| ... | 1. Scope | a0c0 |

| ... | 2. Definitions | a0c0 |

| ... | 3. Application for approval | a0c0 |

| ... | 4. Markings | a0c0 |

| ... | 5. Approval | a0c0 |

| ... | 6. Specifications | a0c0 |

| ... | 7. Modifications of the type of pneumatic tyre and extension of approval | a0c0 |

| ... | 8. Conformity of production | a0c0 |

| ... | 9. Penalties for non-conformity of production | a0c0 |

| ... | 10. Production definitively discontinued | a0c0 |

| ... | 11. Names and addresses of Technical Services responsible for conducting approval tests of Type Approval Authorities | a0c0 |

| ... | 12. Transitional provisions | a0c0 |

| ... | Annexes | a0c0 |

| ... | 1. Communication | a0c0 |

| ... |

2. Arrangements of approval marks |

a6c0 |

| ... |

Appendix 1 - Example of separate Regulation No. 117 approval marks |

a6c0 |

| ... | a6c0 | |

| ... | a6c0 | |

| ... | Appendix 4 - Extensions to combine approvals issued in accordance with Regulation No. 117 | a0c0 |

| ... | 3. Coast-by test method for measuring tyre-rolling sound emission | a0c0 |

| ... | Appendix 1 - Test report | a0c0 |

| ... | 4. Specifications for the test site | a0c0 |

| ... | a6c0 | |

| ... | Appendix 1 - Test reports examples of wet grip index | a0c0 |

| ... | 6. Test procedure for measuring rolling resistance | a0c0 |

| ... | Appendix 1 -Test equipment tolerances | a0c0 |

| ... | a6c0 | |

| ... | Appendix 3 - Test report and test data (Rolling resistance) | a0c0 |

| ... | Appendix 4 -Tyre standards organizations | a0c0 |

| ... | Appendix 5 - Deceleration method: Measurements and data processing for deceleration value obtaining in differential form dω/dt | a0c0 |

| ... | 7. Procedures for snow performance testing relative to snow tyre for use in severe snow conditions | a0c0 |

| ... | a6c0 | |

| ... | Appendix 2 - Test reports and test data for C1 and C2 tyres | a0c0 |

| ... | Appendix 3 - Test reports and test data for C3 tyres | a0c0 |

| ... |

8. Procedures for ice performance testing relative to ice grip tyre of class C1 |

a6c0 |

| ... | a6c0 | |

| ... | a6c0 | |

| 1. |

|

a0c0 |

| 1.1. |

This Regulation applies to new pneumatic tyres |

a1c0 |

|

|

|

a1c0 |

| 1.1.1. | Tyres designed as "Temporary use spare tyres" and marked "Temporary use only"; | a0c0 |

| 1.1.2. | Tyres having a nominal rim diameter code ≤ 10 (or ≤ 254 mm) or ≥ 25 (or ≥ 635 mm); | a0c0 |

| 1.1.3. | Tyres designed for competitions; | a0c0 |

| 1.1.4. | Tyres intended to be fitted to road vehicles of categories other than M, N and O;[1] | a0c0 |

| 1.1.5. | Tyres fitted with additional devices to improve traction properties (e.g. studded tyres); | a0c0 |

| 1.1.6. |

Tyres with a speed |

a6c0 |

| 1.1.7. | Tyres designed only to be fitted to vehicles registered for the first time before 1 October 1990. | a0c0 |

| 1.1.8. | Professional off-road tyres. | a0c0 |

| 1.2. | Contracting Parties shall issue or accept approvals to rolling sound and/or wet adhesion and/or rolling resistance. | a0c0 |

|

|

|

a0c0 |

| 2. |

|

a0c0 |

| ... | For the purpose of this Regulation, in addition to the definitions contained in Regulations Nos. 30 and 54, the following definitions apply. | a0c0 |

| 2.1. |

"Type of tyre" means |

a2c0 |

| ... | (a) The manufacturer's name; | a0c0 |

| ... |

(b) The tyre class (see paragraph 2.6. below); |

a6c0 |

| ... | (c) The tyre structure; | a0c0 |

| ... | (d) The category of use: normal tyre, snow tyre and special use tyre; | a0c0 |

| ... | (e) Whether tyre for use in severe snow conditions or not; | a3c0 |

| ... |

(f) For class C1 tyres, whether ice grip tyre or not; |

a6c0 |

| ... | [DEL] | a3c0 |

| ... | [DEL] | a3c0 |

| ... |

(g) For Classes C2 and C3 tyres, whether traction tyre or not: |

a6c0 |

| ... | [DEL] | a3c0 |

| ... | [DEL] | a3c0 |

| ... |

(h) The tread pattern (see paragraph 3.2.1. of this Regulation). |

a6c0 |

| 2.2. |

|

a1c0 |

| 2.3. |

"Brand name/trademark" means the identification of the brand or trademark as defined by the tyre manufacturer and marked on the sidewall(s) of the tyre. The brand name/trademark may be the same as that of the Manufacturer. |

a6c0 |

|

|

|

a1c0 |

|

2. |

"Rolling sound emission" means the sound emitted from the contact between the tyres in motion and the road surface. | a1c0 |

|

2. |

"Tyre class" means one of the following groupings: | a1c0 |

|

2. |

Class C1 tyres: Tyres conforming to Regulation No. 30; | a1c0 |

|

2. |

Class C2 tyres: Tyres conforming to Regulation No. 54 and identified by a load capacity index in single formation lower or equal to 121 and a speed category symbol higher or equal to "N"; | a1c0 |

|

2. |

Class C3 tyres: Tyres conforming to Regulation No. 54 and identified by: | a1c0 |

| ... | (a) A load capacity index in single formation higher or equal to 122; or | a0c0 |

| ... | (b) A load capacity index in single formation lower or equal to 121 and a speed category symbol lower or equal to "M". | a0c0 |

| 2.7. |

"Representative tyre size" means the tyre size which is submitted to the test described in Annex 3 to this Regulation with regard to rolling sound emissions, or Annex 5 for adhesion on wet surfaces or Annex 6 for rolling resistance to assess the conformity for the type approval of the type of tyre, or Annex 7 for measuring snow performance, or Annex 8 for measuring ice performance." |

a6c0 |

|

2. |

"Temporary-use spare tyre" means a tyre different from a tyre intended to be fitted to any vehicle for normal driving conditions; but intended only for temporary use under restricted driving conditions. | a1c0 |

|

2. |

"Tyres designed for competition" means tyres intended to be fitted to vehicles involved in motor sport competition and not intended for non-competitive on-road use. | a1c0 |

|

2. |

"Normal tyre" means a tyre intended for normal on-road use. | a1c0 |

|

2. |

"Reinforced tyre" or "extra load tyre" of Class C1 means a |

a1c0 |

|

|

|

a0c0 |

|

2. |

"Traction tyre" means a tyre in Class C2 or C3 bearing the inscription TRACTION and intended to be fitted primarily to the drive axle(s) of a vehicle to maximize force transmission in various circumstances. | a1c0 |

|

2. |

"Snow tyre" means a tyre whose tread pattern, tread compound or structure is primarily designed to achieve in snow conditions a performance better than that of a normal tyre with regard to its ability to initiate or maintain vehicle motion. | a1c0 |

| 2.13.1. |

"Snow tyre for use in severe snow conditions" means a snow tyre whose tread pattern, tread compound or structure is specifically designed to be used in severe snow conditions and that fulfils the requirements of paragraphs 6.4. and 6.4.1. of this Regulation." |

a6c0 |

|

|

"Ice grip tyre" means a class C1 snow tyre for use in severe snow conditions that is additionally designed to be used on road surfaces covered with ice and that fulfils the requirements of paragraph 6.4.2. of this Regulation." |

a6c0 |

|

2. |

"Special use tyre" means a tyre intended for mixed use both on- and off-road or for other special duty. These tyres are primarily designed to initiate and maintain the vehicle in motion in off-road conditions. | a1c0 |

|

2. |

"Professional off-road tyre" is a special use tyre primarily used for service in severe off-road conditions. | a1c0 |

|

2. |

"Tread depth" means the depth of the principal grooves. | a1c0 |

|

2. |

"Principal grooves" means the wide circumferential grooves positioned in the central zone of the tyre tread, which, in the case of passenger and light truck (commercial) tyres, have the treadwear indicators located in the base. | a1c0 |

|

2. |

"Void to fill ratio" means the ratio between the area of voids in a reference surface and the area of this reference surface calculated from the mould drawing. | a1c0 |

| 2.18. |

"Standard Reference Test Tyre" |

a5c0 |

| ... |

(a) E1136 - 17 [DEL] for the size P195/75R14 and referred to as "SRTT14", |

a3c0 |

| ... |

(b) F2493 – 20 for the size P225/60R16 and referred to as "SRTT16", |

a6c0 |

| ... |

(c) F2872 – 16 for the size 225/75R16C and referred to as "SRTT16C", |

a6c0 |

| ... |

(d) F2871 – 16 for the size 245/70R19.5 and referred to as "SRTT19.5", |

a6c0 |

| ... |

(e) F2870 – 16 for the size 315/70R22.5 and referred to as "SRTT22.5". |

a6c0 |

| 2.19. |

Wet grip or snow DEL performance or ice performance measurements - Specific definitions |

a6c0 |

| 2.19.1. |

"Adhesion on wet surfaces" or "wet adhesion" means the relative braking performance, on a wet surface, of a test vehicle equipped with the candidate tyre in comparison to that of the same test vehicle equipped with a Standard Reference Test Tyre (SRTT). |

a6c0 |

| 2.19.2. |

"Candidate tyre" or "candidate tyre set" means a tyre or a tyre set, representative of the type that is submitted for approval in accordance with this Regulation and whose performances are evaluated relative to that of a reference tyre or reference tyre set. |

a6c0 |

|

|

"Reference tyre" or "reference tyre set" means a tyre or a tyre set of Standard Reference Test Tyres as defined in the respective annex. |

a6c0 |

|

2.19. |

"Control tyre" or "control tyre set" means a normal production tyre or a normal production tyre set that is used to establish the wet DEL adhesion level or snow DEL performance level or ice performance level of tyre sizes unable to be fitted to the same vehicle as the DEL reference tyre or reference tyre set – see paragraph 2.2.2.8. of Annex 5, part (B), paragraph 3.4.3. of Annex 7 and paragraph 2.4.5.1.1. of Annex 8 to this Regulation. |

a6c0 |

|

|

"Test tyre" means a candidate tyre, reference tyre or control tyre. |

a6c0 |

|

2.19. |

"Wet grip index" (G) means the dimensionless unit for expressing the wet adhesion level of a candidate tyre relative to that of the applicable DEL SRTT." |

a6c0 |

|

2.19. |

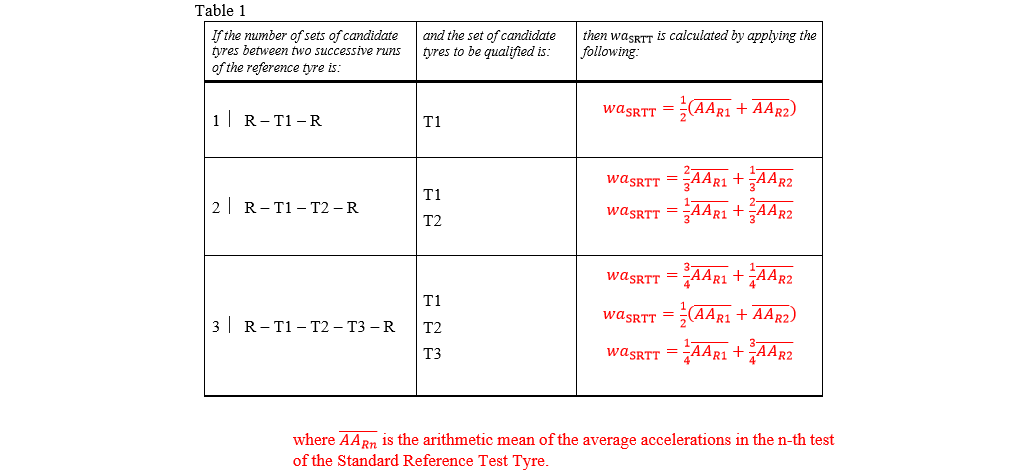

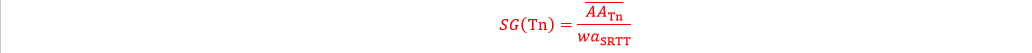

"Snow grip index" (SG) means the dimensionless unit for expressing the snow DEL performance level of a candidate tyre relative to the performance of the applicable SRTT." |

a6c0 |

|

|

"Ice grip index" (GI) means the dimensionless unit for expressing the ice performance level of a candidate tyre relative to the performance of the applicable SRTT. |

a6c0 |

|

2.19. |

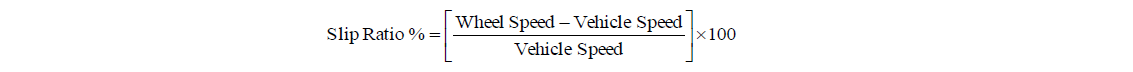

"Peak brake force coefficient ("pbfc")" means the maximum value of the ratio of braking force to vertical load on the tyre prior to wheel lock-up. |

a6c0 |

|

2.19. |

"Mean fully developed deceleration ("mfdd")" means the average deceleration calculated on the basis of the measured distance recorded when decelerating a vehicle between two specified speeds. |

a6c0 |

|

2.19. |

"Coupling (hitch) height" means the height when measured perpendicularly from the centre of the articulation point of the trailer towing coupling or hitch to the ground, when the towing vehicle and trailer are coupled together. The vehicle and trailer shall be standing on level pavement surface in its test mode complete with the appropriate tyre(s) to be used in the particular test. |

a6c0 |

|

|

"Test run" means a single pass of a loaded tyre over a given test surface. |

a6c0 |

|

|

"Braking test" means a series of a specified number of test runs of the same test tyre repeated within a short time frame. |

a6c0 |

|

|

"Traction test" means a series of a specified number of spin-traction test runs of the same tyre repeated within a short time frame. |

a6c0 |

|

|

"Acceleration test" means a series of specified number of traction controlled acceleration test runs of the same tyre repeated within a short timeframe. |

a6c0 |

|

|

"Test cycle" means a series of braking tests, traction tests or acceleration tests that consist of an initial test of the reference tyre or the control tyre, of tests of candidate tyres and/or control tyres and a final test of the same reference tyre or control tyre." |

a6c0 |

|

2. |

Rolling resistance measurement - Specific definitions | a1c0 |

| 2.20.1. |

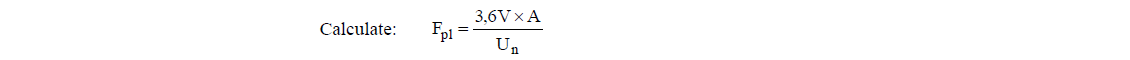

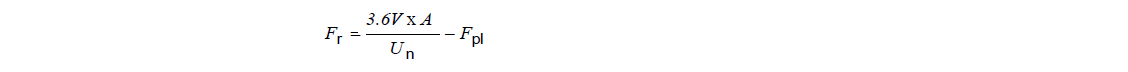

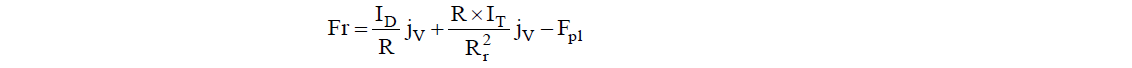

"Rolling resistance (Fr)" |

a6c0 |

| ... | means the loss of energy (or energy consumed) per unit of distance traveled.[3] | a3c0 |

|

|

|

a0c0 |

| 2.20.2. |

Rolling resistance coefficient (Cr) |

a6c0 |

| ... |

Means the ratio of the rolling resistance to the load on the tyre.[4] |

a6c0 |

|

|

|

a0c0 |

| 2.20.3. | "New test tyre" | a3c0 |

| ... |

means a tyre which has not been previously used in a rolling deflected test [DEL] which elevates the tyre's temperature to higher than that generated in rolling resistance tests, and which has not previously been exposed to a temperature above 40 ºC.[5], [6] |

a3c0 |

|

|

|

a0c0 |

|

|

|

a0c0 |

|

2. |

Laboratory control tyre | a1c0 |

| ... |

Means a tyre used by an individual laboratory to control machine behaviour as a function of time.[7] |

a6c0 |

|

|

|

a0c0 |

| 2.20.5. | "Capped inflation" | a3c0 |

| ... | means the process of inflating the tyre to the required cold inflation pressure and allowing the inflation pressure to build up, as the tyre is warmed up while running. | a3c0 |

|

2. |

Parasitic loss | a1c0 |

| ... |

Means the loss of energy (or energy consumed) per unit distance excluding internal tyre losses, attributable to aerodynamic loss of the different rotating elements of the test equipment, bearing friction and other sources of systematic loss which may be inherent in the measurement. |

a6c0 |

|

2. |

Skim test reading | a1c0 |

| ... |

Means a type of parasitic loss measurement, in which the tyre is kept rolling without slippage, while reducing the tyre load to a level at which energy loss within the tyre itself is virtually zero. |

a6c0 |

| 2.20.8. | "Inertia" or "moment of inertia" | a3c0 |

| ... | means the ratio of the torque applied to a rotating body, such as a tyre assembly or machine drum, to the rotational acceleration of this body.[8] | a3c0 |

|

|

|

a0c0 |

| 2.20.9. |

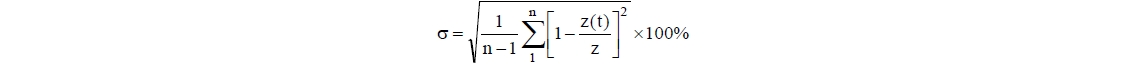

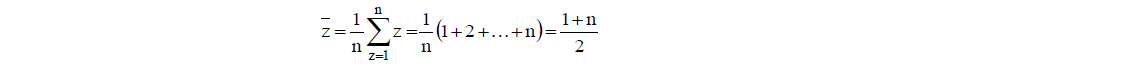

Measurement reproducibility (σm) |

a6c0 |

| ... |

Means the capability of a machine to measure rolling resistance.[9] |

a6c0 |

|

|

|

a0c0 |

| ... |

|

a0c0 |

| ... |

|

a0c0 |

| ... |

|

a0c0 |

| ... |

|

a0c0 |

| 3. |

|

a0c0 |

| 3.1. | The application for approval of a type of tyre with regard to this Regulation shall be submitted by the tyre manufacturer or by his duly accredited representative. It shall specify: | a0c0 |

| 3.1.1. |

The performance characteristics to be assessed for the type of tyre; "rolling sound emissions level" and/or "adhesion performance level on wet surfaces" and/or "rolling resistance level"; "snow performance level" in case of "snow tyre for use in severe snow conditions" and additionally "ice performance level" in case of ice grip tyre;" |

a6c0 |

| 3.1.2. |

Manufacturer's name and address; |

a3c0 |

| 3.1.3. |

If applicable, name and address of [DEL] manufacturer's representative; |

a3c0 |

|

3.1. |

Tyre class (Class C1, C2 or C3) (see paragraph 2.6. of this Regulation); |

a3c0 |

|

3.1. |

Category of use (normal, snow, or special); |

a3c0 |

| 3.1.5.1. |

Whether snow tyre for use in severe snow conditions or not; |

a6c0 |

| 3.1.5.2. |

For classes C2 and C3 tyres, whether traction tyre or not; |

a6c0 |

|

|

For class C1 tyres, whether ice grip tyre or not; |

a6c0 |

|

3.1. |

Tyre structure; |

a3c0 |

|

3.1. |

Brand name(s)/trademark(s), trade description(s)/commercial name(s); |

a3c0 |

|

3.1. |

A list of tyre size designations covered by this application and specifying for each brand name/trademark and/or each trade description/commercial name the applicable tyre size designations and service descriptions, adding in case of Class C1 tyres whether "reinforced" (or "extra load") or not. |

a3c0 |

|

|

[DEL] |

a3c0 |

|

|

[DEL] |

a3c0 |

|

|

[DEL] |

a3c0 |

|

|

[DEL] |

a3c0 |

| ... |

[DEL] |

a3c0 |

| ... |

[DEL] |

a3c0 |

| ... |

[DEL] |

a3c0 |

| ... |

[DEL] |

a3c0 |

| ... |

[DEL] |

a3c0 |

| 3.2. | The application for approval shall be accompanied (in triplicate) by: | a0c0 |

| 3.2.1. |

Details of the major features, with respect to the effects on the performance (i.e. rolling sound emission level, adhesion on wet surfaces, rolling resistance, snow performance and ice performance) of the tyres, including the tread pattern, included in the designated range of tyre sizes. This may be by means of descriptions supplemented by technical data, drawings, photographs or Computer Tomography (CT) scans, and must be sufficient to allow the Type Approval Authority or Technical Service to determine whether any subsequent changes to the major features will adversely affect the tyre performance. The effects of changes to minor details of tyre construction on tyre performances will be evident and determined during checks on conformity of production; |

a6c0 |

| 3.2.2. |

Drawings or photographs of the tyre sidewall, showing the DEL approval marks referred to in paragraph 4., shall be submitted once the production has been established, but no later than one year after the date of granting of type approval; |

a6c0 |

| 3.2.3. | In the case of applications relating to special use tyres, a copy of the mould drawing of the tread pattern shall be supplied in order to allow verification of the void-to-fill ratio. | a0c0 |

| 3.3. | At the request of the Type Approval Authority, the applicant shall submit samples of tyres for test or copies of test reports from the Technical Services, communicated as given in paragraph 11. of this Regulation. | a0c0 |

| 3.4. |

With regard to the application, testing may be confined to a [DEL] representative tyre size of the type of tyre, at the discretion of the Type Approval Authority [DEL]. |

a3c0 |

|

|

|

a1c0 |

| 4. |

|

a0c0 |

| 4.1. | All tyres constituting the type of tyre shall be marked as prescribed by either Regulation No. 30 or 54, as applicable. | a0c0 |

| 4.2. | In particular tyres shall bear:[10] | a0c0 |

| 4.2.1. |

The manufacturer's name or |

a1c0 |

|

|

|

a0c0 |

| 4.2.2. |

The trade description/commercial name (see paragraph 2.4. of this Regulation). However, the trade description is not required when it coincides with the brand name/trademark; |

a6c0 |

| 4.2.3. | The tyre size designation; | a0c0 |

| 4.2.4. | The inscription "REINFORCED" (or alternatively "EXTRA LOAD") if the tyre is classified as reinforced; | a0c0 |

| 4.2.5. | The inscription "TRACTION"[11] if the tyre is classified as "traction tyre"; | a0c0 |

|

|

|

a0c0 |

| 4.2.6. |

The "Alpine Symbol" ("3-peak-mountain with snowflake" conforming to the pictogram described in Annex 7, Appendix 1) DEL if the snow tyre is classified as "snow tyre for use in severe snow conditions"; |

a6c0 |

|

|

The "Ice Grip Symbol" (conforming to the pictogram described in Annex 8, Appendix 1) if the snow tyre for use in severe snow conditions is additionally classified as ice grip tyre; |

a6c0 |

| 4.2.7. | The inscription "MPT" (or alternatively "ML" or "ET") and /or "POR" if the tyre is classified in the category of use "special". | a0c0 |

| ... | ET means Extra Tread, ML stands for Mining and Logging, MPT means Multi-Purpose Truck and POR means Professional Off-Road. | a0c0 |

| 4.3. | Tyres shall provide adequate space for the approval mark as shown in Annex 2 to this Regulation. | a0c0 |

| 4.3.1. |

In case the approval of a tyre pursuant to this Regulation has been granted by the same Type Approval Authority than that granting the approval pursuant to UN Regulations Nos. 30 or 54, the approval mark pursuant to UN Regulations Nos. 30 or 54 can be combined with an indication of the applicable series of amendments to which the tyre was approved pursuant to UN Regulation No. 117 on the form of 2 digits (example "02" indicating that the UN Regulation No.117 approval was granted following the 02 series of amendments) and the suffixes according to paragraph 5.2.2. using the addition sign "+", as described in Annex 2, Appendix 3 of this Regulation, for example "0236378 + 02S1WR2". |

a6c0 |

| 4.4. |

|

a5c0 |

| 4.4.1. |

|

a5c0 |

| 5. |

|

a0c0 |

| 5.1. | If the representative tyre size of the type of tyre submitted for approval pursuant to this Regulation meets the requirements of paragraphs 6. and 7. below, approval of that type of tyre shall be granted. | a0c0 |

| 5.2. |

An approval number |

a2c0 |

|

|

Instead of granting the original type approval number pursuant to UN Regulation No. 117, upon the request of the manufacturer, the Type Approval Authority may grant the type approval number, which had been granted before to that type of tyre pursuant to UN Regulations Nos. 30 or 54 with the subsequent extension number. | a2c0 |

|

|

The communication form mentioned in paragraph 5.3. below shall identify specific performance parameters of UN Regulation No. 117 by the following suffixes: S To identify additional conformity to the requirements on tyre rolling sound emissions; W To identify additional conformity to the requirements on tyre adhesion on wet surfaces; R To identify additional conformity to the requirements on tyre rolling resistance. | a2c0 |

| ... | Taking into account that two stages are defined for rolling sound and rolling resistance specifications in paragraphs 6.1. and 6.3. below, S and R will be followed either by the suffix "1" for compliance to stage 1 or by the suffix "2" for compliance to stage 2. | a2c0 |

| 5.3. | Notice of approval or extension of approval or refusal of approval of a type of tyre pursuant to this Regulation shall be communicated to the Parties to the Agreement, which apply this Regulation by means of a form conforming to the model in Annex 1 to the Regulation. | a0c0 |

| 5.3.1. |

|

a2c0 |

| 5.3.1.1. |

When extension of approval is granted to incorporate into the communication form (see Annex 1 to this Regulation) certification(s) of conformity to other Regulations, (all) the specific type approval number(s) and the Regulation itself shall be added to item 9. of Annex 1 "Communication" DEL. |

a6c0 |

| 5.3.1.2. |

The suffix(es) mentioned in paragraph 5.2.2. above shall be preceded by the two digits identifying the series of amendments of the prescription on tyre performances for UN Regulation No. 117, e.g. "02S2" to identify the second series of amendments on tyre road rolling sound emissions at stage 2 or "02S1WR1" to identify the second series of amendments on tyre road rolling sound emissions at stage 1, tyre adhesion on wet surfaces and rolling resistance at stage 1 (see paragraph 6.1. below for stage 1 and stage 2 definitions). |

a6c0 |

| 5.3.2. | The following suffixes have been already reserved to identify specific Regulations on tyre performance parameters: | a0c0 |

| ... | S To identify additional conformity to the requirements on tyre rolling sound emissions; | a0c0 |

| ... | W To identify additional conformity to the requirements on tyre adhesion on wet surfaces; | a0c0 |

| ... | R To identify additional conformity to the requirements on tyre rolling resistance. | a0c0 |

| ... | Taking into account that two stages are defined for rolling sound and rolling resistance specifications in paragraphs 6.1. and 6.3. below, S and R will be followed either by the suffix "1" for compliance to stage 1 or by the suffix "2" for compliance to stage 2. | a0c0 |

| 5.4. | In the space referred to in paragraph 4.3. and in accordance with the requirements of paragraph 4.4. above there shall be affixed to every tyre size, conforming to the type of tyre approved under this Regulation, an international approval mark consisting of: | a0c0 |

| 5.4.1. | A circle surrounding the letter "E" followed by the distinguishing number of the country which has granted approval;[12] and | a0c0 |

|

|

|

a0c0 |

| 5.4.2. |

The |

a2c0 |

| 5.4.3. | The suffix(es), and the identification to the relevant series of amendments, if any, as specified in the communication form. | a0c0 |

| ... | One of the suffixes listed below or any combination of them can be used. | a0c0 |

| ... |

|

a6c0 |

| ... | These suffixes shall be placed to the right or below the approval number, if part of the original approval. | a0c0 |

| ... |

If the approval is extended subsequent to Regulation Nos. 30 or 54 approvals, the addition sign "+" and the series of amendment to Regulation No. 117 shall be placed in front of the suffix or any combination of suffixes to denote an extension to the approval. |

a6c0 |

| ... |

If the approval is extended subsequent to the original approval under UN Regulation No. 117, the addition sign "+" shall be placed between the suffix or any combination of suffixes of the original approval and the suffix or any combination of suffixes added to denote an extension to the approval. |

a6c0 |

| 5.4.4. |

The marking on the tyre sidewalls of suffix(es) to the approval number removes the requirement for any additional marking on the tyre of the specific type approval number for conformity to the Regulation(s) to which the suffix refers as per paragraph 5.<mod>2</mod>.2. above. |

a5c0 |

| 5.5. | If the tyre conforms to type approvals under one or more other Regulations annexed to the Agreement in the country which has granted approval under this Regulation, the symbol prescribed in paragraph 5.4.1. above need not be repeated. In such a case the additional numbers and symbols of all the Regulations under which approval has been granted in the country which has granted approval under this Regulation shall be placed adjacent to the symbol prescribed in paragraph 5.4.1. above. | a0c0 |

| 5.6. | Annex 2 to this Regulation gives examples of arrangements of approval marks. | a0c0 |

| 6. |

|

a0c0 |

| 6.1. | Rolling sound emission limits, as measured by the method described in Annex 3 to this Regulation. | a0c0 |

| 6.1.1. |

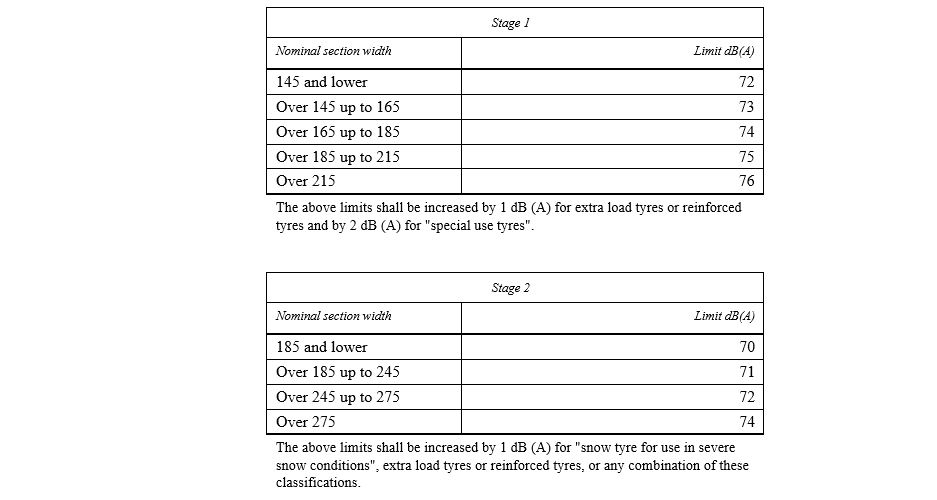

For Class C1 tyres, the rolling sound emission value shall not exceed the values pertinent to the applicable stage given below. These values refer to the nominal section width as DEL defined in UN Regulation No. 30: |

a6c0 |

| ... |

|

a0c0 |

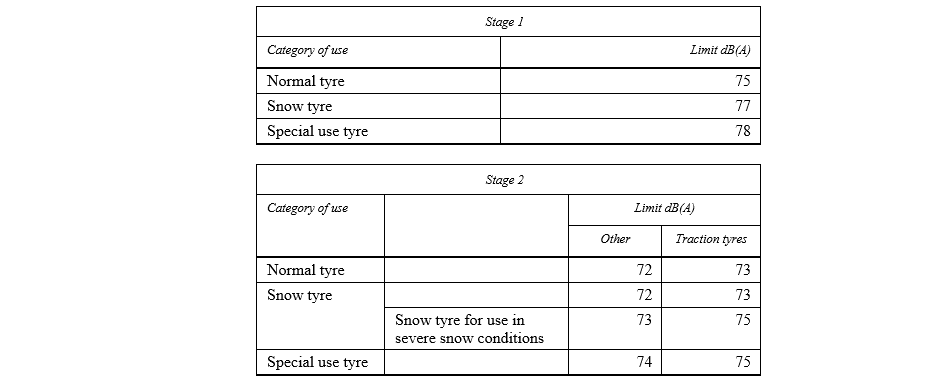

| 6.1.2. |

For class C2 tyres, the rolling sound emission value with reference to its category of use (see paragraph 2.1., subparagraph (d) above) shall not exceed the values pertinent to the applicable stage given below: |

a6c0 |

| ... |

|

a0c0 |

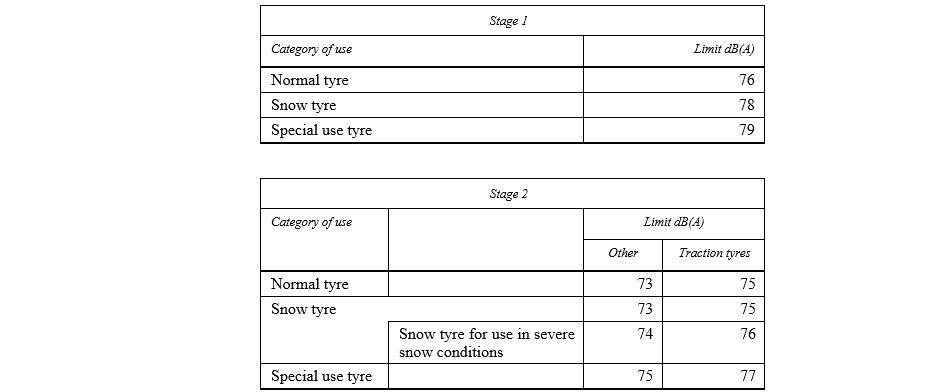

| 6.1.3. |

For class C3 tyres, the rolling sound emission value with reference to its category of use (see paragraph 2.1., subparagraph (d) above) shall not exceed the values pertinent to the applicable stage given below: |

a6c0 |

| ... |

|

a0c0 |

| 6.2. |

The wet DEL adhesion will be based on a procedure that compares either peak brake force coefficient ("pbfc") or mean fully developed deceleration ("mfdd") against values achieved by a Standard Reference Test Tyre (SRTT). The relative performance shall be indicated by a wet grip index (G). |

a6c0 |

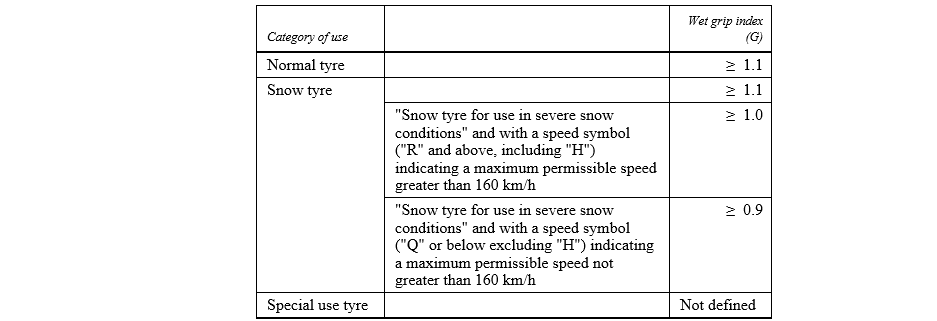

| 6.2.1. |

For class C1 tyres, tested in accordance with either procedure given in Annex 5, Part (A), to this Regulation, the tyre shall meet the following requirements: |

a6c0 |

| ... |

|

a0c0 |

| 6.2.2. |

For class C2 tyres, tested in accordance with either procedure given in Annex 5, Part (B), to this Regulation, the tyre shall meet the following requirements: |

a6c0 |

| ... |

|

a0c0 |

| 6.2.3. |

For class C3 tyres, tested in accordance with either procedure given in Annex 5, Part (B), to this Regulation, the tyre shall meet the following requirements: |

a6c0 |

| ... |

|

a0c0 |

| 6.3. | Rolling resistance coefficient limits, as measured by the method described in Annex 6 to this Regulation. | a0c0 |

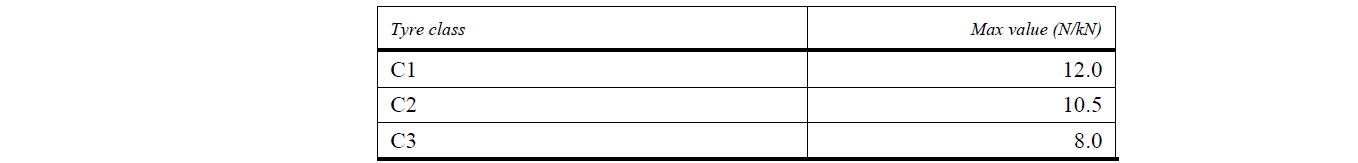

| 6.3.1. | The maximum values for stage 1 for the rolling resistance coefficient shall not exceed the following (value in N/kN is equivalent to value in kg/tonne): | a0c0 |

| ... |

|

a0c0 |

| ... | For "snow tyre for use in severe snow conditions", the limits shall be increased by 1 N/kN. | a0c0 |

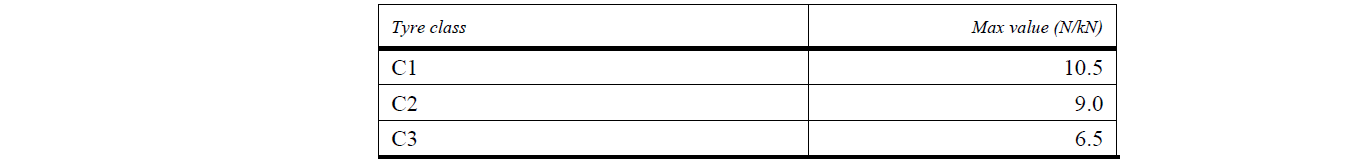

| 6.3.2. | The maximum values for stage 2 for the rolling resistance coefficient shall not exceed the following (value in N/kN is equivalent to value in kg/tonne): | a0c0 |

| ... |

|

a0c0 |

| ... | For "snow tyre for use in severe snow conditions , the limits shall be increased by 1 N/kN. | a0c0 |

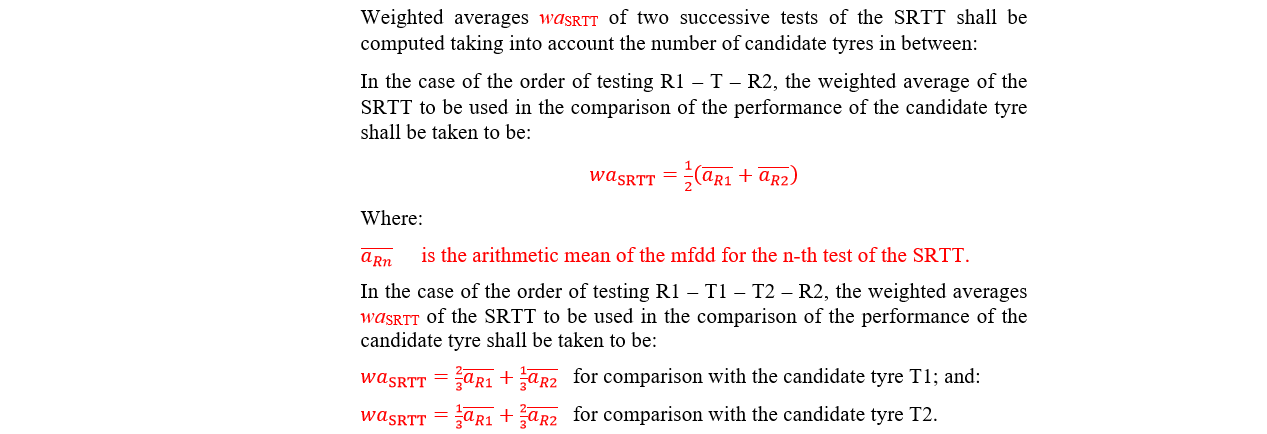

| 6.4. | In order to be classified as a "snow tyre for use in severe snow conditions" the tyre shall meet the performance requirements of paragraph 6.4.1. below. The tyre shall meet these requirements based on a test method of Annex 7 by which: | a0c0 |

| ... | (a) The mean fully developed deceleration ("mfdd") in a braking test, | a0c0 |

| ... | (b) Or alternatively an average traction force in a traction test, | a0c0 |

| ... | (c) Or alternatively the average acceleration in an acceleration test | a0c0 |

| ... |

of the candidate tyre is compared to that of a Standard Reference Test Tyre (SRTT). |

a3c0 |

| ... |

The relative performance shall be indicated by a snow grip index. |

a3c0 |

| 6.4.1. |

DEL Snow performance requirements for classes C1, C2 and C3 tyres |

a6c0 |

|

|

DEL |

a6c0 |

| ... |

The minimum snow grip index value, as calculated in the procedure described in Annex 7 and compared with the respective Standard Reference Test Tyre (SRTT) shall be as follows: |

a3c0 |

| ... |

|

a5c0 |

|

|

Ice performance requirements for class C1 tyres classified as ice grip tyre In order to be classified as ice grip tyre, a snow tyre for use in severe snow conditions shall meet the minimum ice grip index value, as calculated in the procedure described in Annex 8 and compared with the respective Standard Reference Test Tyre (SRTT) shall be as follows:

|

a6c0 |

| 6.5. |

In order to be classified as a "traction tyre", a tyre is required to meet at least one of the conditionDEL of paragraph 6.5.1. below. |

a6c0 |

| 6.5.1. |

The tyre shall have a tread pattern with minimum two circumferential ribs, each containing a minimum of 30 block-like elements, separated by grooves and/or sipe elements the depth of which has to be minimum of one half of the tread depth. The use of an alternative option of a physical test will only apply at a later stage following a further amendment to the Regulation including a reference to DEL appropriate test methods and limit values. |

a6c0 |

| 6.6. | In order to be classified as a "special use tyre" a tyre shall have a block tread pattern in which the blocks are larger and more widely spaced than for normal tyres and have the following characteristics: | a0c0 |

| ... |

For class C1 tyres: a tread depth ≥ 11 mm and void to fill ratio ≥ 35 per cent |

a6c0 |

| ... |

For class C2 tyres: a tread depth ≥ 11 mm and void to fill ratio ≥ 35 per cent |

a6c0 |

| ... |

For class C3 tyres: a tread depth ≥ 16 mm and void to fill ratio ≥ 35 per cent |

a6c0 |

| 6.7. | In order to be classified as a "professional off-road tyre", a tyre shall have all of the following characteristics: | a0c0 |

| ... |

(a) For classes C1 and C2 tyres: |

a6c0 |

| ... | (i) A tread depth ≥ 11 mm; | a0c0 |

| ... | (ii) A void-to-fill ratio ≥ 35 per cent; | a0c0 |

| ... | (iii) A maximum speed rating of ≤ Q. | a0c0 |

| ... |

(b) For class C3 tyres: |

a6c0 |

| ... | (i) A tread depth ≥ 16 mm; | a0c0 |

| ... | (ii) A void-to-fill ratio ≥ 35 per cent; | a0c0 |

| ... | (iii) A maximum speed rating of Ͱa K. | a0c0 |

| 7. |

|

a1c0 |

| 7.1. | Every modification of the type of tyre, which may influence the performance characteristics approved in accordance with this Regulation, shall be notified to the Type Approval Authority which approved the type of tyre. That Authority may either: | a0c0 |

| 7.1.1. | Consider that the modifications are unlikely to have any appreciable adverse effect on the performance characteristics approved and that the tyre will comply with the requirements of this Regulation; or | a0c0 |

| 7.1.2. | Require further samples to be submitted for test or further test reports from the designated Technical Service. | a0c0 |

|

7. |

Confirmation or refusal of approval, specifying the modifications, shall be communicated by the procedure given in paragraph 5.3. of this Regulation to the Parties to the Agreement which apply this Regulation. |

a5c0 |

|

7. |

The Type Approval Authority granting the extension of approval shall assign a series number for such an extension which shall be shown on the communication form. |

a5c0 |

| 8. |

|

a0c0 |

| ... |

The conformity of production procedures shall comply with those set out in the 1958 Agreement, Schedule 1 (E/ECE/324-E/ECE/TRANS/505/Rev.3) with the following requirements: |

a6c0 |

| 8.1. | Any tyre approved under this Regulation shall be so manufactured as to conform to the performance characteristics of the type of tyre approved and satisfy the requirements of paragraph 6. above; | a0c0 |

| 8.2. |

DEL The authority which has granted type approval may at any time verify the conformity control methods applied by the manufacturer. In general, the conformity control methods should take into consideration the production volumes of the type of tyre at each manufacturing facility. The normal frequency of these verifications shall be at least once every two years. |

a6c0 |

|

|

Verification tests shall be carried out on random samples of tyres bearing the approval mark required by this Regulation taken from the series production. Where the test procedure involves testing a number of tyres at the same time, for example a set of four tyres for the purpose of measuring wet adhesion in accordance with the standard vehicle procedure given in Annex 5 to this Regulation, then the set shall be considered as being one unit for the purposes of calculating the number of tyres to be tested. The Type Approval Authority shall satisfy itself that all tyres falling within an approved type comply with the approval requirement. |

a6c0 |

|

8. |

In the case of verification tests with regard to approvals in accordance with paragraph 6.2. of this Regulation, these shall be carried out using the same testing method (see Annex 5 to this Regulation) as that adopted for original approval. |

a6c0 |

|

|

In the case of verification tests with regard to approvals in accordance with paragraph 6.4. of this Regulation, these shall be carried out using the same testing method (see Annex 7 to this Regulation) as that adopted for original approval. |

a6c0 |

|

8. |

Production shall be deemed to conform to the requirements of this Regulation if the levels measured comply with the limits prescribed in paragraph 6.1. of this Regulation, with an additional allowance of +1 dB(A) for possible mass production variations. |

a6c0 |

|

8. |

Production shall be deemed to conform to the requirements of this Regulation if the levels measured comply with the limits prescribed in paragraph 6.3. of this Regulation, with an additional allowance of +0.3 N/kN for possible mass production variations. |

a6c0 |

| 9. |

|

a0c0 |

| 9.1. |

The approval granted in respect of a type of tyre pursuant to this Regulation may be withdrawn if the requirements laid down in paragraph 8. above are not complied with, or if any tyre of the type of tyre exceeds the limits given in paragraphs 8. |

a5c0 |

| 9.2. | If a Party to the Agreement, which applies this Regulation, withdraws an approval, it has previously granted, it shall forthwith notify the other Contracting Parties applying this Regulation by means of a copy of the approval form conforming to the model in Annex 1 to this Regulation. | a0c0 |

| 10. |

|

a0c0 |

| ... |

If the holder of an approval completely ceases to manufacture a type of |

a1c0 |

| 11. |

|

a0c0 |

|

|

The |

a1c0 |

|

|

|

a1c0 |

|

|

|

a1c0 |

| 12. |

|

a0c0 |

| 12.1. |

As from the date of entry into force of the 02 series of amendments to this Regulation, Contracting Parties applying this Regulation shall not refuse to grant approval under this Regulation for a type of tyre if the tyre complies with the requirements of the 02 series of amendments, including the stage 1 or stage 2 rolling sound requirements set out in paragraphs 6.1.1. to 6.1.3. of this Regulation, the requirements for wet adhesion set out in paragraph 6.2.1. of this Regulation, and the stage 1 or stage 2 rolling resistance requirements set out in paragraph 6.3.1. or 6.3.2. of this Regulation. |

a6c0 |

| 12.2. |

As from 1 November 2012, Contracting Parties applying this Regulation shall refuse to grant approval if the type of tyre to be approved does not meet the requirements of this Regulation as amended by the 02 series of amendments, and shall, in addition, refuse to grant approval if the stage 2 rolling sound requirements set out in paragraphs 6.1.1. to 6.1.3. of this Regulation, the requirements for wet adhesion set out in paragraph 6.2.1. of this Regulation, and the stage 1 rolling resistance requirements set out in paragraph 6.3.1. of this Regulation are not complied with. |

a6c0 |

| 12.3. |

As from 1 November 2014, Contracting Parties applying this Regulation may refuse to allow the sale or entry into service of a tyre which does not meet the requirements of this Regulation as amended by the 02 series, and which does not meet the requirements of this Regulation as amended by the 02 series of amendments including the wet adhesion requirements set out in paragraph 6.2.1. of this Regulation. |

a6c0 |

| 12.4. |

As from 1 November 2016, Contracting Parties applying this Regulation shall refuse to grant approvals if the type of tyre to be approved does not meet the requirements of this Regulation as amended by the 02 series of amendments including the stage 2 rolling resistance requirements set out in paragraph 6.3.2. of this Regulation and the wet adhesion requirements set out in paragraphs 6.2.2. and 6.2.3. of this Regulation. |

a6c0 |

| 12.5. | As from 1 November 2016, any Contracting Party applying this Regulation may refuse to allow the sale or entry into service of a tyre which does not meet the requirements of this Regulation as amended by the 02 series, and which does not meet the stage 2 rolling sound requirements set out in paragraphs 6.1.1. to 6.1.3. of this Regulation. | a0c0 |

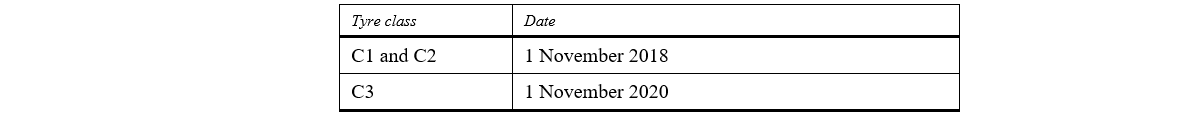

| 12.6. | As from the dates given below, any Contracting Party applying this Regulation may refuse to allow the sale or entry into service of a tyre which does not meet the requirements of this Regulation as amended by the 02 series, and which does not meet the stage 1 rolling resistance requirements set out in paragraph 6.3.1. of this Regulation: | a0c0 |

| ... |

|

a0c0 |

| 12.7. |

As from the dates given below, any Contracting Party applying this Regulation may refuse to allow the sale or entry into service of a tyre which does not meet the requirements of this Regulation as amended by the 02 series, and which does not meet the stage 2 rolling resistance requirements set out in paragraph 6.3.2. of this Regulation and the wet adhesion requirements set out in paragraphs 6.2.2. and 6.2.3. of this Regulation: |

a6c0 |

| ... |

|

a0c0 |

| 12.8. | Until 13 February 2019 (60 months after the entry into force of Supplement 4 to the 02 series of amendments to this Regulation) Contracting Parties applying this Regulation may continue to grant type approvals according to the 02 series of amendments to this Regulation, based on the provisions of Annex 4 to this Regulation. | a0c0 |

|

|

Until 3 months after the date of entry into force of Supplement 11 to the 02 series of amendments to this Regulation, Contracting Parties applying this Regulation can continue to grant type approvals according to the 02 series of amendments to this Regulation, without taking into account the provisions of Supplement 11. |

a3c0 |

|

|

|

a5c0 |

|

|

|

a5c0 |

| ... |

|

a5c0 |

| 12.12. |

Until 1 September 2024, Contracting Parties applying this Regulation may continue to grant type approvals according to the 02 series of amendments to this Regulation, based on the test procedures for measuring wet adhesion described in Annex 5 of this Regulation, without taking into account the provisions of Supplement 13. |

a6c0 |

|

|

Until 3 months after the date of entry into force of Supplement 14 to the 02 series of amendments to this Regulation, Contracting Parties applying this Regulation can continue to grant type approvals according to the 02 series of amendments to this Regulation, without taking into account the provisions of Supplement 14. |

a6c0 |

| A1 |

|

a0c0 |

| A1 |

|

a0c0 |

| A1 | (maximum format: A4 (210 x 297 mm)) | a0c0 |

| A1 |

|

a0c0 |

| A1 | of a type of tyre with regard to "rolling sound emission level" and/or "adhesion performance on wet surfaces" and/or "rolling resistance" pursuant to Regulation No. 117 | a0c0 |

|

A1 |

|

a0c0 |

|

A1 |

|

a0c0 |

| A1 | a0c0 | |

| A1 |

Approval No. |

a2c0 |

| A1 1. |

Manufacturer's name and address [DEL]: |

a1c0 |

| A1 2. | If applicable, name and address of manufacturer's representative: | a0c0 |

| A1 3. |

"Tyre class" [DEL] of the type of tyre: |

a0c0 |

|

A1 |

Category of use" of the type of tyre: |

a3c0 |

|

A1 |

Snow tyre for use in severe snow conditions (Yes/No)[2] |

a3c0 |

|

A1 |

Ice grip tyre (Yes/No)[2] |

a6c0 |

|

A1 |

Traction tyre (Yes/No)[2] |

a3c0 |

|

A1 |

|

a2c0 |

|

A1 |

|

a2c0 |

|

A1 |

Tyre structure: |

a3c0 |

| A1 6. |

Type of tyre designation: |

a6c0 |

|

A1 |

Brand name(s)/trademark(s) of the type of tyre: |

a3c0 |

| A1 6.2. |

Trade description(s)/ commercial name(s) of the type of tyre: |

a6c0 |

|

A1 |

Technical service and, where applicable, test laboratory approved for purposes of approval or of verification of conformity tests: |

a3c0 |

|

A1 |

Performance(s) approved: sound level at (stage 1/stage 2),[2] wet adhesion level, rolling resistance level (stage 1/stage 2)[2] |

a3c0 |

|

A1 |

Sound level of the representative tyre size, see paragraph 2.7. of this Regulation, as per item 7. of the test report in Appendix 1 to Annex 3: ................ dB(A) at reference speed of 70/80 km/h [2] |

a3c0 |

| A1 8.2. |

Wet adhesion level of the representative tyre size, see paragraph 2.7. of this Regulation, as per DEL the test report examples shown in the appendix to Annex 5: ……………………… (G) using the vehicle or trailer method [2] |

a6c0 |

|

A1 |

Rolling resistance level of the representative tyre size, see paragraph 2.7. of this Regulation, as per item 7. of the test report in Appendix 1 to Annex 6 |

a3c0 |

| A1 8.4. |

Snow performance level of the representative tyre size, see paragraph 2.7. of DEL Regulation No. 117, as per item 7. of the test report in the appendix [5] to Annex 7:………………. (snow grip index) using the brake on snow method [2], spin traction method [2] or acceleration method [2]. |

a6c0 |

|

A1 |

Ice performance level of the representative tyre size, see paragraph 2.7. of Regulation No. 117, as per item 7. of the test report in the appendix 2 to Annex 8:…………………….…(ice grip index) using the brake on ice method. [2] |

a6c0 |

|

A1 |

Number of report issued by the Technical Service: |

a3c0 |

|

A1 |

Date of report issued by that Service: |

a3c0 |

|

A1 |

Reason(s) of extension (if applicable): |

a3c0 |

|

A1 |

Any remarks: |

a3c0 |

|

A1 |

Place: |

a3c0 |

|

A1 |

Date: |

a3c0 |

|

A1 |

Signature: |

a3c0 |

|

A1 |

Annexed to this communication are: |

a3c0 |

| A1 16.1. |

A list of documents in the approval file deposited at the Type Approval Authorities having delivered the approval and which can be obtained upon request. |

a5c0 |

| A1 16.2. |

A list of tyre size designations: Specify for each brand name/trademark and/or each trade description/commercial name the list of tyre size designations and service descriptions, adding in case of class C1 tyres whether "reinforced" (or "extra load") or not. |

a6c0 |

|

A1 |

|

a6c0 |

| A1 |

|

a6c0 |

|

A1 |

|

a5c0 |

| A2 |

|

a0c0 |

| A2 |

|

a6c0 |

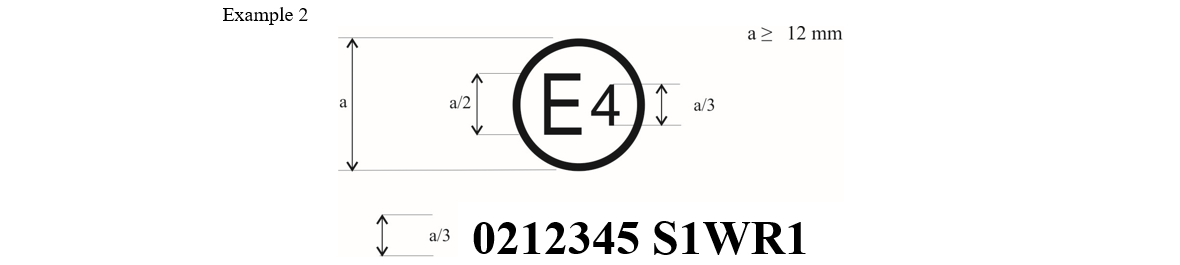

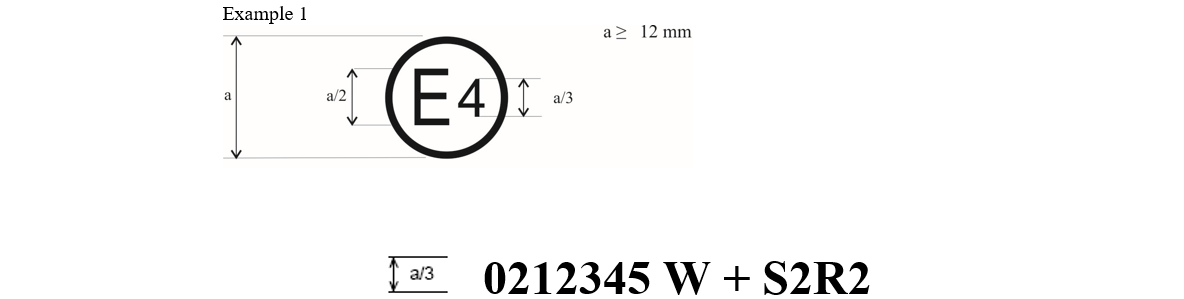

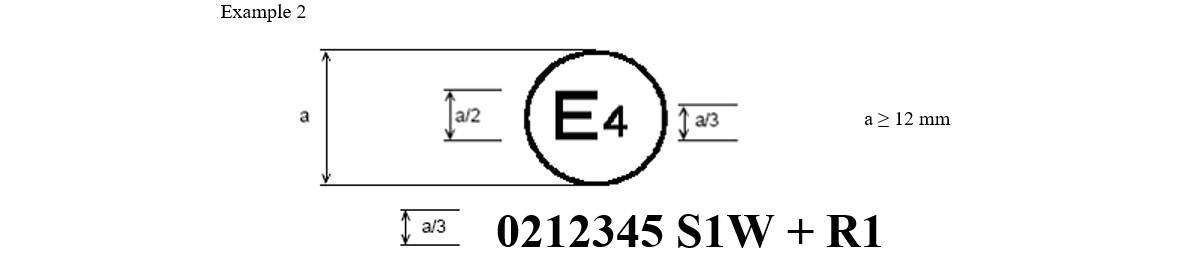

| A2 | Arrangements of approval marks | a0c0 |

| A2 | (See paragraph 5.4. of this Regulation) | a0c0 |

| A2 | Approval according to Regulation No. 117 | a0c0 |

| A2 |

|

a0c0 |

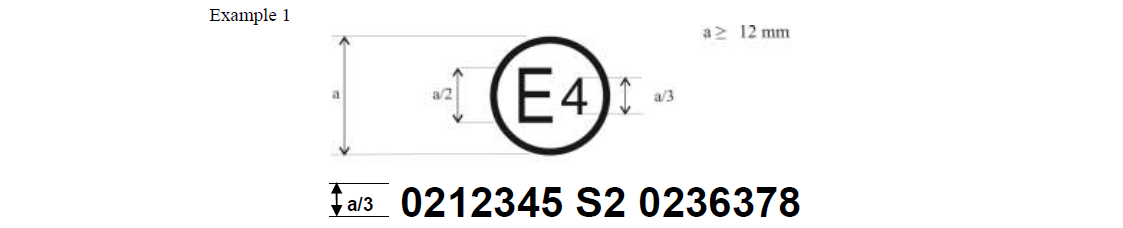

| A2 |

The above approval mark, affixed to a tyre shows that a tyre concerned has been approved in the Netherlands (E 4) pursuant to Regulation No. 117 (marked by "S2") DEL, under approval number 0212345. This indicates that the approval is for rolling sound at stage 2 (S2). The first two digits of the approval number (02) indicate that the approval was granted in accordance with this Regulation which included 02 series of amendments DEL. |

a6c0 |

| A2 |

|

a0c0 |

| A2 |

The above approval mark shows that the tyre concerned has been approved in the Netherlands (E 4) pursuant to Regulation No. 117 (marked by "S1WR1") under approval number 0212345. This indicates that the approval is for rolling sound at stage 1 (S1), wet adhesion (W) and rolling resistance at stage 1 (R1). The first two digits of the approval number ("02") indicate that the approval was granted in accordance with this Regulation which included the 02 series of amendments. |

a6c0 |

| A2 |

|

a0c0 |

| A2 |

|

a6c0 |

|

A2 |

|

a0c0 |

| A2 |

|

a0c0 |

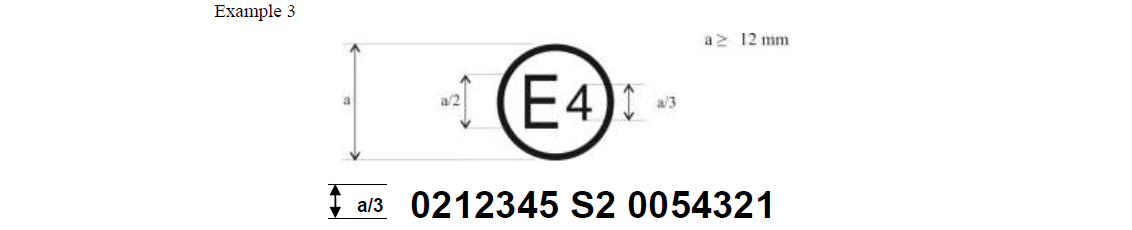

| A2 |

The above approval mark shows that the tyre concerned has been approved in the Netherlands (E 4) pursuant to UN Regulation No. 117 (marked by "S2" DEL), under approval number 0212345 and UN Regulation No. 30, under approval number 0236378. This indicates that the approval is for rolling sound at stage 2 (S2). The first two digits of the approval number ("02") in conjunction with "S2" indicate that the approval was granted in accordance with UN Regulation No. 117 which included the 02 series of amendments. The first two digits of the UN Regulation No. 30 approval number ("02") indicate that this Regulation included the 02 series of amendments. |

a6c0 |

| A2 |

|

a6c0 |

| A2 |

The above approval mark shows that the tyre concerned has been approved in the Netherlands (E 4) pursuant to UN Regulation No. 117 (marked by S2WR2 DEL ), under approval number 0212345 and Regulation No. 30 under approval number 0236378. The first two digits of the approval number (02) indicate that the approval was granted according to the 02 series of amendments and Regulation No. 30 included the 02 series of amendments. The above approval mark shows that the tyre concerned has been approved in the Netherlands (E 4) pursuant to UN Regulation No. 117 (marked by "S2WR2" DEL), under approval number 0212345 and UN Regulation No. 30, under approval number 0236378. This indicates that the approval is for rolling sound at stage 2 (S2), wet adhesion (W) and rolling resistance at stage 2 (R2). The first two digits of the approval number ("02") in conjunction with "S2WR2" indicate that the first approval was granted in accordance with UN Regulation No. 117 which included the 02 series of amendments. The first two digits of the UN Regulation No. 30 approval number ("02") indicate that this Regulation included the 02 series of amendments. |

a6c0 |

| A2 |

|

a0c0 |

| A2 | The above approval mark shows that the tyre concerned has been approved in the Netherlands (E 4) pursuant to Regulation No. 117 and the 02 series of amendments under approval number 0212345 (marked by S2), and Regulation No. 54. This indicates that the approval is for rolling sound stage 2 (S2). The first two digits of the Regulation No. 117 approval number (02) in conjunction with "S2" indicate that the first approval was granted in accordance with Regulation No. 117 which included the 02 series of amendments. The first two digits of Regulation No. 54 (00) indicate that this Regulation was in its original form. | a0c0 |

| A2 |

|

a0c0 |

| A2 | The above approval mark shows that the tyre concerned has been approved in the Netherlands (E 4) pursuant to Regulation No. 117 and the 02 series of amendments under approval number 0212345 (marked by S2 R2), and Regulation No. 54. This indicates that the approval is for rolling sound stage 2 (S2) and rolling resistance stage 2. The first two digits of the Regulation No. 117 approval number (02) in conjunction with "S2R2" indicate that the first approval was granted in accordance with Regulation No. 117 which included the 02 series of amendments. The first two digits of Regulation No. 54 (00) indicate that this Regulation was in its original form. | a0c0 |

| A2 |

|

a0c0 |

| A2 |

|

a5c0 |

|

A2 |

|

a0c0 |

| A2 |

|

a0c0 |

| A2 |

The above approval mark shows that the tyre concerned has been |

a5c0 |

| A2 |

|

a0c0 |

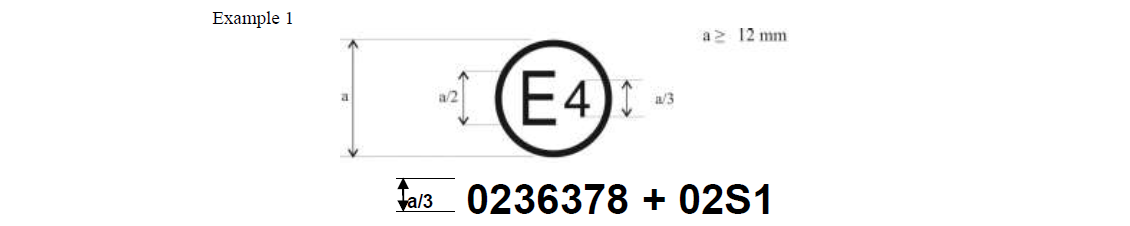

| A2 |

The above approval mark shows that the tyre concerned has been approved in the Netherlands (E 4) pursuant to Regulation No. 30 according to its 02 series of amendments (indicated by the first two digits of the approval number, "02") under approval number 0236378. It is also marked by "+ 02S1WR2" which indicates that the tyre was also approved pursuant to UN Regulation No. 117 (02 series of amendments) for S1 (rolling sound at stage 1), W (wet adhesion) and R2 (rolling resistance at stage 2) |

a6c0 |

| A2 |

|

a0c0 |

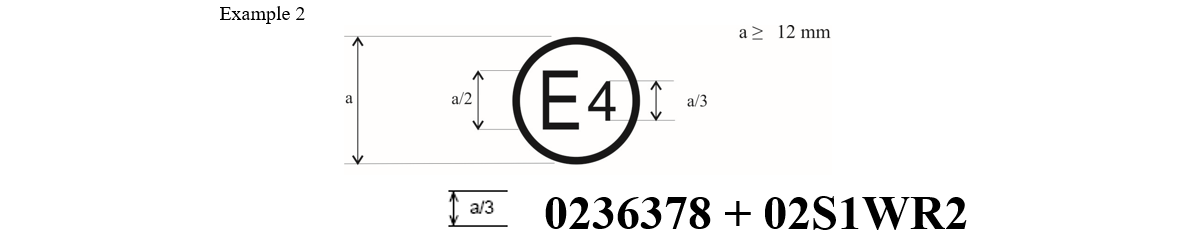

| A2 |

|

a6c0 |

|

A2 |

|

a6c0 |

| A2 |

|

a0c0 |

| A2 |

The above approval mark shows that the tyre concerned has been initially approved in the Netherlands (E 4) pursuant to UN Regulation No. 117 according to its 02 series of amendments (indicated by the first two digits of the approval number, "02") under approval number 0212345 (marked by "W"). This indicates that the approval is for W (wet adhesion). The "S2R2" preceded by "+" indicates that its approval has been extended under UN Regulation No. 117 to rolling sound at stage 2 and rolling resistance at stage 2 based on separate certificate(s). |

a6c0 |

| A2 |

|

a0c0 |

| A2 |

The above approval mark shows that the tyre concerned has been initially approved in the Netherlands (E 4) pursuant to UN Regulation No. 117 according to its 02 series of amendments (indicated by the first two digits of the approval number, "02") under approval number 0212345 (marked by "S1W"). This indicates that the approval is for S1 (rolling sound at stage 1) and W (wet adhesion). The "R1" preceded by "+" indicates that its approval has been extended under Regulation No. 117 to rolling resistance at stage 1 based on separate certificate(s). |

a6c0 |

| A2 |

|

a0c0 |

| A2 |

The above approval mark shows that the tyre concerned has been initially approved in the Netherlands (E 4) pursuant to UN Regulation No. 117 according to its 01 series of amendments (indicated by the first two digits of the approval number, "01") under approval number 0167890 (marked by "SW"). This indicates that the approval is for S (rolling sound at stage 1) and W (wet adhesion). The "02R1" preceded by "+" indicates that its approval has been extended under UN Regulation No. 117 according to its 02 series of amendments to rolling resistance at stage 1 based on separate certificate(s). |

a6c0 |

| A3 |

|

a0c0 |

| A3 |

|

a0c0 |

| A3 | Introduction | a0c0 |

| A3 | The presented method contains specifications on measuring instruments, measurement conditions and the measurement method, in order to obtain the sound level of a set of tyres mounted on a test vehicle rolling on a specified road surface. The maximum sound pressure level is to be recorded, when the test vehicle is coasting, by remote-field microphones; the final result for a reference speed is obtained from a linear regression analysis. Such test results cannot be related to tyre rolling sound measured during acceleration under power or deceleration under braking. | a0c0 |

| A3 1. | Measuring instruments | a0c0 |

| A3 1.1. | Acoustic measurements | a0c0 |

| A3 |

The sound level meter or the equivalent measuring system, including the windscreen recommended by the manufacturer shall meet or exceed the requirements of Type 1 instruments in accordance with [DEL] IEC 61672-1:2013. |

a3c0 |

| A3 | The measurements shall be made using the frequency weighting A, and the time weighting F. | a0c0 |

| A3 | When using a system that includes a periodic monitoring of the A-weighted sound level, a reading should be made at a time interval not greater than 30 ms. | a0c0 |

| A3 1.1.1. | Calibration | a0c0 |

| A3 |

At the beginning and at the end of every measurement session, the entire measurement system shall be checked by means of a sound calibrator that fulfils the requirements for sound calibrators of at least precision Class 1 according to IEC 60942:[DEL]2017. Without any further adjustment the difference between the readings of two consecutive checks shall be less than or equal to 0.5 dB(A). If this value is exceeded, the results of the measurements obtained after the previous satisfactory check shall be discarded. |

a3c0 |

| A3 1.1.2. | Compliance with requirements | a0c0 |

| A3 | The compliance of the sound calibration device with the requirements of IEC 60942:1988 shall be verified once a year and the compliance of the instrumentation system with the requirements of IEC 60651:1979/A1:1993, second edition shall be verified at least every two years, by a laboratory which is authorized to perform calibrations traceable to the appropriate standards. | a0c0 |

| A3 1.1.3. | Positioning of the microphone | a0c0 |

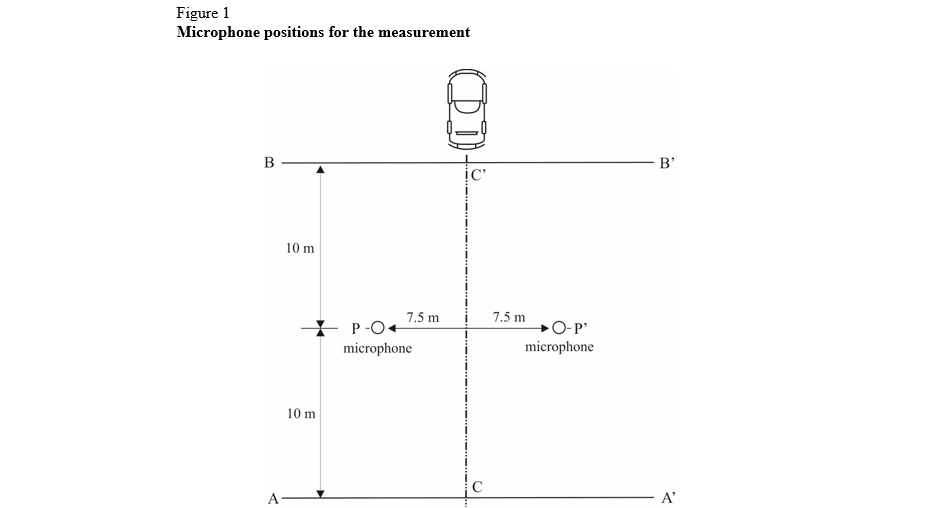

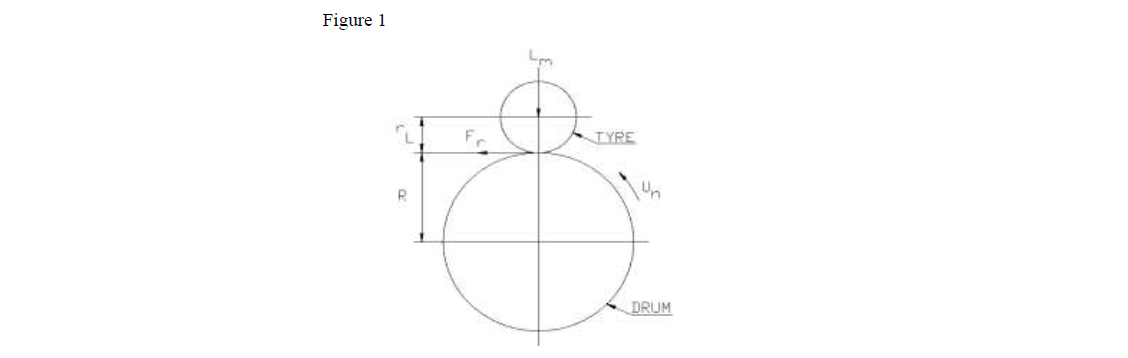

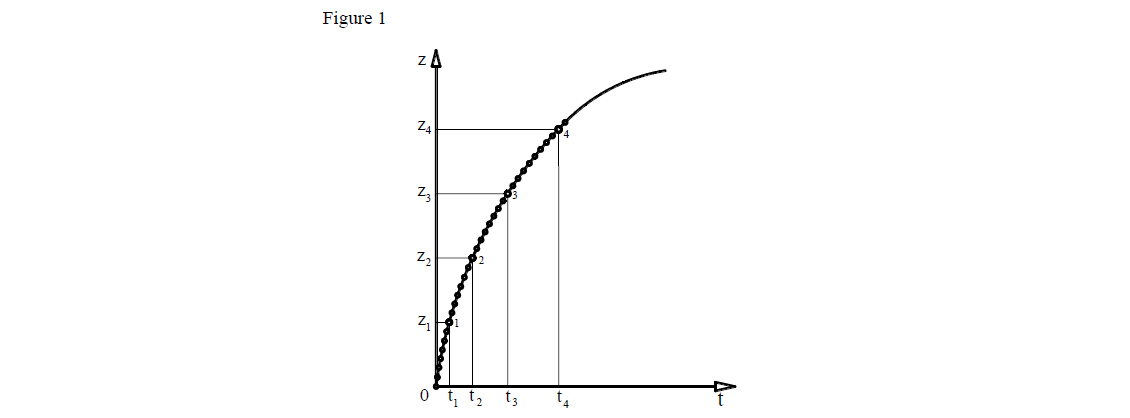

| A3 | The microphone (or microphones) shall be located at a distance of 7.5 ± 0.05 m from track reference line CC' (Figure 1) and 1.2 ± 0.02 m above the ground. Its axis of maximum sensitivity shall be horizontal and perpendicular to the path of the vehicle (line CC'). | a0c0 |

| A3 1.2. | Speed measurements | a0c0 |

| A3 | The vehicle speed shall be measured with instruments with accuracy of ± 1 km/h or better when the front end of the vehicle has reached line PP (Figure 1). | a0c0 |

| A3 1.3. | Temperature measurements | a0c0 |

| A3 | Measurements of air as well as test surface temperature are mandatory. | a0c0 |

| A3 | The temperature measuring devices shall be accurate within ± 1 °C. | a0c0 |

| A3 1.3.1. | Air temperature | a0c0 |

| A3 | The temperature sensor is to be positioned in an unobstructed location close to the microphone in such a way that it is exposed to the airflow and protected from direct solar radiation. The latter may be achieved by any shading screen or similar device. The sensor should be positioned at a height of 1.2 ± 0.1 m above the test surface level, to minimize the influence of the test surface thermal radiation at low airflows. | a0c0 |

| A3 1.3.2. | Test surface temperature | a0c0 |

| A3 | The temperature sensor is to be positioned in a location where the temperature measured is representative of the temperature in the wheel tracks, without interfering with the sound measurement. | a0c0 |

| A3 | If an instrument with a contact temperature sensor is used, heat-conductive paste shall be applied between the surface and the sensor to ensure adequate thermal contact. | a0c0 |

| A3 | If a radiation thermometer (pyrometer) is used, the height should be chosen to ensure that a measuring spot with a diameter of ≥ 0.1 m is covered. | a0c0 |

| A3 1.4. | Wind measurement | a0c0 |

| A3 | The device shall be capable of measuring the wind speed with a tolerance of ± 1 m/s. The wind shall be measured at microphone height. The wind direction with reference to the driving direction shall be recorded. | a0c0 |

| A3 2. | Conditions of measurement | a0c0 |

| A3 2.1. | Test site | a0c0 |

| A3 | The test site shall consist of a central section surrounded by a substantially flat test area. The measuring section shall be level; the test surface shall be dry and clean for all measurements. The test surface shall not be artificially cooled during or prior the testing. | a0c0 |

| A3 | The test track shall be such that the conditions of a free sound field between the sound source and the microphone are attained to within 1 dB(A). These conditions shall be deemed to be met if there is no large sound reflecting objects, such as fences, rocks, bridges or building within 50 m of the centre of the measuring section. The surface of the test track and the dimensions of the test site shall be in accordance with ISO 10844:2014. Until the end of the period indicated in paragraph 12.8. of this Regulation the specifications for the test site may be in accordance with Annex 4 to this Regulation. | a0c0 |

| A3 | A central part of at least 10 m radius shall be free of powdery snow, tall grass, loose soil, cinders or the like. There shall be no obstacle, which could affect the sound field within the vicinity of the microphone and no persons shall stand between the microphone and the sound source. The operator carrying out the measurements and any observers attending the measurements shall position themselves so as not to affect the readings of the measuring instruments. | a0c0 |

| A3 2.2. | Meteorological conditions | a0c0 |

| A3 | Measurements shall not be made under poor atmospheric conditions. It shall be ensured that the results are not affected by gusts of wind. Testing shall not be performed if the wind speed at the microphone height exceeds 5 m/s. | a0c0 |

| A3 | Measurements shall not be made if the air temperature is below 5 °C or above 40 °C or the test surface temperature is below 5 °C or above 50 °C. | a0c0 |

| A3 2.3. | Ambient noise | a0c0 |

| A3 2.3.1. | The background sound level (including any wind noise) shall be at least 10 dB(A) less than the measured tyre rolling sound emission. A suitable windscreen may be fitted to the microphone provided that account is taken of its effect on the sensitivity and directional characteristics of the microphone. | a0c0 |

| A3 2.3.2. | Any measurement affected by a sound peak which appears to be unrelated to the characteristics of the general sound level of tyres, shall be ignored. | a0c0 |

| A3 2.4. | Test vehicle requirements | a0c0 |

| A3 2.4.1. | General | a0c0 |

| A3 | The test vehicle shall be a motor vehicle and be fitted with four single tyres on just two axles. | a0c0 |

| A3 2.4.2. | Vehicle load | a0c0 |

| A3 | The vehicle shall be loaded such as to comply with the test tyre loads as specified in paragraph 2.5.2. below. | a0c0 |

| A3 2.4.3. | Wheelbase | a0c0 |

| A3 |

The wheelbase between the two axles fitted with the test tyres shall for class C1 be less than 3.50 m and for class C2 and class C3 tyres be less than 5 m. |

a6c0 |

| A3 2.4.4. | Measures to minimize vehicle influence on sound level measurements | a0c0 |

| A3 | To ensure that tyre rolling sound is not significantly affected by the test vehicle design the following requirements and recommendations are given. | a0c0 |

| A3 2.4.4.1. | Requirements: | a0c0 |

| A3 | (a) Spray suppression flaps or other extra device to suppress spray shall not be fitted; | a0c0 |

| A3 | (b) Addition or retention of elements in the immediate vicinity of the rims and tyres, which may screen the emitted sound, is not permitted; | a0c0 |

| A3 | (c) Wheel alignment (toe in, camber and caster) shall be in full accordance with the vehicle manufacturer's recommendations; | a0c0 |

| A3 | (d) Additional sound absorbing material may not be mounted in the wheel housings or under the underbody; | a0c0 |

| A3 | (e) Suspension shall be in such a condition that it does not result in an abnormal reduction in ground clearance when the vehicle is loaded in accordance with the testing requirement. If available, body level Regulation systems shall be adjusted to give a ground clearance during testing which is normal for unladen condition. | a0c0 |

| A3 2.4.4.2. | Recommendations to avoid parasitic noise: | a0c0 |

| A3 | (a) Removal or modification on the vehicle that may contribute to the background noise of the vehicle is recommended. Any removals or modifications shall be recorded in the test report; | a0c0 |

| A3 | (b) During testing it should be ascertained that brakes are not poorly released, causing brake noise; | a0c0 |

| A3 | (c) It should be ascertained that electric cooling fans are not operating; | a0c0 |

| A3 | (d) Windows and sliding roof of the vehicle shall be closed during testing. | a0c0 |

| A3 2.5. | Tyres | a0c0 |

| A3 2.5.1. | General | a0c0 |

| A3 |

Four identical tyres shall be fitted on the test vehicle. In the case of class C3 tyres with a load capacity index in excess of 121 and without any dual fitting indication, two of these tyres of the same type and range shall be fitted to the rear axle of the test vehicle; the front axle shall be fitted with tyres of size suitable for the axle load and planed down to the minimum depth in order to minimize the influence of tyre/road contact noise while maintaining a sufficient level of safety. In the case of class C2 tyres with a load capacity index lower or equal to 121, with a section width wider than 200 mm, an aspect ratio lower than 55, a rim diameter code lower than 15 and without any dual fitting indication, two of these tyres of the same type and range shall be fitted to the rear axle of the test vehicle; the front axle shall be fitted with tyres of a size suitable for the axle load and planed down to the minimum depth in order to minimize the influence of tyre/road contact noise while maintaining a sufficient level of safety. Tyres with special fitting requirements shall be tested in accordance with these requirements (e.g. rotation direction). The tyres shall have full tread depth before being run-in. Tyres are to be tested on rims permitted by the tyre manufacturer." |

a6c0 |

| A3 | Tyres are to be tested on rims permitted by the tyre manufacturer. | a0c0 |

| A3 2.5.2. | Tyre loads | a0c0 |

| A3 | The test load Qt for each tyre on the test vehicle shall be 50 to 90 per cent of the reference load Qr, but the average test load Qt,avr of all tyres shall be 75 ± 5 per cent of the reference load Qr. | a0c0 |

| A3 | For all tyres the reference load Qr corresponds to the maximum mass associated with the load capacity index of the tyre. In the case where the load capacity index is constituted by two numbers divided by slash (/), reference shall be made to the first number. | a0c0 |

| A3 2.5.3. | Tyre inflation pressure | a0c0 |

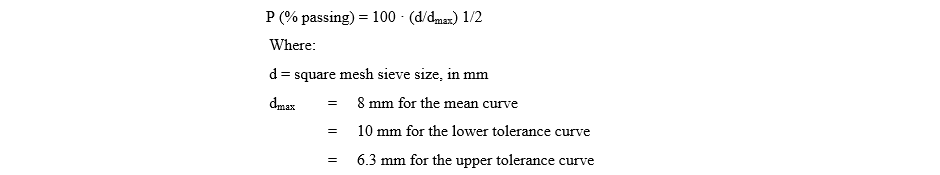

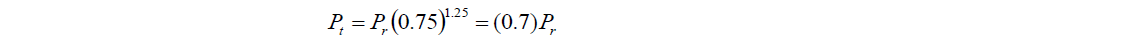

| A3 | Each tyre fitted on the test vehicle shall have a test pressure Pt not higher than the reference pressure Pr and within the interval: | a0c0 |

| A3 |

|

a0c0 |

| A3 |

For Class C2 and Class C3 the reference pressure Pr is the For class C2 and class C3 the reference pressure Pr is the inflation pressure corresponding to the DEL indication of the inflation pressure marked on the sidewall as required by paragraph 4.1. of this Regulation. |

a6c0 |

| A3 |

For class C1 the reference pressure is Pr = 250 kPa for "standard" tyres and 290 kPa for "reinforced" or "extra load" tyres; the minimum test pressure shall be Pt = 150 kPa. |

a6c0 |

| A3 2.5.4. | Preparations prior to testing | a0c0 |

| A3 | The tyres shall be "run-in" prior to testing to remove compound nodules or other tyre pattern characteristics resulting from the moulding process. This will normally require the equivalent of about 100 km of normal use on the road. | a0c0 |

| A3 | The tyres fitted to the test vehicle shall rotate in the same direction as when they were run-in. | a0c0 |

| A3 | Prior to testing tyres shall be warmed up by running under test conditions. | a0c0 |

| A3 3. | Method of testing | a0c0 |

| A3 3.1. | General conditions | a0c0 |

| A3 | For all measurements the vehicle shall be driven in a straight line over the measuring section (AA' to BB') in such a way that the median longitudinal plane of the vehicle is as close as possible to the line CC'. | a0c0 |

| A3 | When the front end of the test vehicle has reached the line AA' the vehicle driver shall have put the gear selector on neutral position and switched off the engine. If abnormal noise (e.g. ventilator, self-ignition) is emitted by the test vehicle during the measurement, the test shall be disregarded. | a0c0 |

| A3 3.2. | Nature and number of measurements | a0c0 |

| A3 | The maximum sound level expressed in A-weighted decibels (dB(A)) shall be measured to the first decimal place as the vehicle is coasting between lines AA' and BB' (Figure 1 - front end of the vehicle on line AA', rear end of the vehicle on line BB'). This value will constitute the result of the measurement. | a0c0 |

| A3 | At least four measurements shall be made on each side of the test vehicle at test speeds lower than the reference speed specified in paragraph 4.1. below and at least four measurements at test speeds higher than the reference speed. The speeds shall be approximately equally spaced over the speed range specified in paragraph 3.3. below. | a0c0 |

| A3 3.3. | Test speed range | a0c0 |

| A3 | The test vehicle speeds shall be within the range: | a0c0 |

| A3 |

(a) From 70 to 90 km/h for class C1 and class C2 tyres; |

a6c0 |

| A3 |

(b) From 60 to 80 km/h for class C3 tyres. |

a6c0 |

| A3 4. | Interpretation of results | a0c0 |

| A3 | The measurement shall be invalid if an abnormal discrepancy between the values is recorded (see paragraph 2.3.2. of this annex). | a0c0 |

| A3 4.1. | Determination of test result | a0c0 |

| A3 | Reference speed Vref used to determine the final result will be: | a0c0 |

| A3 |

(a) 80 km/h for class C1 and class C2 tyres; |

a6c0 |

| A3 |

(b) 70 km/h for class C3 tyres. |

a6c0 |

|

A3 4. |

Temperature correction |

a3c0 |

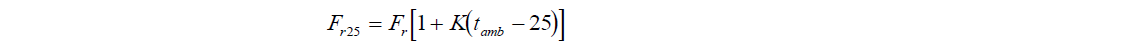

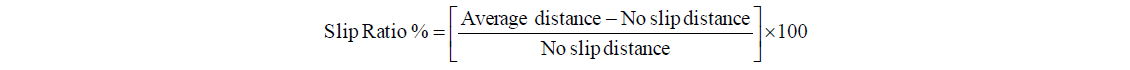

| A3 |

For Class C1 and Class C2 tyres, [DEL] the rolling sound levels Li(&thetasymi) obtained at the test surface temperature &thetasymi (where i denotes the number of the single measurement) shall be normalized to a test surface reference temperature &thetasymref by applying a temperature correction, according to the following formula: |

a3c0 |

| A3 |

|

a3c0 |

| A3 |

Notwithstanding the above procedure, the temperature correction may be made only on the final reported tyre rolling sound level LR, utilizing the arithmetic mean value of the measured temperatures, if the measured test surface temperature does not change more than 5 °C within all measurements necessary for the determination of the sound level of one set of tyres.[DEL] In this case the regression analysis below shall be based on the uncorrected rolling sound levels Li(&thetasymi). There will be no temperature correction for Class C3 tyres. |

a3c0 |

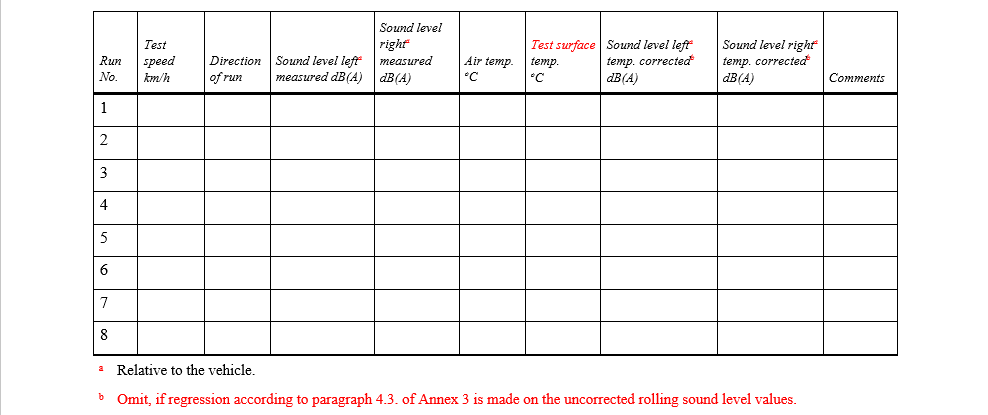

|

A3 4. |

Regression analysis of rolling sound measurements |

a3c0 |

| A3 |

The tyre-road rolling sound level LR(&thetasymref) in dB(A) is determined by a regression analysis according to: |

a3c0 |

| A3 |

|

a3c0 |

| A3 | There will be no temperature correction for Class C3 tyres. | a0c0 |

| A3 4.4. |

In order to take account of any measuring instrument inaccuracies, the temperature corrected tyre rolling sound level LR(&thetasymref) in dB(A) shall be reduced by 1 dB(A) and then rounded down to the nearest lower whole value to obtain the final result. |

a3c0 |

| A3 4.5. |

[DEL] |

a3c0 |

| A3 |

|

a0c0 |

| A3 |

|

a0c0 |

| A3 |

|

a0c0 |

| A3 | Part 1 - Report | a0c0 |

| A3 1. | Type Approval Authority or Technical Service: | a0c0 |

| A3 2. |

Name and address of manufacturer [DEL]: |

a3c0 |

| A3 3. | Test report No.: | a0c0 |

| A3 4. |

[DEL] Brand Name and [DEL] Trade description: |

a3c0 |

| A3 5. | Tyre Class (C1, C2 or C3): | a0c0 |

| A3 6. | Category of use: | a0c0 |

| A3 6.1. |

Snow tyre use in severe snow conditions (Yes/No)1 |

a6c0 |

|

A3 |

Traction tyre (Yes/No)1 |

a3c0 |

| A3 7. |

Sound level according to paragraphs 4.4. [DEL] of Annex 3: ...........dB(A) |

a3c0 |

| A3 | at reference speed of 70/80 km/h[1] | a0c0 |

|

A3 |

|

a0c0 |

| A3 8. | Comments (if any): | a0c0 |

| A3 9. | Date: | a0c0 |

| A3 10. | Signature: | a0c0 |

| A3 | Part 2 - Test data | a0c0 |

| A3 1. | Date of test: | a0c0 |

| A3 2. | Test vehicle (Make, model, year, modifications, etc.): | a0c0 |

| A3 2.1. | Test vehicle wheelbase: mm | a0c0 |

| A3 3. | Location of test track: | a0c0 |

| A3 3.1. | Date of track certification to ISO 10844:2014: | a0c0 |

| A3 3.2. | Issued by: | a0c0 |

| A3 3.3. | Method of certification: | a0c0 |

| A3 4. | Tyre test details: | a0c0 |

| A3 4.1. | Tyre size designation: | a0c0 |

| A3 4.2. | Tyre service description: | a0c0 |

| A3 4.3. |

Reference (test) inflation pressure2: kPa |

a3c0 |

|

A3 |

for classes C2 and C3 tyres, corresponding to the indication of the inflation pressure marked on the sidewall as required by paragraph 4.1. of this Regulation |

a6c0 |

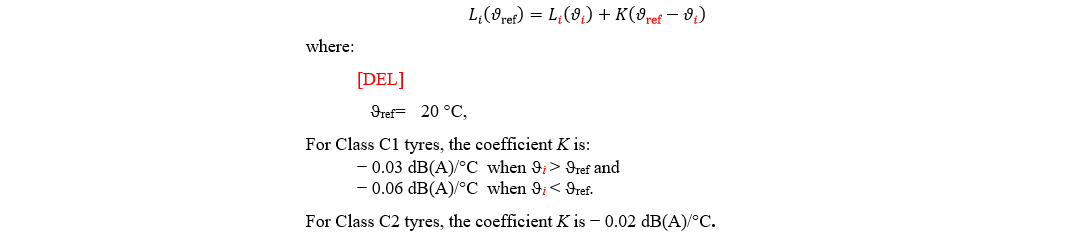

| A3 4.4. | Test data: | a0c0 |

| A3 |

|

a0c0 |

| A3 4.5. | Test rim width code: | a0c0 |

| A3 4.6. | Temperature measurement sensor type: | a0c0 |

| A3 5. | Valid test results: | a0c0 |

| A3 |

|

a3c0 |

| A3 5.1. | Regression line slope: | a0c0 |

| A3 5.2. |

Sound level [DEL] according to paragraph 4.3. of Annex 3: dB(A) |

a3c0 |

| A4 |

Annex 4 |

a0c0 |

| A4 |

|

a0c0 |

|

A4 |

|

a0c0 |

| A4 1. | Introduction | a0c0 |

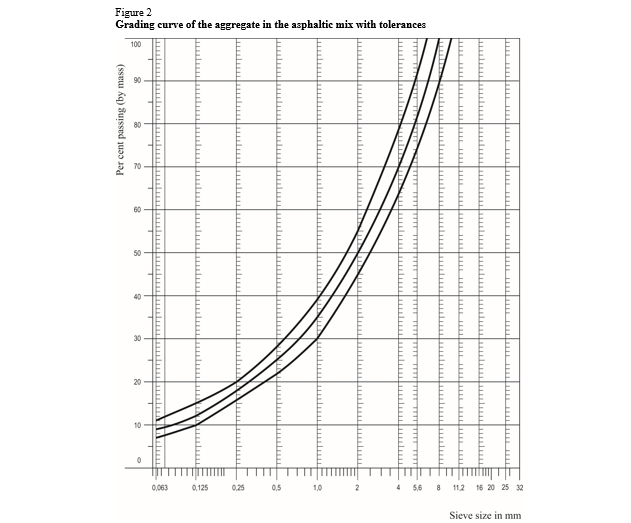

| A4 | This annex describes the specifications relating to the physical characteristics and the laying of the test track. These specifications based on a special standard[2] describe the required physical characteristics as well as the test methods for these characteristics. | a0c0 |

|

A4 |

|

a0c0 |

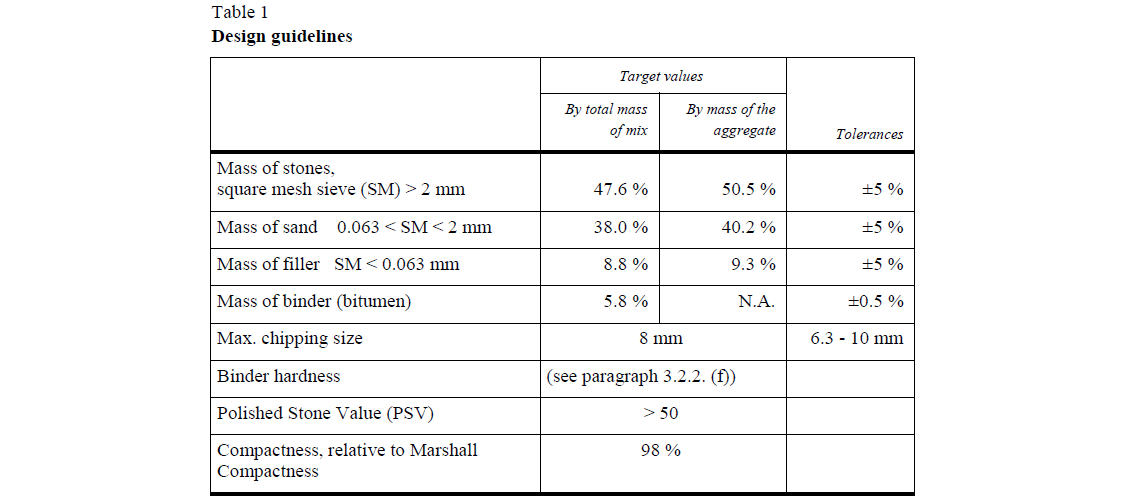

| A4 2. | Required characteristics of the surface | a0c0 |

| A4 | A surface is considered to conform to this standard provided that the texture and voids content or sound absorption coefficient have been measured and found to fulfil all the requirements of paragraphs 2.1. to 2.4. below and provided that the design requirements (paragraph 3.2. below) have been met. | a0c0 |

| A4 2.1. | Residual voids content | a0c0 |

| A4 | The residual Voids Content (VC) of the test track paving mixture shall not exceed 8 per cent. For the measurement procedure, see paragraph 4.1. of this annex. | a0c0 |

| A4 2.2. | Sound absorption coefficient | a0c0 |

| A4 | If the surface fails to comply with the residual voids content requirement, the surface is acceptable only if its sound absorption coefficient is α ≤ 0.10. For the measurement procedure, see paragraph 4.2. below. The requirements of this paragraph 2.1. above are met also if only sound absorption has been measured and found to be α ≤ 0.10. | a0c0 |

| A4 | Note: The most relevant characteristic is the sound absorption, although the residual voids content is more familiar among road constructors. However, sound absorption needs to be measured only if the surface fails to comply with the voids requirement. This is motivated because the latter is connected with relatively large uncertainties in terms of both measurements and relevance and some surfaces therefore erroneously may be rejected when based only on the voids measurement. | a0c0 |

| A4 2.3. | Texture depth | a0c0 |

| A4 | The Texture Depth (TD) measured according to the volumetric method (see paragraph 4.3. below) shall be: | a0c0 |

| A4 | TD ≥ 0.4 mm | a0c0 |

| A4 2.4. | Homogeneity of the surface | a0c0 |

| A4 | Every practical effort shall be taken to ensure that the surface is made to be as homogeneous as possible within the test area. This includes the texture and voids content, but it should also be observed that if the rolling process results in more effective rolling at some places than others, the texture may be different and unevenness causing bumps may also occur. | a0c0 |

| A4 2.5. | Period of testing | a0c0 |

| A4 | In order to check whether the surface continues to conform to the texture and voids content or sound absorption requirements stipulated in this standard, periodic testing of the surface shall be done at the following intervals: | a0c0 |

| A4 | (a) For residual VC or sound absorption (α): | a0c0 |

| A4 | When the surface is new: | a0c0 |

| A4 | If the surface meets the requirements when new, no further periodical testing is required. If it does not meet the requirement when it is new, it may do so later because surfaces tend to become clogged and compacted with time; | a0c0 |

| A4 | (b) For TD: | a0c0 |

| A4 | When the surface is new: | a0c0 |

| A4 | When the noise testing starts (Note: Not before four weeks after laying); | a0c0 |

| A4 | Then every twelve months. | a0c0 |

| A4 3. | Test surface design | a0c0 |

| A4 3.1. | Area | a0c0 |

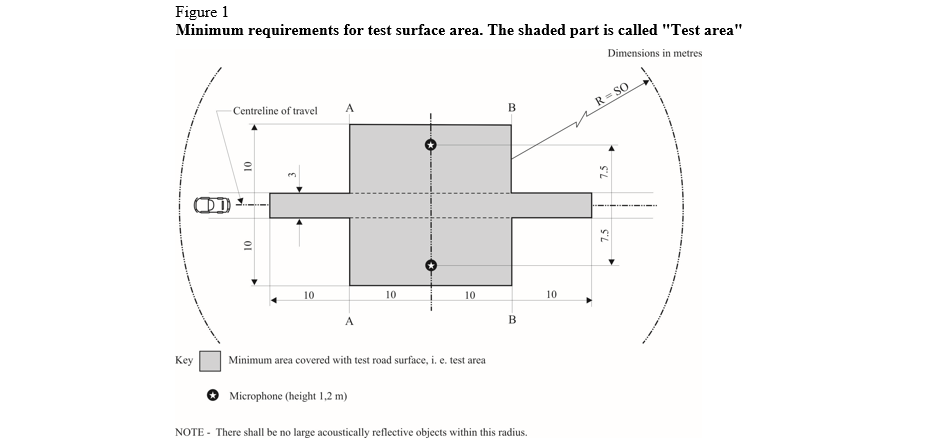

| A4 | When designing the test track layout it is important to ensure that, as a minimum requirement, the area traversed by the vehicles running through the test strip is covered with the specified test material with suitable margins for safe and practical driving. This will require that the width of the track is at least 3 m and the length of the track extends beyond lines AA and BB by at least 10 m at either end. Figure 1 shows a plan of a suitable test site and indicates the minimum area which shall be machine laid and machine compacted with the specified test surface material. According to Annex 3, paragraph 3.2., measurements have to be made on each side of the vehicle. This can be made either by measuring with two microphone locations (one on each side of the track) and driving in one direction, or measuring with a microphone only on one side of the track but driving the vehicle in two directions. If the latter method is used, then there are no surface requirements on that side of the track where there is no microphone. | a0c0 |

| A4 |

|

a0c0 |

| A4 3.2. | Design and preparation of the surface | a0c0 |