|

|

|

a4c0 |

| ... |

Regulation |

a0c0 |

| ... | 1. Scope | a0c0 |

| ... | 2. Definitions | a0c0 |

| ... | 3. Application for approval | a0c0 |

| ... | 4. Markings | a0c0 |

| ... | 5. Approval | a0c0 |

| ... | 6. General specifications | a0c0 |

| ... | 7. Special specifications (tests) | a0c0 |

| ... | 8. Conformity of production | a0c0 |

| ... | 9. Penalties for non-conformity of production | a0c0 |

| ... | 10. Production definitively discontinued | a0c0 |

| ... | 11. Names and addresses of Technical Services responsible for conducting approval tests, and of Type Approval Authorities | a0c0 |

| ... | 12. Transitional provisions | a0c0 |

| ... | Annexes | a0c0 |

| ... | 1 Retro-reflecting devices | a0c0 |

| ... | 2 Communication | a0c0 |

| ... | 3 Examples of approval marks | a0c0 |

| ... | 4 Test procedure - Class IA and Class IIIA | a0c0 |

| ... | 5 Specifications of shape and dimensions | a0c0 |

| ... | Appendix - Retro-reflectors for trailers - Classes IIIA and IIIB | a0c0 |

| ... | 6 Colorimetric specifications | a0c0 |

| ... | 7 Photometric specifications | a0c0 |

| ... | 8 Resistance to external agents | a0c0 |

| ... | 9 Stability in time of the optical properties of retro-reflecting devices | a0c0 |

| ... | 10 Resistance to heat | a0c0 |

| ... | 11 Colour-fastness | a0c0 |

| ... | 12 Chronological order of tests | a0c0 |

| ... | 13 Resistance to impact - Class IVA | a0c0 |

| ... | 14 Test procedure - Class IVA | a0c0 |

| ... | 15 Chronological order of tests for Class IVA | a0c0 |

| ... | 16 Test procedure for Classes IB and IIIB devices | a0c0 |

| ... | 17 Minimum requirements for conformity of production control procedures | a0c0 |

| ... | 18 Minimum requirements for sampling by an inspector | a0c0 |

| 1. |

|

a0c0 |

| ... | This Regulation applies to retro-reflecting devices[1] for vehicles of categories L, M, N, O, and T[2]. | a0c0 |

|

|

|

a0c0 |

|

|

|

a0c0 |

| 2. |

|

a0c0 |

|

|

|

a0c0 |

| ... | For the purpose of this Regulation, | a0c0 |

| 2.1. | The definitions given in Regulation No. 48 and its series of amendments in force at the time of application for type approval shall apply to this Regulation. | a0c0 |

| 2.2. | "Retro-reflection " means the reflection in which light is reflected in directions close to the direction from which it came. This property is maintained over wide variations of the illumination angle. | a0c0 |

| 2.3. | "Retro-reflecting optical unit" means a combination of optical components producing retro-reflection. | a0c0 |

| 2.4. | "Retro-reflecting device"[1] means an assembly ready for use and comprising one or more retro-reflecting optical units. | a0c0 |

| 2.5. | "Angle of divergence" means the angle between the straight lines connecting the centre of reference to the centre of the receiver and to the centre of the source of illumination. | a0c0 |

| 2.6. | "Illumination angle" means the angle between the axis of reference and the straight line connecting the centre of reference to the centre of the source of illumination. | a0c0 |

| 2.7. | "Angle of rotation" means the angle through which the retro-reflecting device is rotated about its axis of reference starting from one given position. | a0c0 |

| 2.8. | "Angular diameter of the retro-reflecting device" means the angle subtended by the greatest dimension of the visible area of the illuminating surface, either at the centre of the source of illumination or at the centre of the receiver. | a0c0 |

| 2.9. | "Illumination of the retro-reflecting device" is the abbreviated expression used conventionally to designate the illumination measured in a plane perpendicular to the incident rays and passing through the centre of reference. | a0c0 |

| 2.10. | "Coefficient of luminous intensity (CIL)" means the quotient of the luminous intensity reflected in the direction considered, divided by the illumination of the retro-reflecting device for given angles of illumination, divergence and rotation. | a0c0 |

| 2.11. | The symbols and units used in this Regulation are given in Annex 1 to this Regulation. | a0c0 |

| 2.12. | A type of "retro-reflecting device" is defined by the models and descriptive literature submitted with the application for approval. Retro-reflecting devices can be considered as belonging to the same type if they have one or more "retro-reflecting optical units" which are identical with those of the standard model, or if not identical are symmetrical and suitable for mounting one on the left and one on the right side of the vehicle, and if their other parts differ from those of the standard model only in ways not affecting the properties to which this Regulation applies. | a0c0 |

| 2.13. |

Retro-reflecting devices are divided into three classes according to their photometric characteristics: Class IA or IB, Class IIIA or IIIB and Class IVA. |

a0c0 |

| 2.14. |

Retro-reflecting devices of Classes IB and IIIB are devices combined with other signal lamps which are not watertight according to Annex 8, paragraph 1.1., and which are integrated into the body of a vehicle. |

a0c0 |

| 2.15. |

"Colour of the reflected light of the device" - The definitions of the colour of the reflected light are given in paragraph 2.30. of Regulation No. 48. |

a0c0 |

| 3. |

|

a0c0 |

| 3.1. | The application for approval shall be submitted by the holder of the trade name or mark, or if necessary by his duly accredited representative. | a0c0 |

| ... | At the choice of the applicant, it will specify that the device may be installed on a vehicle with different inclinations of the reference axis in respect to the vehicle reference planes and to the ground or, in the case of Classes IA, IB and IVA retro-reflectors, rotate around its reference axis; these different conditions of installation shall be indicated in the communication form. It shall be accompanied by: | a0c0 |

| 3.1.1. | Drawings, in triplicate, in sufficient detail to permit identification of the type, showing geometrically the position(s) in which the retro-reflecting device may be fitted to the vehicle, and in case of class IB or IIIB-retro-reflectors details of installation. The drawings must show the position intended for the approval number and class indicator in relation to the circle of the approval mark; | a0c0 |

| 3.1.2. | A brief description giving the technical specifications of the materials of which the retro-reflecting optical unit is made; | a0c0 |

| 3.1.3. | Samples of the retro-reflecting device of a colour specified by the manufacturer and, if necessary, the means of fixation; the number of samples to be submitted is specified in Annex 4 to this Regulation; | a0c0 |

| 3.1.4. | If necessary, two samples in other colour(s) for simultaneous or subsequent extension of the approval to devices in other colour(s); | a0c0 |

| 3.1.5. | In the case of devices of Class IVA: samples of the retro-reflecting device and, if necessary, the means of fixation; the number of samples to be submitted is specified in Annex 14 to this Regulation. | a0c0 |

| 4. |

|

a0c0 |

| 4.1. | Every retro-reflecting device submitted for approval must bear: | a0c0 |

| 4.1.1. | The trade name or mark of the applicant; | a0c0 |

| 4.1.2. | The word "TOP" inscribed horizontally on the highest part of the illuminating surface, if such an indication is necessary to determine without ambiguity the angle or angles of rotation prescribed by the manufacturer. | a0c0 |

|

|

|

a2c0 |

| 4.2. | A space of sufficient size to accommodate the approval mark shall be provided on every device. This space shall be shown on the drawings referred to in paragraph 3.1.1. above. | a0c0 |

| 4.3. | The markings must be visible from the outside when the retro-reflecting device is fitted on the vehicle. | a0c0 |

| 4.4. | The markings must be clearly legible and be indelible. | a0c0 |

| 5. |

|

a0c0 |

| 5.1. | If all the samples submitted meet the requirements of this Regulation, approval shall be granted. | a0c0 |

| 5.2. |

If the approval granted in respect of a retro-reflecting device is extended to other such devices differing only in colour, the two samples in any other colour submitted in conformity with paragraph 3.1.4. of this Regulation shall be required to meet only the colorimetric |

a2c0 |

| 5.3. | An approval number shall be assigned to each type approved. Its first two digits (at present 02, corresponding to the 02 series of amendments which entered into force on 1 July 1985) shall indicate the series of amendments incorporating the most recent major technical amendments made to the Regulation at the time of issue of the approval. A Contracting Party shall not assign the same number to another type of retro-reflecting device covered by this Regulation except in the case of an extension of the approval to a device differing only in colour. | a0c0 |

| 5.4. | Notice of approval or of extension or refusal of approval of a type of retro-reflecting device pursuant to this Regulation shall be communicated to the Parties to the Agreement which apply this Regulation, by means of a form conforming to the model in Annex 2 to this Regulation. | a0c0 |

| 5.5. | There shall be affixed to every retro-reflecting device conforming to a type approved under this Regulation, in the space referred to in paragraph 4.2. above and in addition to the markings prescribed in paragraph 4.1. above. | a0c0 |

| 5.5.1. | An international approval mark consisting of: | a0c0 |

| 5.5.1.1. | A circle surrounding the letter "E" followed by the distinguishing number of the country which has granted approval;[4] | a0c0 |

|

|

|

a0c0 |

| 5.5.1.2. | An approval number; | a0c0 |

| 5.5.1.3. | A group of symbols IA, IB, IIIA, IIIB or IVA showing the class of the approved retro-reflecting device. | a0c0 |

| 5.6. | When two or more lamps are part of the same unit of grouped, combined or reciprocally incorporated lamps (including a retro-reflector), approval is granted only if each of these lamps satisfies the requirements of this Regulation or of another Regulation. Lamps not satisfying any one of those Regulations shall not be part of such a unit of grouped, combined or reciprocally incorporated lamps. | a0c0 |

| 5.6.1. | Where grouped, combined or reciprocally incorporated lamps comply with the requirements of several Regulations, a single international approval mark may be applied, consisting of a circle surrounding the letter "E" followed by the distinguishing number of the country which has granted the approval, an approval number and, if necessary, the required arrow. This approval mark may be placed anywhere on the grouped, combined or reciprocally incorporated lamps provided that: | a0c0 |

| 5.6.1.1. | It is visible after their installation; | a0c0 |

| 5.6.1.2. | No part of the grouped, combined or reciprocally incorporated lamps that transmits light can be removed without at the same time removing the approval mark. | a0c0 |

| 5.6.2. | The identification symbol for each lamp appropriate to each Regulation, under which approval has been granted, together with the corresponding series of amendments incorporating the most recent major technical amendments to the Regulation at the time of issue of the approval, shall be marked: | a0c0 |

| 5.6.2.1. | Either on the appropriate light-emitting surface, | a0c0 |

| 5.6.2.2. | Or in a group, in such a way that each lamp of the grouped, combined or reciprocally incorporated lamps may be clearly identified (see the possible examples shown in Annex 3). | a0c0 |

| 5.6.3. | The size of the components of a single approval mark shall not be less than the minimum size required for the smallest of the individual marks by a Regulation under which approval has been granted. | a0c0 |

| 5.6.4. | An approval number shall be assigned to each type approved. The same Contracting Party may not assign the same number to another type of grouped, combined or reciprocally incorporated lamps covered by this Regulation. | a0c0 |

| 5.7. | The approval mark must be clearly legible and indelible. | a0c0 |

| 5.8. | Annex 3 to this Regulation gives examples of arrangements of approval marks for a single lamp (Figure 1) and for grouped, combined or reciprocally incorporated lamps (Figure 2) with all the additional symbols referred to above. | a0c0 |

| 6. |

|

a0c0 |

| ... |

|

a3c0 |

| ... |

|

a3c0 |

| 6.1. | Retro-reflecting devices must be so constructed that they function satisfactorily and will continue to do so in normal use. In addition, they must not have any defect in design or manufacture that is detrimental to their efficient operation or to their maintenance in good condition. | a0c0 |

| 6.2. | The components of retro-reflecting devices must not be capable of being easily dismantled. | a0c0 |

| 6.3. | Retro-reflecting optical units may not be replaceable. | a0c0 |

| 6.4. | The outer surface of retro-reflecting devices must be easy to clean. Hence it must not be a rough surface; any protuberances it may exhibit must not prevent easy cleaning. | a0c0 |

| 6.5. | For devices of Class IVA their means of fixation shall be such that they allow a stable and durable connection between the device and the vehicle. | a0c0 |

| 6.6. | There shall be no access to the inner surface of the retro-reflectors when in normal use. | a0c0 |

| 7. |

|

a0c0 |

| 7.1. |

Retro-reflecting devices must also satisfy the conditions as to dimensions and shape, and the colorimetric, photometric, physical and mechanical requirements set forth in Annexes 5 to 11 and 13 to this Regulation. The test procedures are described in Annex 4 (Classes IA, IIIA), Annex 14 (Class IVA) and Annex 16 (Classes IB, IIIB). |

a0c0 |

| 7.2. | Depending on the nature of the materials of which the retro-reflecting devices and, in particular, their optical units, are made, the competent authorities may authorize laboratories to omit certain unnecessary tests, subject to the express reservation that such omission must be mentioned under "Remarks" on the form notifying approval. | a0c0 |

| 8. |

|

a0c0 |

| ... | The conformity of production procedures shall comply with those set out in the Agreement, Appendix 2 (E/ECE/324-E/ECE/TRANS/505/Rev.2), with the following requirements: | a0c0 |

| 8.1 |

The compliance with the requirements set forth in paragraphs 6. and 7. above shall be verified as follows: |

a3c0 |

|

|

The minimum requirements for conformity of production control procedures set forth in Annex 17 to this Regulation shall be complied with. | a3c0 |

|

|

The minimum requirements for sampling by an inspector set forth in Annex 18 to this Regulation shall be complied with. |

a3c0 |

|

|

The Type Approval Authority which has granted type approval may at any time verify the conformity control methods applied in each production facility. The normal frequency of these verifications shall be once every two years. | a3c0 |

| 9. |

|

a0c0 |

| 9.1. | The approval granted for a type of retro-reflecting device may be withdrawn if the requirements are not complied with or if a retro-reflecting device bearing the approval mark does not conform to the type approved. | a0c0 |

| 9.2. | If a Contracting Party to the Agreement applying this Regulation withdraws an approval it has previously granted, it shall forthwith so notify the other Contracting Parties applying this Regulation by means of a communication form conforming to the model in Annex 2 to this Regulation. | a0c0 |

| 10. |

|

a0c0 |

| ... | If the holder of the approval completely ceases to manufacture a type of retro-reflecting device approved in accordance with this Regulation, he shall so inform the Type Approval Authority which granted the approval. Upon receiving the relevant communication, that Authority shall inform thereof the other Parties to the 1958 Agreement applying this Regulation by means of a communication form conforming to the model in Annex 2 to this Regulation. | a0c0 |

| 11. |

|

a0c0 |

| ... | The Contracting Parties to the Agreement applying this Regulation shall communicate to the United Nations secretariat the names and addresses of the Technical Services responsible for conducting approval tests and of the Type Approval Authorities which grant approval and to which forms certifying approval or extension or refusal or withdrawal of approval, issued in other countries, are to be sent. | a0c0 |

| 12. |

|

a0c0 |

| ... |

|

a4c0 |

| 12.1. |

|

a4c0 |

| 12.2. |

|

a4c0 |

| 12.3. |

|

a4c0 |

| 12.3.1. |

|

a4c0 |

| 12.3.2. |

|

a4c0 |

|

|

|

a4c0 |

|

|

|

a4c0 |

|

|

|

a4c0 |

|

|

|

a4c0 |

|

|

|

a4c0 |

| A1 |

|

a0c0 |

| A1 |

|

a0c0 |

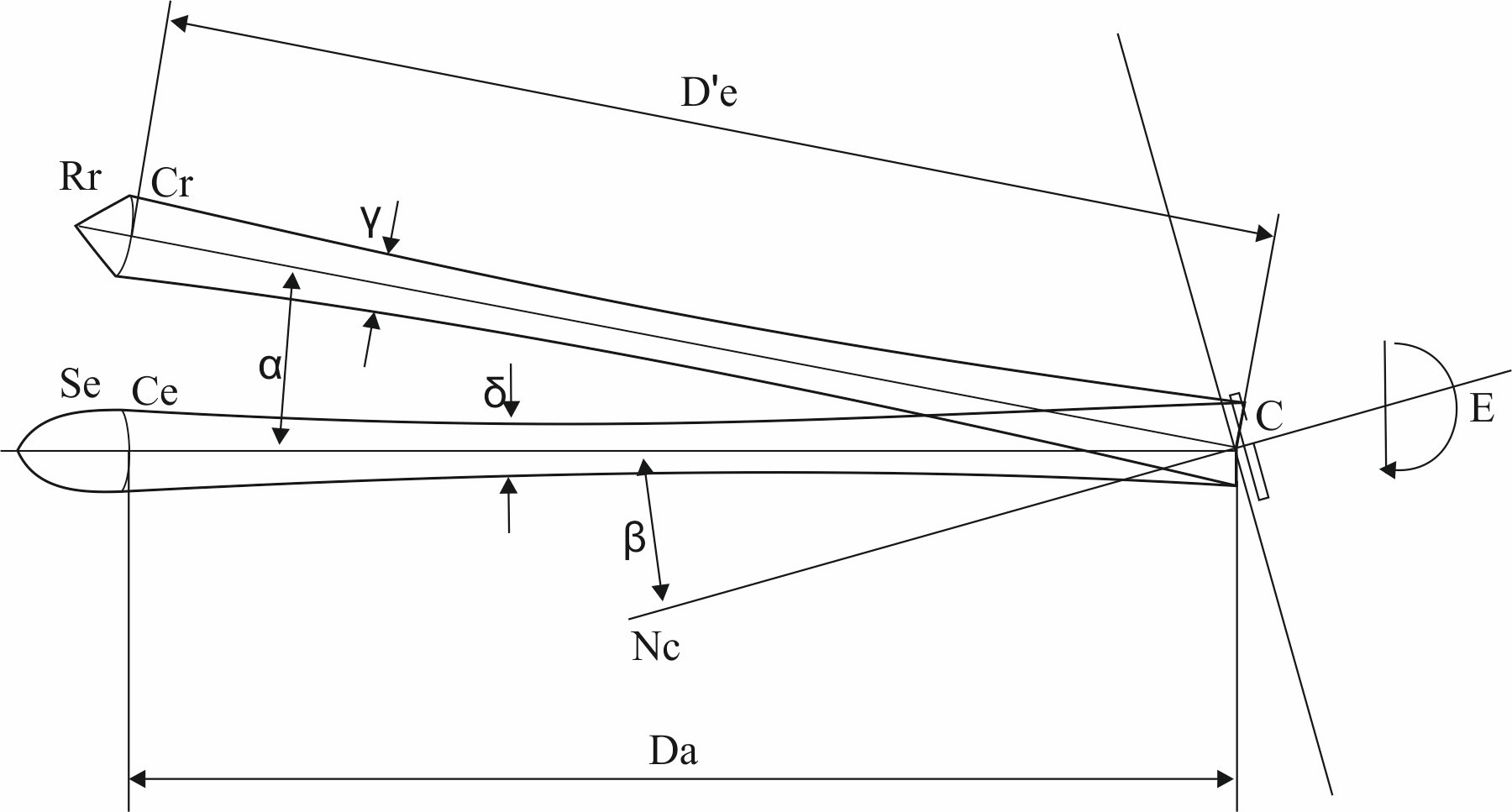

| A1 | Symbols and units | a0c0 |

| A1 | A = Area of the illuminating surface of the retro-reflecting device (cm2) | a0c0 |

| A1 | C = Centre of reference | a0c0 |

| A1 | NC = Axis of reference | a0c0 |

| A1 | Rr = Receiver, observer or measuring device | a0c0 |

| A1 | Cr = Centre of receiver | a0c0 |

| A1 | Ør = Diameter of receiver Rr if circular (cm) | a0c0 |

| A1 | Se = Source of illumination | a0c0 |

| A1 | Cs = Centre of source of illumination | a0c0 |

| A1 | Øs = Diameter of source of illumination (cm) | a0c0 |

| A1 | De = Distance from centre Cs to centre C (m) | a0c0 |

| A1 | D'e = Distance from centre Cr to centre C (m) | a0c0 |

| A1 | Note: In general, De and D'e are very nearly the same and under normal conditions of observation it may be assumed that De = D'e. | a0c0 |

| A1 | D = Observation distance from and from beyond which the illuminating surface appears to be continuous | a0c0 |

| A1 | α = Angle of divergence | a0c0 |

| A1 | β = Illumination angle. With respect to the line CsC which is always considered to be horizontal, this angle is prefixed by the signs - (left), + (right), + (up) or - (down), according to the position of the source Se in relation to the axis NC, as seen when looking towards the retro-reflecting device. For any direction defined by two angles, vertical and horizontal, the vertical angle is always given first. | a0c0 |

| A1 | γ = Angular diameter of the measuring device Rr as seen from point C | a0c0 |

| A1 | δ = Angular diameter of the source Se as seen from point C | a0c0 |

| A1 | ε = Angle of rotation. This angle is positive when the rotation is clockwise as seen when looking towards the illuminating surface. If the retro-reflecting device is marked "TOP", the position thus indicated is taken as the origin. | a0c0 |

| A1 | E = Illumination of the retro-reflecting device (lux) | a0c0 |

| A1 | CIL = Coefficient of luminous intensity (millicandelas/lux) | a0c0 |

| A1 | Angles are expressed in degrees and minutes. | a0c0 |

| A1 |

|

a0c0 |

| A1 | Symbols | a0c0 |

| A1 |

|

a0c0 |

| A1 | Elevation | a0c0 |

| A2 |

|

a0c0 |

| A2 |

|

a0c0 |

| A2 | (Maximum format: A4 (210 x 297 mm)) | a0c0 |

| A2 |

|

a0c0 |

| A2 | of a type of retro-reflecting device pursuant to Regulation No. 3. | a0c0 |

| A2 | Approval No.:....................Extension No.:.................... | a0c0 |

| A2 1. | Trade name or mark of the device: | a0c0 |

| A2 2. | Manufacturer's name for the type of device: | a0c0 |

| A2 3. | Manufacturer's name and address: | a0c0 |

| A2 4. | If applicable, name and address of the manufacturer's representative: | a0c0 |

| A2 5. | Submitted for approval on: | a0c0 |

| A2 6. | Technical Service responsible for conducting approval tests: | a0c0 |

| A2 7. | Date of test report: | a0c0 |

| A2 8. | Number of test report: | a0c0 |

| A2 9. | Concise description: | a2c0 |

| A2 | In isolation/part of an assembly of devices:[2] | a2c0 |

| A2 | Colour of light emitted: white/red/amber[2] | a2c0 |

| A2 | Installation as an integral part of a lamp which is integrated into the body of a vehicle: yes/no[2] | a2c0 |

| A2 | Geometric conditions of installation and relating variations, if any: | a2c0 |

| A2 |

|

a2c0 |

| A2 10. | Position of the approval mark: | a0c0 |

| A2 11. | Reason(s) for extension (if applicable): | a0c0 |

| A2 12. | Approval granted/refused/extended/withdrawn:[2] | a0c0 |

| A2 13. | Place: | a0c0 |

| A2 14. | Date: | a0c0 |

| A2 15. | Signature: | a0c0 |

| A2 16. | The following documents, bearing the approval number shown above, are available on request: | a0c0 |

|

A2 |

|

a0c0 |

|

A2 |

|

a0c0 |

| A3 |

|

a0c0 |

| A3 |

|

a0c0 |

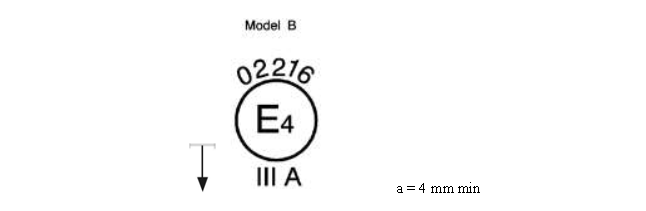

| A3 | Figure 1 | a2c0 |

| A3 | Marking for single lamps | a2c0 |

| A3 |

|

a2c0 |

| A3 |

|

a2c0 |

| A3 |

|

a2c0 |

| A3 |

Note: The above approval number must be placed close to, but in any position in relation to, the circle surrounding the letter "E". The digits constituting the approval number must face the same way as the "E". The group of symbols indicating the class must be diametrically opposite the approval number.

|

a2c0 |

| A3 | These sketches show various possible arrangements and are given as examples only. | a0c0 |

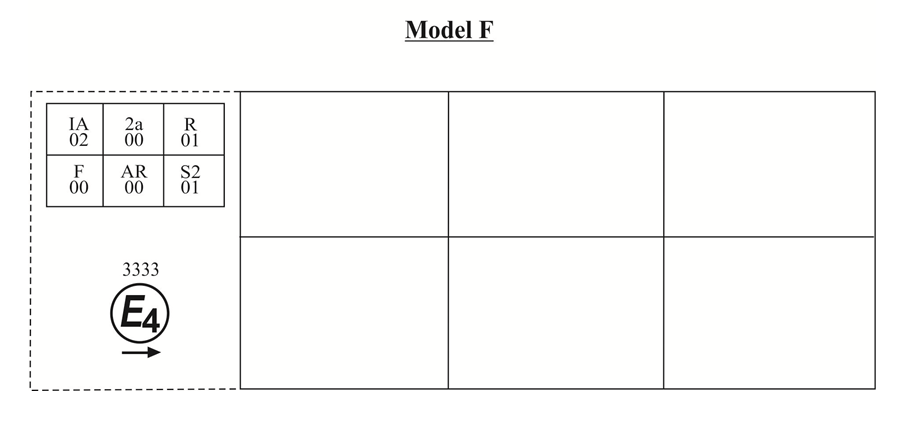

| A3 | The above approval mark affixed to a retro-reflecting device shows that the type of device concerned has been approved in the Netherlands (E 4) under approval number 02216. The approval number shows that approval was granted in accordance with the requirements of the Regulation as modified by the 02 series of amendments. | a0c0 |

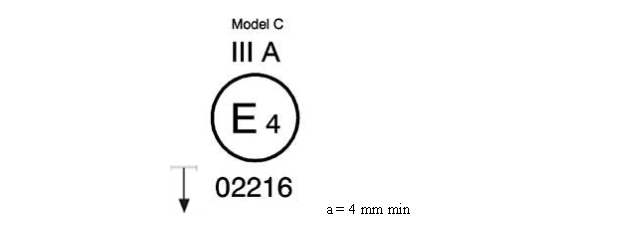

| A3 | Figure 2 | a0c0 |

| A3 | Simplified marking for grouped, combined or reciprocally incorporated lamps | a0c0 |

| A3 |

|

a0c0 |

| A3 |

|

a0c0 |

| A3 |

|

a0c0 |

| A3 | Note: The three examples of approval marks, models D, E and F, represent three possible variants of the marking of a lighting device when two or more lamps are part of the same unit of grouped, combined or reciprocally incorporated lamps. This approval mark shows that the device was approved in the Netherlands (E 4) under approval number 3333 and comprising: | a0c0 |

| A3 | A retro-reflector of Class IA approved in accordance with the 02 series of amendments to Regulation No. 3; | a0c0 |

| A3 | A rear direction indicator of category 2a approved in accordance with Regulation No. 6 in its original form; | a0c0 |

| A3 | A red rear position lamp (R) approved in accordance with the 01 series of amendments to Regulation No. 7; | a0c0 |

| A3 | A rear fog lamp (F) approved in accordance with Regulation No. 38 in its original form; | a0c0 |

| A3 | A reversing lamp (AR) approved in accordance with Regulation No. 23 in its original form; | a0c0 |

| A3 | A stop lamp with two levels of illumination (S2) approved in accordance with the 01 series of amendments to Regulation No. 7. | a0c0 |

| A4 |

|

a0c0 |

| A4 |

|

a0c0 |

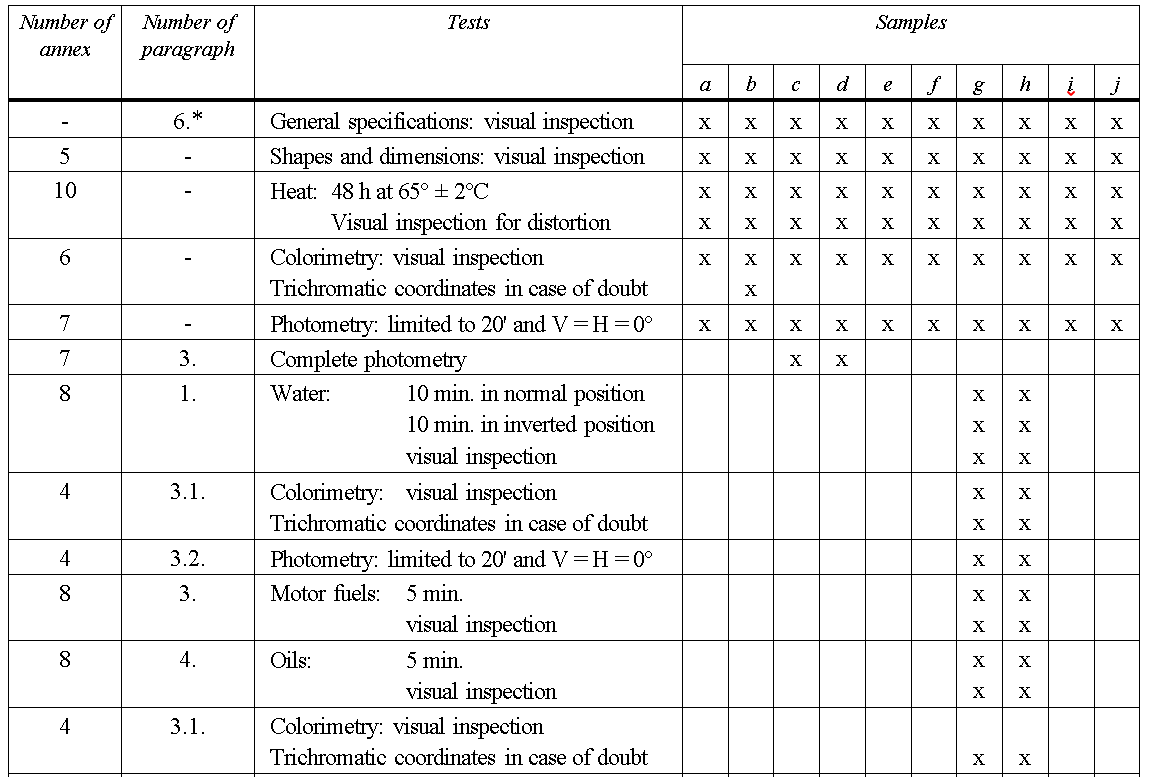

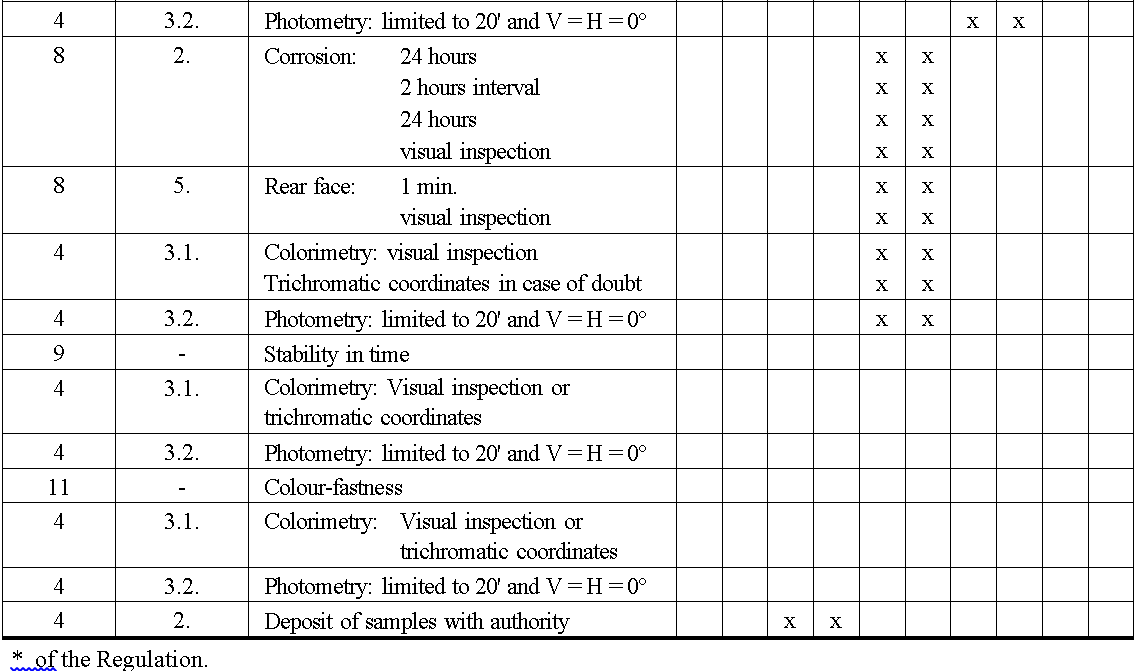

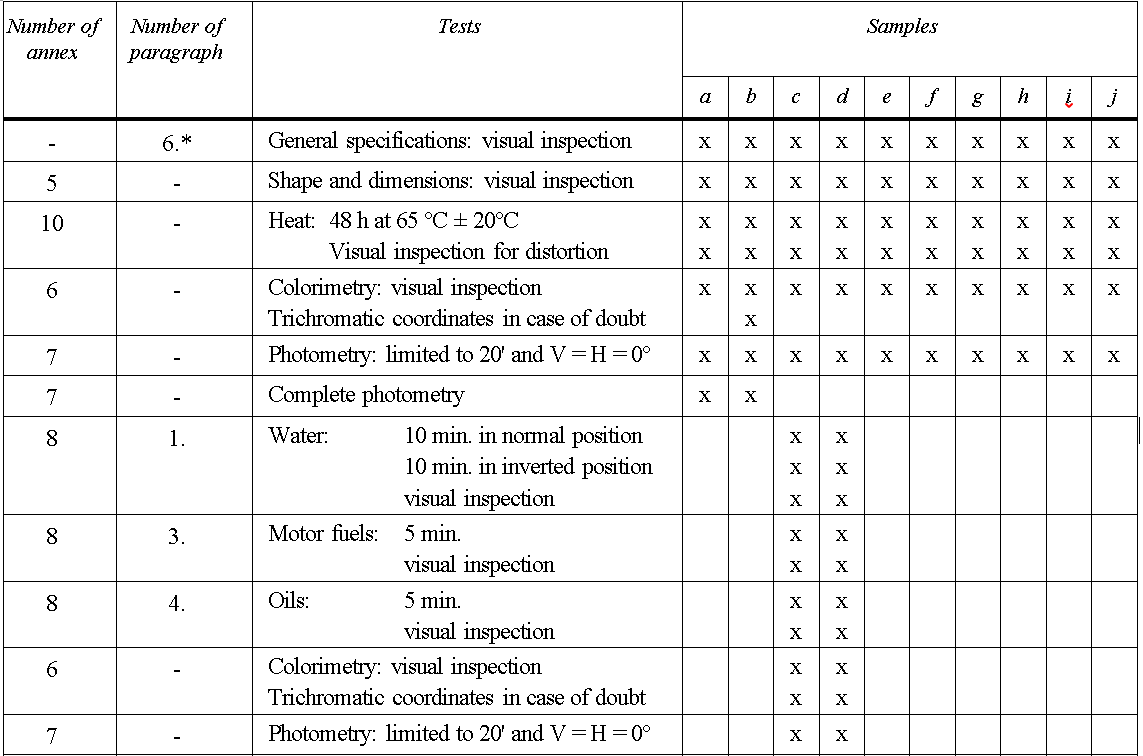

| A4 1. | The applicant shall submit for approval ten samples which shall be tested in the chronological order indicated in Annex 12. | a0c0 |

| A4 2. |

After verification of the general specifications (paragraph 6. of the Regulation) and the specifications of shape and dimensions (Annex 5), the ten samples shall be subjected to the heat resistance test described in Annex 10 and at least one hour after this test examined as to their colorimetric characteristics and CIL (Annex 7) for an angle of divergence of 20' and an illumination angle V = H = 0° or if necessary, in the position defined in Annex 7, paragraphs 4. and 4.1. The two retro-reflecting devices giving the minimum and maximum values shall then be fully tested as shown in Annex 7. These two samples shall be kept by the laboratories for any further checks which may be found necessary. The other eight samples shall be divided into four groups of two: |

a0c0 |

| A4 | First group: | a0c0 |

| A4 | The two samples shall be subjected successively to the water penetration test (Annex 8, paragraph 1.1.) and then, if this test is satisfactory, to the tests for resistance to fuels and lubricants (Annex 8, paragraphs 3. and 4.). | a0c0 |

| A4 | Second group: | a0c0 |

| A4 | The two samples shall, if necessary, be subjected to the corrosion test (Annex 8, paragraph 2.), and then to the abrasive-strength test of the rear face of the retro-reflecting device (Annex 8, paragraph 5.). | a0c0 |

| A4 | Third group: | a0c0 |

| A4 | The two samples shall be subjected to the test for stability in time of the optical properties of retro-reflecting device (Annex 9). | a0c0 |

| A4 | Fourth group: | a0c0 |

| A4 | The two samples shall be subjected to the colour-fastness test (Annex 11). | a0c0 |

| A4 3. | After undergoing the tests referred to in the above paragraph, the retro-reflecting devices in each group must have: | a0c0 |

| A4 3.1. | A colour which satisfies the conditions laid down in Annex 6. This shall be verified by a qualitative method and, in case of doubt, confirmed by a quantitative method. | a0c0 |

| A4 3.2. |

A CIL which satisfies the conditions laid down in Annex 7. The verification shall be performed only for an angle of divergence of 20' and an illumination angle of V = H = 0° or, if necessary, in the position specified in Annex 7, paragraphs 4. and 4.1. |

a0c0 |

| A5 |

|

a0c0 |

| A5 |

|

a0c0 |

| A5 1. | Shape and dimensions of retro-reflecting devices in Class IA or IB | a1c0 |

| A5 1.1. |

The shape of the illuminating surfaces |

a1c0 |

| A5 1.2. |

|

a1c0 |

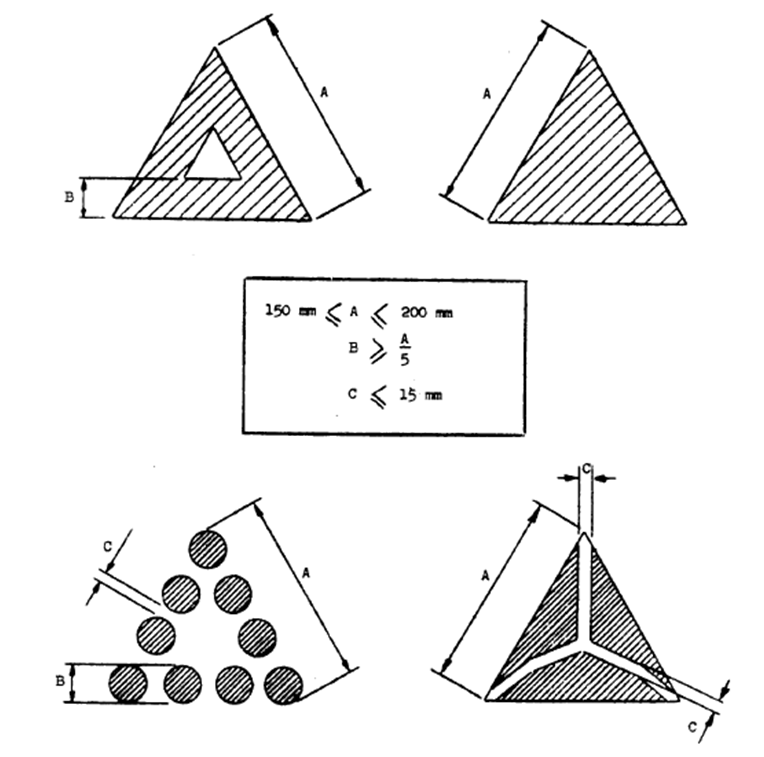

| A5 2. | Shape and dimensions of retro-reflecting devices in Classes IIIA and IIIB (see appendix to this annex) | a0c0 |

| A5 2.1. | The illuminating surfaces of retro-reflecting devices in Classes IIIA and IIIB must have the shape or an equilateral triangle. If the word "TOP" is inscribed in one corner, the apex of that corner must be directed upwards. | a0c0 |

| A5 2.2. | The illuminating surface may or may not have at its centre a triangular, non-retro-reflecting area, with sides parallel to those of the outer triangle. | a0c0 |

| A5 2.3. | The illuminating surface may or may not be continuous. In any case, the shortest distance between two adjacent retro-reflecting optical units must not exceed 15 mm. | a0c0 |

| A5 2.4. | The illuminating surface of a retro-reflecting device shall be considered to be continuous if the edges of the illuminating surfaces of adjacent separate optical units are parallel and if the said optical units are evenly distributed over the whole solid surface of the triangle. | a0c0 |

| A5 2.5. | If the illuminated surface is not continuous, the number of separate retro-reflecting optical units including the corner units shall not be less than four on each side of the triangle. | a0c0 |

| A5 2.5.1. | The separate retro-reflecting optical units shall not be replaceable unless they consist of approved retro-reflecting devices in Class IA. | a0c0 |

| A5 2.6. | The outside edges of the illuminating surfaces of triangular retro-reflecting devices in Classes IIIA and IIIB shall be between 150 and 200 mm long. In the case of devices of hollow-triangle type, the width of the sides, measured at right angles to the latter, shall be equal to at least 20 per cent of the effective length between the extremities of the illuminating surface. | a0c0 |

| A5 3. | Shape and dimensions of retro-reflecting devices in Class IVA | a0c0 |

| A5 3.1. |

The shape of the light emitting surfaces |

a1c0 |

| A5 3.2. |

The light emitting surface of the retro-reflecting device must be at least 25 cm2. |

a0c0 |

| A5 4. | Compliance with the above specifications shall be verified by visual inspection. | a0c0 |

| A5 |

|

a0c0 |

| A5 |

|

a0c0 |

| A5 |

|

a0c0 |

| A5 | Note: These sketches are for illustration purposes only. | a0c0 |

| A6 |

|

a0c0 |

| A6 |

|

a0c0 |

| A6 1. | These specifications shall apply only to clear, red or amber retro-reflecting devices. | a0c0 |

| A6 1.1. | Retro-reflecting devices may consist of a combined retro-reflecting optical unit and filter, which must be so designed that they cannot be separated under normal conditions of use. | a0c0 |

| A6 1.2. | The colouring of retro-reflecting optical units and filters by means of paint or varnish is not permitted. | a0c0 |

| A6 2. |

When the retro-reflecting device is illuminated by CIE standard illuminant A, with an angle of divergence of 1/3 degrees and an illumination angle of V = H = 0 degree, or, if this produces a colourless surface reflection, an angle V = +/- 5 degrees, H = 0 degree, the trichromatic coordinates of the reflected luminous flux must be within the limits according to paragraph 2.30. of Regulation No. 48. |

a0c0 |

| A6 3. | Clear retro-reflecting devices must not produce a selective reflection, that is to say, the trichromatic coordinates "x" and "y" of the standard illuminant "A" used to illuminate the retro-reflecting device must not undergo a change of more than 0.01 after reflection by the retro-reflecting device. | a0c0 |

| A7 |

|

a0c0 |

| A7 |

|

a0c0 |

| A7 1. |

When applying for approval, the applicant shall specify one or more or a range of axis of reference, corresponding to the illumination angle V = H = 0° in the table of coefficients of luminous intensity (CIL). |

a0c0 |

| A7 | In the case where more than one or a range of different axis of reference are specified by the manufacturer, the photometric measurements shall be repeated making reference each time to a different axis of reference or to the extreme axis of reference of the range specified by the manufacturer. | a0c0 |

| A7 2. | For photometric measurements, only the illuminating surface defined by the planes contiguous to the outermost parts of the optical system of the retro-reflecting device as indicated by the manufacturer and contained within a circle of 200 mm diameter for Class IA or IB shall be considered, and the illuminating surface itself shall be limited to 100 cm2 though the surfaces of the retro-reflecting optical units need not necessarily attain this area. The manufacturer shall specify the perimeter of the area to be used. In the case of Class IIIA, Class IIIB and Class IVA, the whole of the illuminating surfaces shall be considered without limitation as to size. | a0c0 |

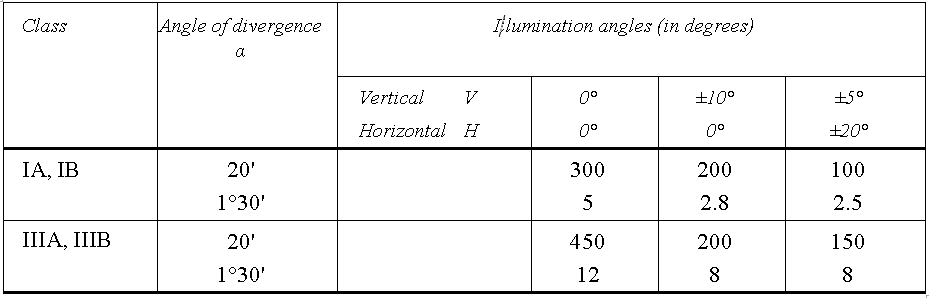

| A7 3. | CIL values | a0c0 |

| A7 3.1. | Class IA, Class IB, Class IIIA and Class IIIB | a0c0 |

| A7 3.1.1. | The CIL values for red retro-reflecting devices must be at least equal to those in the table below, expressed in millicandelas per lux, for the angles of divergence and illumination shown. | a0c0 |

| A7 |

|

a0c0 |

| A7 | CIL values lower than those shown in the last two columns of the above table are not permissible within the solid angle having the reference centre as its apex and bounded by the planes intersecting along the following lines: | a0c0 |

| A7 |

(V = ±10°, H = 0°) (V = ±5°, H = ±20°). |

a0c0 |

| A7 3.1.2. | CIL values for amber retro-reflecting devices in Class IA or IB must be at least equal to those in the table of paragraph 3.1.1. above multiplied by the coefficient 2.5. | a0c0 |

| A7 3.1.3. | CIL values for colourless retro-reflecting devices in Class IA or IB must be at least equal to those in the table of paragraph 3.1.1. above multiplied by the coefficient 4. | a0c0 |

| A7 3.2. |

However, in the case where a retro-reflecting device of Class IA, Class IB, Class IIIA or Class IIIB is intended to be installed with its H plane at a mounting height less than 750 mm above the ground, the CIL values are verified only up to an angle of 5° downwards. |

a0c0 |

| A7 3.3. | For devices of Class IVA the CIL values must be at least equal to those in the table below, expressed in millicandelas per lux, for the angles of divergence and illumination shown. | a0c0 |

| A7 |

|

a0c0 |

| A7 3.4. |

However, in the case where a retro-reflecting device of Class IVA is intended to be installed with its H plane at a mounting height less than 750 mm above the ground, the CIL values are verified only up to an angle of 5° downwards. |

a0c0 |

| A7 4. |

When the CIL of a retro-reflecting device is measured for an angle β of V = H = 0°, it shall be ascertained whether any mirror effect is produced by slightly turning the device. If there is any such effect, a reading shall be taken with an angle β of V = ±5°, H = 0°. The position adopted shall be that corresponding to the minimum CIL for one of these positions. |

a0c0 |

| A7 4.1. |

With an illumination angle β of V = H = 0°, or the angle specified in paragraph 4. above, and an angle of divergence of 20', retro-reflecting devices which are not marked "TOP" shall be rotated about their axes of reference to the position of minimum CIL, which must conform to the value specified in paragraph 3. above. When the CIL is measured for the other angles of illumination and divergence, the retro-reflecting device shall be placed in the position corresponding to this value of ε. If the specified values are not attained, the device may be rotated about its axis of reference ±5° from that position. |

a0c0 |

| A7 4.2. |

With an illumination angle β of V = H = 0°, or the angle specified in paragraph 4. above, and an angle of divergence of 20', retro-reflecting devices marked "TOP" shall be rotated about their axes ±5°. The CIL must not fall below the prescribed value in any position assumed by the device during this rotation. |

a0c0 |

| A7 4.3. |

If for the direction V = H = 0°, and for ε = 0° the CIL exceeds the specified value by 50 per cent or more, all measurements for all angles of illumination and divergence shall be made for ε = 0°. |

a0c0 |

| A8 |

|

a0c0 |

| A8 |

|

a0c0 |

| A8 1. | Resistance to water and dirt penetration | a0c0 |

| A8 1.1. | Water submersion test | a0c0 |

| A8 1.1.1. |

Retro-reflecting devices whether part of a lamp or not, shall be stripped of all removable parts and immersed for 10 minutes in water at a temperature of 50 ± 5 °C, the highest point of the upper part of the illuminating surface being 20 mm below the surface of the water. This test shall be repeated after turning the retro-reflecting device through 180°, so that the illuminating surface is at the bottom and the rear face is covered by about 20 mm of water. These optical units shall then be immediately immersed in the same conditions in water at a temperature of 25 ± 5 °C. |

a0c0 |

| A8 1.1.2. | No water shall penetrate to the reflecting surface of the retro-reflecting optical unit. If visual inspection clearly reveals the presence of water, the device shall not be considered to have passed the test. | a0c0 |

| A8 1.1.3. |

If visual inspection does not reveal the presence of water or in case of doubt, the CIL shall be measured by the method described in Annex 4, paragraph 3.2., or Annex 14, paragraph 4.2., the retro-reflecting device being first lightly shaken to remove excess water from the outside. |

a0c0 |

| A8 1.2. | Alternative test procedure for Classes IB and IIIB devices | a0c0 |

| A8 | As an alternative, at the request of the manufacturer, the following test (moisture and dust test) shall be applied instead of the submersion-test specified in paragraph 1.1. above. | a0c0 |

| A8 1.2.1. | Moisture test | a0c0 |

| A8 | The test evaluates the ability of the sample device to resist moisture penetration from a water spray and determines the drainage capability of those devices with drain holes or other exposed openings in the device. | a0c0 |

| A8 1.2.1.1. | Water spray test equipment | a0c0 |

| A8 | A water spray cabinet with the following characteristics shall be used: | a0c0 |

| A8 1.2.1.1.1. | Cabinet | a0c0 |

| A8 |

The cabinet shall be equipped with a nozzle(s) which provides a solid cone water spray of sufficient angle to completely cover the sample device. The centreline of the nozzle(s) shall be directed downward at an angle of 45°± 5° to the vertical axis of a rotating test platform. |

a0c0 |

| A8 1.2.1.1.2. | Rotating test platform | a0c0 |

| A8 | The rotating test platform shall have a minimum diameter of 140 mm and rotate about a vertical axis in the centre of the cabinet. | a0c0 |

| A8 1.2.1.1.3. | Precipitation rate | a0c0 |

| A8 | The precipitation rate of the water spray at the device shall be 2.5 (+1.6/-0) mm/min as measured with a vertical cylindrical collector centred on the vertical axis of the rotating test platform. The height of the collector shall be 100 mm and the inside diameter shall be a minimum of 140 mm. | a0c0 |

| A8 1.2.1.2. | Water spray test procedure | a0c0 |

| A8 | A sample device mounted on a test fixture, with initial CIL measured and recorded shall be subjected to a water spray as follows: | a0c0 |

| A8 1.2.1.2.1. | Device openings | a0c0 |

| A8 | All drain holes and other openings shall remain open. Drain wicks, when used, shall be tested in the device. | a0c0 |

| A8 1.2.1.2.2. | Rotational speed | a0c0 |

| A8 |

The device shall be rotated about its vertical axis at a rate of 4.0 ± 0.5 min -1. |

a0c0 |

| A8 1.2.1.2.3. |

If the retro-reflector is reciprocally incorporated or grouped with signalling or lighting functions, these functions shall be operated at design voltage according to a cycle of 5 min ON (in flashing mode, where appropriate), 55 min OFF. |

a0c0 |

| A8 1.2.1.2.4. | Test duration | a0c0 |

| A8 | The water spray test shall last 12 hours (12 cycles of 5/55 min). | a0c0 |

| A8 1.2.1.2.5. | Drain period | a0c0 |

| A8 | The rotation and the water spray shall be turned OFF and the device allowed to drain for 1 hour with the cabinet door closed. | a0c0 |

| A8 1.2.1.2.6. | Sample evaluation | a0c0 |

| A8 | Upon completion of the drain period. The interior of the device shall be observed for moisture accumulation. No standing pool of water shall be allowed to be formed, or which can be formed by tapping or tilting the device. The CIL shall be measured according to the method specified in Annex 4 paragraph 3.2. after having dried the exterior of the device with a dry cotton cloth. | a0c0 |

| A8 1.2.2. | Dust exposure test | a0c0 |

| A8 | This test evaluates the ability of the sample device to resist dust penetration which could significantly affect the photometric output of the retro-reflector. | a0c0 |

| A8 1.2.2.1. | Dust exposure test equipment | a0c0 |

| A8 | The following equipment shall be used to test for dust exposure: | a0c0 |

| A8 1.2.2.1.1. | Dust exposure test chamber | a0c0 |

| A8 | The interior of the test chamber shall be cubical in shape in size 0.9 to 1.5 m per side. The bottom may be "hopper shaped" to aid in collecting the dust. The internal chamber volume, not including a "hopper shaped" bottom shall be 2 m3 maximum and shall be charged with 3 to 5 kg of the test dust. The chamber shall have the capability of agitating the test dust by means of compressed air or blower fans in such a way that the dust is diffused throughout the chamber. | a0c0 |

| A8 1.2.2.1.2. | The dust | a0c0 |

| A8 | The test dust used shall be fine powdered cement in accordance with standard ASTM C 150-84.[*] | a0c0 |

|

A8 |

|

a0c0 |

| A8 1.2.2.2. | Dust exposure test procedure | a0c0 |

| A8 | A sample device, mounted on a test fixture, with the initial CIL measured and recorded, shall be exposed to dust as follows: | a0c0 |

| A8 1.2.2.2.1. | Device openings | a0c0 |

| A8 | All drain holes and other openings shall remain open. Drain wicks, when used, shall be tested in the device. | a0c0 |

| A8 1.2.2.2.2. | Dust exposure | a0c0 |

| A8 |

The mounted device shall be placed in the dust chamber no closer than 150 mm from a wall. Devices with a length exceeding 600 mm shall be horizontally centred in the test chamber. The test dust shall be agitated as completely as possible by compressed air or blower(s) at intervals of 15 min for a period of 2 to 15 s for the duration of 5 hours. The dust shall be allowed to settle between the agitation periods. |

a0c0 |

| A8 1.2.2.2.3. | Measured sample evaluation | a0c0 |

| A8 | Upon completion of the dust exposure test, the exterior of the device shall be cleaned and dried with a dry cotton cloth and the CIL measured according to the method specified in Annex 4, paragraph 3.2. | a0c0 |

| A8 2. | Resistance to corrosion | a0c0 |

| A8 2.1. | Retro-reflecting devices must be so designed that they retain the prescribed photometric and colorimetric characteristics despite the humidity and corrosive influences to which they are normally exposed. The resistance of the front surface to tarnishing and of the protection of the rear face to deterioration shall be checked, particularly when an essential metal component seems liable to be attacked. | a0c0 |

| A8 2.2. | The retro-reflecting device, or the lamp if the device is combined with a light, shall be stripped of all removable parts and subjected to the action of a saline mist for a period of 50 hours, comprising two periods of exposure of 24 hours each, separated by an interval of two hours during which the sample is allowed to dry. | a0c0 |

| A8 2.3. |

The saline mist shall be produced by atomizing, at a temperature of 35 °C ± 2 °C, a saline solution obtained by dissolving 20 ± 2 parts by weight of sodium chloride in 80 parts of distilled water containing not more than 0.02 per cent of impurities. |

a0c0 |

| A8 2.4. | Immediately after completion of the test, the sample must not show signs of excessive corrosion liable to impair the efficiency of the device. | a0c0 |

| A8 3. | Resistance to fuels | a0c0 |

| A8 | The outer surface of the retro-reflecting device and, in particular, of the illuminating surface, shall be lightly wiped with a cotton cloth soaked in a mixture of 70 vol. per cent of n-heptane and 30 vol. per cent of toluol. After about five minutes, the surface shall be inspected visually. It must not show any apparent surface changes, except that slight surface cracks will not be objected to. | a0c0 |

| A8 4. | Resistance to lubricating oils | a0c0 |

| A8 | The outer surface of the retro-reflecting device and, in particular, the illuminating surface, shall be lightly wiped with a cotton cloth soaked in a detergent lubricating oil. After about 5 minutes, the surface shall be cleaned. The CIL shall then be measured (Annex 4, paragraph 3.2. or Annex 14, paragraph 4.2.). | a0c0 |

| A8 5. | Resistance of the accessible rear face of mirror-backed retro-reflecting devices | a0c0 |

| A8 5.1. | After having brushed the rear face of the retro-reflecting device with a hard nylon brush, a cotton cloth soaked in the mixture, defined in paragraph 3. Above shall be applied to the said rear face for one minute. The cotton cloth is then removed and the retro-reflecting device left to dry. | a0c0 |

| A8 5.2. | As soon as evaporation is completed, an abrasion test shall be made by brushing the rear face with the same nylon brush as before. | a0c0 |

| A8 5.3. | The CIL shall then be measured (Annex 4, paragraph 3.2. or Annex 14, paragraph 4.2.) after the whole surface of the mirror-backed rear face has been covered with Indian ink. | a0c0 |

| A9 |

|

a0c0 |

| A9 |

|

a0c0 |

|

A9 |

|

a0c0 |

| A9 1. | The Type Approval Authority which granted approval shall have the right to check the stability in time of the optical properties of a type of retro-reflecting device in service. | a0c0 |

| A9 2. | The competent authorities of countries other than the country in which approval was granted may carry out similar checks in their territory. If a type of retro-reflector in use exhibits a systematic defect, the said authorities shall transmit any components removed for examination to the Type Approval Authority which granted approval, with a request for its opinion. | a0c0 |

| A9 3. | In the absence of other criteria, the concept of "systematic defect" of a type of retro-reflector in use shall be interpreted in conformity with the intention of paragraph 6.1. of this Regulation. | a0c0 |

| A10 |

|

a0c0 |

| A10 |

|

a0c0 |

| A10 1. |

The retro-reflecting device shall be kept for 48 consecutive hours in a dry atmosphere at a temperature of 65 °C ± 2 °C. |

a0c0 |

| A10 2. | After this test, no cracking or appreciable distortion of the retro-reflecting device and, in particular, of its optical component must be visible. | a0c0 |

| A11 |

|

a0c0 |

| A11 |

|

a0c0 |

|

A11 |

|

a0c0 |

| A11 1. | The Type Approval Authority which granted approval shall have the right to check the colour-fastness of a type of retro-reflecting device in service. | a0c0 |

| A11 2. | The competent authorities of countries other than the country in which approval was granted may carry out similar checks in their territory. If a type of retro-reflector in use exhibits a systematic defect, the said authorities shall transmit any components removed for examination to the Type Approval Authority which granted approval, with a request for its opinion. | a0c0 |

| A11 3. | In the absence of other criteria, the concept "systematic defect" of a type of retro-reflector in use shall be interpreted in conformity with the intention of paragraph 9.1. of this Regulation. | a0c0 |

| A12 |

|

a0c0 |

| A12 |

|

a0c0 |

| A12 |

|

a0c0 |

| A12 |

|

a0c0 |

| A13 |

|

a0c0 |

| A13 |

|

a0c0 |

| A13 1. | The retro-reflecting device shall be mounted in a manner similar to the way in which it is mounted on the vehicle, but with the lens faced horizontal and directed upwards. | a0c0 |

| A13 2. | Drop a 13 mm diameter polished solid steel ball, once, vertically onto the central part of the lens from a height of 0.76 m. The ball may be guided but not restricted in free fall. | a0c0 |

| A13 3. | When a retro-reflecting device is tested at room temperature with this method, the lens shall not crack. | a0c0 |

| A14 |

|

a0c0 |

| A14 |

|

a0c0 |

| A14 1. | The applicant shall submit for approval ten samples which shall be tested in the chronological order indicated in Annex 15. | a0c0 |

| A14 2. |

After verification of the specifications in paragraphs 6.1. to 6.5. of this Regulation and the specifications of shape and dimensions (Annex 5), the ten samples shall be subjected to the heat resistance test (Annex 10) and one hour minimum after this test examined as to their colorimetric characteristics and CIL (Annex 7) for an angle of divergence of 20' and an illumination angle V = H = 0° or, if necessary, in the positions defined in Annex 7. The two retro-reflecting devices giving the minimum and maximum values shall then be fully tested as shown in Annex 7. These two samples shall be kept by the laboratories for any further checks which may be found necessary. |

a0c0 |

| A14 3. | Four samples out of the remaining eight samples shall be selected at random and divided into two groups of two in each group. | a0c0 |

| A14 | First group: | a0c0 |

| A14 | The two samples shall be subjected successively to the water-penetration resistance test (Annex 8, paragraph 1.) and then, if this test is satisfactory, to the tests for resistance to fuels and lubricating oils (Annex 8, paragraphs 3. and 4.). | a0c0 |

| A14 | Second group: | a0c0 |

| A14 |

The two samples shall, if relevant, be subjected to the corrosion test (Annex 8, paragraph 2.), and then to the abrasive-strength test of the rear face of the retro-reflecting device (Annex 8, paragraph 5.). These two samples shall also be subjected to the impact test (Annex 13). |

a0c0 |

| A14 4. | After undergoing the tests referred to in the above paragraph, the retro-reflecting devices in each group must have: | a0c0 |

| A14 4.1. | A colour which satisfies the conditions laid down in Annex 6. This shall be verified by a qualitative method and, in case of doubt, confirmed by a quantitative method; | a0c0 |

| A14 4.2. |

A CIL which satisfies the conditions laid down in Annex 7. Verification shall be performed only for an angle of divergence of 20' and an illumination angle of V = H = 0° or, if necessary, in the positions specified in Annex 7. |

a0c0 |

| A14 5. | The four remaining samples can be utilized, if necessary, for any other purpose. | a0c0 |

| A15 |

|

a0c0 |

| A15 |

|

a0c0 |

| A15 |

|

a0c0 |

| A15 |

|

a0c0 |

| A16 |

|

a0c0 |

| A16 |

|

a0c0 |

| A16 |

Retro-reflecting devices of Classes IB and IIIB shall be tested according to the test procedures specified in Annex 4, following the chronological order of tests given in Annex 12, with the exception of the test according to Annex 8, paragraph 1., which for Classes IB and IIIB devices may be replaced by the test specified in Annex 8, paragraph 1.2. |

a0c0 |

| A17 |

|

a0c0 |

| A17 |

|

a0c0 |

| A17 1. | General | a0c0 |

| A17 1.1. | The conformity requirements shall be considered satisfied from a mechanical and geometric standpoint, if the differences do not exceed inevitable manufacturing deviations within the requirements of this Regulation. | a0c0 |

| A17 1.2. | With respect to photometric performances, the conformity of mass-produced retro-reflectors shall not be contested if, when testing photometric performances of any retro-reflector chosen at random no measured value deviates unfavourably by more than 20 per cent from the minimum values prescribed in this Regulation. | a0c0 |

| A17 1.3. | The chromaticity coordinates shall be complied with. | a0c0 |

| A17 2. | Minimum requirements for verification of conformity by the manufacturer | a0c0 |

| A17 | For each type of retro-reflector the holder of the approval mark shall carry out at least the following tests, at appropriate intervals. The tests shall be carried out in accordance with the provisions of this Regulation. | a0c0 |

| A17 | If any sampling shows non-conformity with regard to the type of test concerned, further samples shall be taken and tested. The manufacturer shall take steps to ensure the conformity of the production concerned. | a0c0 |

| A17 2.1. | Nature of tests | a0c0 |

| A17 | Tests of conformity in this Regulation shall cover the photometric and colorimetric characteristics and the resistance to penetration of water. | a0c0 |

| A17 2.2. | Methods used in tests | a0c0 |

| A17 2.2.1. | Tests shall generally be carried out in accordance with the methods set out in this Regulation. | a0c0 |

| A17 2.2.2. | In any test of conformity carried out by the manufacturer, equivalent methods may be used with the consent of the Type Approval Authority. The manufacturer is responsible for proving that the applied methods are equivalent to those laid down in this Regulation. | a0c0 |

| A17 2.2.3. | The application of paragraphs 2.2.1. and 2.2.2. above requires regular calibration of test apparatus and its correlation with measurements made by a competent authority. | a0c0 |

| A17 2.2.4. | In all cases the reference methods shall be those of this Regulation, particularly for the purpose of administrative verification and sampling. | a0c0 |

| A17 2.3. | Nature of sampling | a0c0 |

| A17 | Samples of retro-reflectors shall be selected at random from the production of a uniform batch. A uniform batch means a set of retro-reflectors of the same type, defined according to the production methods of the manufacturer. | a0c0 |

| A17 | The assessment shall in general cover series production from individual factories. However, a manufacturer may group together records concerning the same type from several factories, provided these operate under the same quality system and quality management. | a0c0 |

| A17 2.4. | Measured and recorded photometric characteristics | a0c0 |

| A17 | The sampled retro-reflector shall be subjected to photometric measurements at the points and the chromaticity coordinates provided for in the Regulation. | a0c0 |

| A17 2.5. | Criteria governing acceptability | a0c0 |

| A17 | The manufacturer is responsible for carrying out a statistical study of the test results and for defining, in agreement with the Type Approval Authority, criteria governing the acceptability of his products in order to meet the specifications laid down for the verification of conformity of products in paragraph 8.1. of this Regulation. | a0c0 |

| A17 | The criteria governing the acceptability shall be such that, with a confidence level of 95 per cent, the minimum probability of passing a spot check in accordance with Annex 18 (first sampling) would be 0.95. | a0c0 |

| A18 |

|

a0c0 |

| A18 |

|

a0c0 |

| A18 1. | General | a0c0 |

| A18 1.1. | The conformity requirements shall be considered satisfied from a mechanical and a geometric standpoint, in accordance with the requirements of this Regulation, if any, if the differences do not exceed inevitable manufacturing deviations. | a0c0 |

| A18 1.2. | With respect to photometric performance, the conformity of mass-produced retro-reflectors shall not be contested if, when testing photometric performances of any retro-reflector chosen at random: | a0c0 |

| A18 1.2.1. | No measured value deviates unfavourably by more than 20 per cent from the minimum values prescribed in this Regulation. | a0c0 |

| A18 1.2.2. | Retro-reflectors with apparent defects are disregarded. | a0c0 |

| A18 1.3. | The chromaticity coordinates shall be complied with. | a0c0 |

| A18 2. |

First sampling |

a3c0 |

| A18 | In the first sampling four retro-reflectors are selected at random. The first sample of two is marked A, the second sample of two is marked B. | a3c0 |

| A18 2.1. |

In the case, that the deviation of both retro-reflectors of sample A is not more than 0 per cent, the measurement can be closed. |

a3c0 |

| A18 2.1.1. |

|

a3c0 |

| A18 2.1.1.1. |

|

a3c0 |

| A18 2.1.1.2. |

|

a3c0 |

| A18 2.2. |

The manufacturer shall be requested to bring his production in line with the requirements (alignment) and a repeated sampling according to paragraph 3. below shall be carried out within two months' time after the notification. The samples A and B shall be retained by the Technical Service until the entire CoP process is finished. |

a3c0 |

| A18 2.2.1. |

|

a3c0 |

| A18 2.2.1.1. |

|

a3c0 |

| A18 2.2.1.2. |

|

a3c0 |

| A18 2.3. |

|

a3c0 |

| A18 2.3.1. |

|

a3c0 |

| A18 2.3.2. |

|

a3c0 |

| A18 3. |

A sample of four retro-reflectors is selected at random from stock manufactured after alignment. The first sample of two is marked C, the second sample of two is marked D. |

a3c0 |

| A18 3.1. |

In the case, that the deviation of both retro-reflectors of sample C is not more than 0 per cent, the measurement can be closed. |

a3c0 |

| A18 3.1.1. |

|

a3c0 |

| A18 3.1.1.1. |

|

a3c0 |

| A18 3.1.1.2. |

|

a3c0 |

| A18 3.2. |

|

a3c0 |

| A18 3.2.1. |

The manufacturer shall be requested again to bring his production in line with the requirements (alignment). A second repeated sampling according to paragraph 4. below shall be carried out within two months' time after the notification. The samples C and D shall be retained by the Technical Service until the entire CoP process is finished. |

a3c0 |

| A18 3.2.1.1. |

|

a3c0 |

|

A18 |

In this case the approval shall be withdrawn and paragraph 5. below shall be applied. |

a3c0 |

| A18 3.3.1. |

|

a3c0 |

| A18 3.3.2. |

|

a3c0 |

|

A18 |

A sample of four retro-reflectors is selected at random from stock manufactured after alignment. The first sample of two is marked E, the second sample of two is marked F. |

a3c0 |

|

A18 |

|

a3c0 |

|

A18 |

In this case the approval shall be withdrawn and paragraph 5 below shall be applied. |

a3c0 |

|

A18 |

Approval shall be withdrawn according to paragraph 9. of this Regulation. |

a3c0 |

|

A18 |

Resistance to penetration of water With respect to the verification of the resistance to penetration of water, the following procedure shall be applied: One of the retro-reflectors of sample A, after sampling procedure in The retro-reflectors shall be considered as acceptable if the test has been passed. However, if the test on sample A is not complied with, the two retro reflectors of sample B shall be subjected to the same procedure and both shall pass the test. |

a3c0 |

| A18 |

|

a3c0 |