

|

A4 |

|

a0c0 | ||

| A4 2. | Test for change in vertical position of the cut-off line under the influence of heat | a0c0 | ||

| A4 | This test consists of verifying that the vertical drift of the cut-off line under the influence of heat does not exceed a specified value for an operating headlamp producing a passing-beam. | a0c0 | ||

| A4 | The headlamp tested in accordance with paragraph 1., shall be subjected to the test described in paragraph 2.1., without being removed from or readjusted in relation to its test fixture. | a0c0 | ||

| A4 2.1. | Test | a0c0 | ||

| A4 |

The test shall be carried out in a dry and still atmosphere at an ambient temperature of 23 °C ± 5 °C. |

a0c0 | ||

| A4 | Using a mass production filament lamp or the LED module(s) as submitted with the headlamp, which has (have) been aged for at least one hour, the headlamp shall be operated on the principal passing-beam without being dismounted from or readjusted in relation to its test fixture. (For the purpose of this test, the voltage shall be adjusted as specified in paragraph 1.1.1.2.). The position of the cut-off line in its horizontal part (between vv and the vertical line passing through point B 50 L for right-hand traffic or B 50 R for left-hand traffic) shall be verified 3 minutes (r3) and 60 minutes (r60) respectively after operation. | a0c0 | ||

| A4 | The measurement of the variation in the cut-off line position as described above shall be carried out by any method giving acceptable accuracy and reproducible results. | a0c0 | ||

| A4 2.2. | Test results | a0c0 | ||

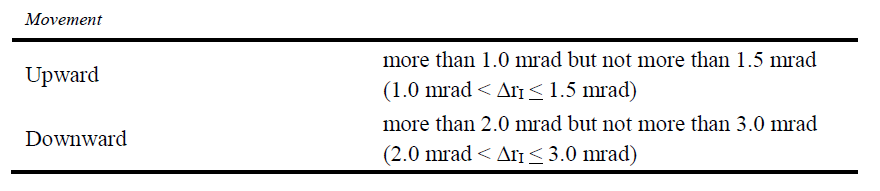

| A4 2.2.1. |

The result expressed in milliradians (mrad) shall be considered as acceptable for a passing beam headlamp when the absolute value Δ r1 = | r3 - r60 | recorded on the headlamp is not more than 1.0 mrad (Δ r1 ≤ 1.0 mrad) upward and not more than 2.0 mrad (Δ r1 ≤ 2.0 mrad) downwards. |

a4c0 | ||

| A4 2.2.2. | However, if this value is: | a4c0 | ||

| A4 |

|

a4c0 | ||

| A4 |

a further sample of a headlamp |

a4c0 | ||

| A4 |

(a) Operation of the passing beam for one hour (the voltage shall be adjusted as specified in paragraph 1.1.1.2.); |

a4c0 | ||

| A4 |

After |

a4c0 | ||

| A4 |

|

a0c0 | ||

| A4 |

|

a0c0 | ||

| A4 |

|

a0c0 | ||

| A4 |

|

a0c0 | ||

| A5 |

|

a0c0 | ||

| A5 |

|

a0c0 | ||

| A5 1. | General | a0c0 | ||

| A5 1.1. | The conformity requirements shall be considered satisfied from a mechanical and a geometrical standpoint, if the differences do not exceed inevitable manufacturing deviations within the requirements of this Regulation. This condition also applies to colour. | a0c0 | ||

| A5 1.2. |

With respect to photometric performances, the conformity of mass-produced headlamps shall not be contested if, when testing photometric performances of any headlamp chosen at random and equipped with a standard (étalon) filament lamp and/or LED module(s), as present in the lamp: |

a0c0 | ||

| A5 1.2.1. | No measured value deviates unfavourably by more than 20 per cent from the value prescribed in this Regulation. For values B 50 L (or R)[1] and zone III, the maximum unfavourable deviation may be respectively: | a0c0 | ||

|

A5 |

|

a0c0 | ||

| A5 | B 50 L (or R): | a0c0 | ||

| A5 | 170 cd equivalent 20 per cent | a0c0 | ||

| A5 | 255 cd equivalent 30 per cent | a0c0 | ||

| A5 | Zone III | a0c0 | ||

| A5 | 255 cd equivalent 20 per cent | a0c0 | ||

| A5 | 380 cd equivalent 30 per cent | a0c0 | ||

| A5 1.2.2. | Or if | a0c0 | ||

| A5 1.2.2.1. |

For the passing-beam, the values prescribed in this Regulation are met at |

a4c0 | ||

| A5 1.2.2.2. |

And if, for the driving-beam, HV being situated within the isolux 0.75 Imax a tolerance of +20 per cent for maximum values and -20 per cent for minimum values is observed for the photometric values at any measuring point specified in paragraph 6.3.2. of this Regulation. |

a0c0 | ||

| A5 1.2.3. |

If the results of the test described above do not meet the requirements, the alignment of the headlamp may be changed, provided that the axis of the beam is not displaced laterally by more than 1° to the right or left. |

a0c0 | ||

| A5 1.2.4. |

If in the case of a lamp equipped with a replaceable filament light source the results of the tests described above do not meet the requirements, tests shall be repeated using another standard (étalon) filament lamp. |

a0c0 | ||

| A5 1.3. | With respect to the verification of the change in vertical position of the cut-off line under the influence of heat, the following procedure shall be applied: | a0c0 | ||

| A5 | One of the sampled headlamps shall be tested according to the procedure described in paragraph 2.1. of Annex 4 after being subjected three consecutive times to the cycle described in paragraph 2.2.2. of Annex 4. | a0c0 | ||

| A5 |

The headlamp shall be considered as acceptable if Δr does not exceed 1.5 mrad. |

a0c0 | ||

| A5 | If this value exceeds 1.5 mrad but is not more than 2.0 mrad, a second sample shall be subjected to the test after which the mean of the absolute values recorded on both samples shall not exceed 1.5 mrad. | a0c0 | ||

| A5 1.4. | If, however, vertical adjustment cannot be performed repeatedly to the required position within the tolerances described in paragraph 6.2.2.3. of this Regulation, one sample shall be tested according to the procedure described in paragraphs 2. and 3. of Annex 9. | a0c0 | ||

| A5 2. | Minimum requirements for verification of conformity by the manufacturer | a0c0 | ||

| A5 | For each type of headlamp the holder of the approval mark shall carry out at least the following tests, at appropriate intervals. The tests shall be carried out in accordance with the provision of this Regulation. | a0c0 | ||

| A5 | If any sampling shows non-conformity with regard to the type of test concerned, further samples shall be taken and tested. The manufacturer shall take steps to ensure the conformity of the production concerned. | a0c0 | ||

| A5 2.1. | Nature of tests | a0c0 | ||

| A5 | Tests of conformity in this Regulation shall cover the photometric characteristics and the verification of the change in vertical position of the cut-off line under the influence of heat. | a0c0 | ||

| A5 2.2. | Methods used in tests | a0c0 | ||

| A5 2.2.1. | Tests shall generally be carried out in accordance with the methods set out in this Regulation. | a0c0 | ||

| A5 2.2.2. | In any test of conformity carried out by the manufacturer, equivalent methods may be used with the consent of the competent Authority responsible for approval tests. The manufacturer is responsible for proving that the applied methods are equivalent to those laid down in this Regulation. | a0c0 | ||

| A5 2.2.3. | The application of paragraphs 2.2.1. and 2.2.2. requires regular calibration of test apparatus and its correlation with measurement made by a competent Authority. | a0c0 | ||

| A5 2.2.4. | In all cases the reference methods shall be those of this Regulation, particular for the purpose of administrative verification and sampling. | a0c0 | ||

| A5 2.3. | Nature of sampling | a0c0 | ||

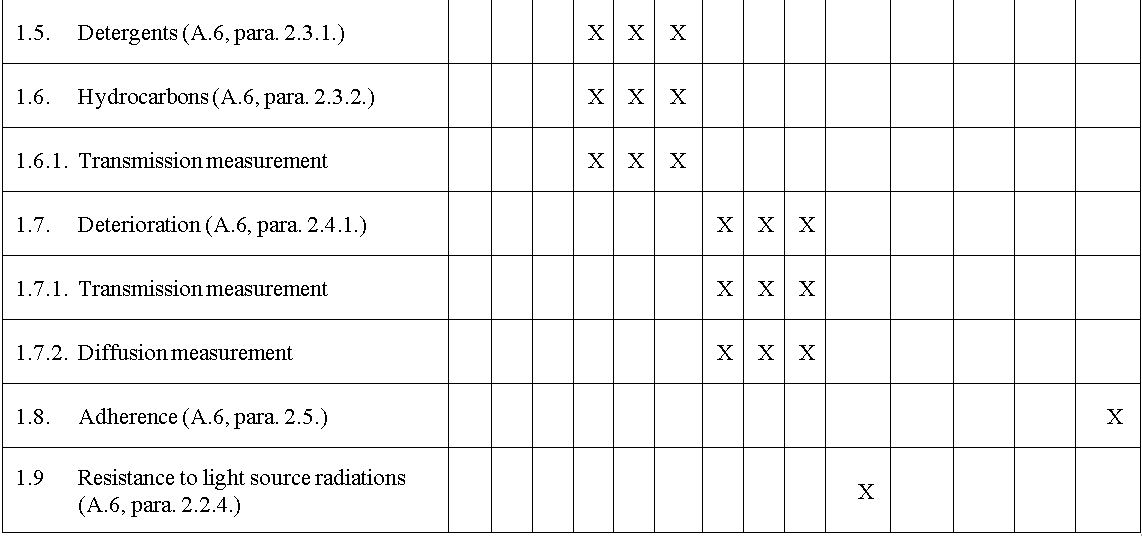

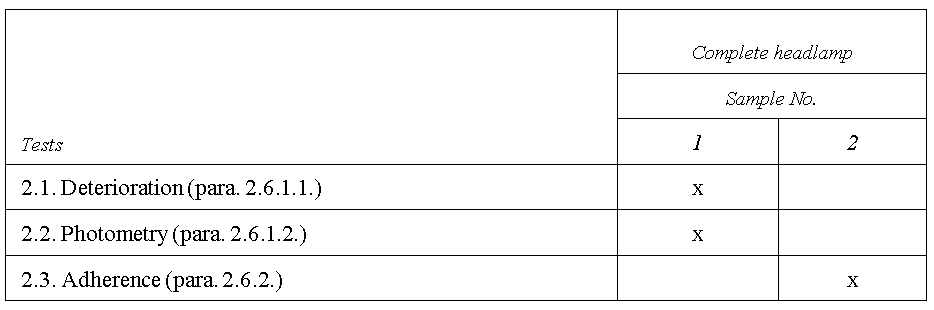

| A5 | Samples of headlamps shall be selected at random from the production of a uniform batch. A uniform batch means a set of headlamps of the same type, defined according to the production methods of the manufacturer. | a0c0 | ||